Method for preparing vitamin E acetate

A vitamin and acetate technology, which is applied in the field of vitamin E acetate preparation, can solve the problems of catalyst corrosion to equipment, difficult process waste liquid treatment, and increased unit consumption of materials, so as to improve reaction activity and product selectivity , Improve the conversion rate and selectivity, and improve the effect of antioxidant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

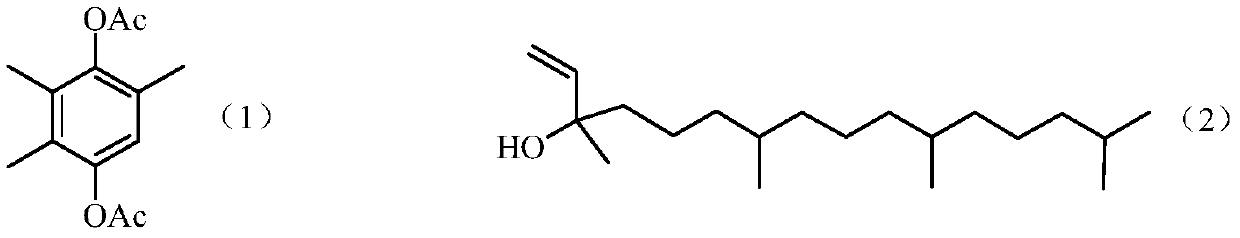

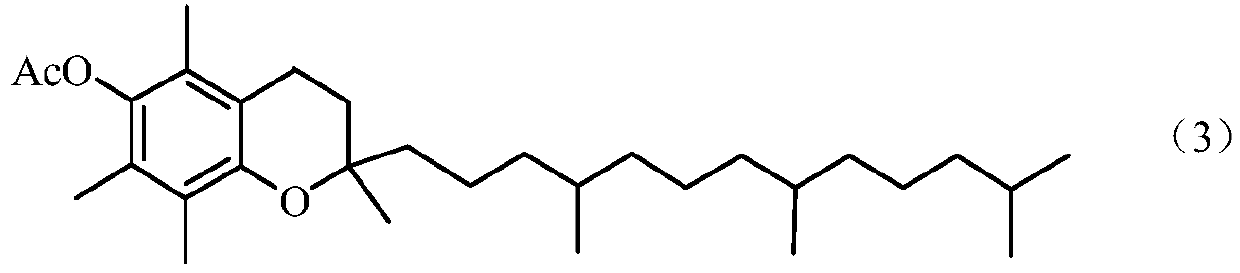

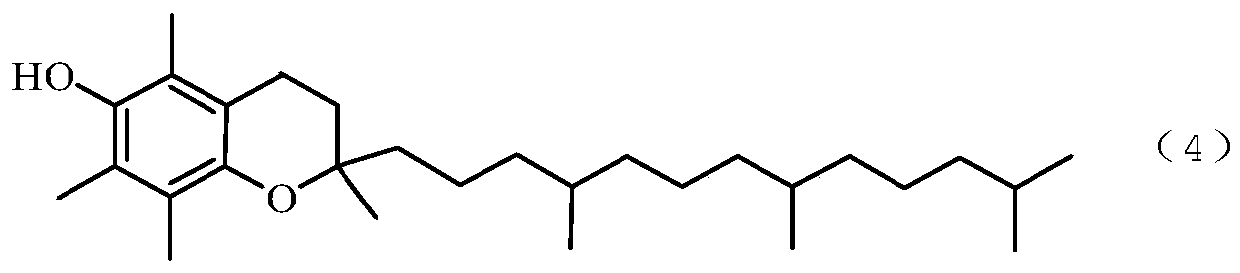

Method used

Image

Examples

Embodiment 1

[0056] Catalyst 1 preparation method is as follows:

[0057] In this example, self-made MCM-48 molecular sieves are used, and the preparation process is as follows: Take 10 g of cetyltrimethylammonium bromide (CTAB) and add it to 100 g of pure water, then add 110 g of methanol and 20 g of concentrated ammonia water (with a concentration of 25 wt % ), after ultrasonication at room temperature for 30 minutes, 15 g of tetraethyl orthosilicate (TEOS) was added dropwise, after ultrasonication at room temperature for 30 minutes, filtered by suction and washed with pure water until pH = 7, dried at 120°C for 2 hours and ground into powder, then placed Roast in a muffle furnace at 800°C for 4 hours to obtain MCM-48 molecular sieve.

[0058] Catalyst intermediate preparation: under the condition of nitrogen protection, 1.25g FeCl 2 , Add 1.25g titanocene dichloride and 1.0g nano-scale Fe particles into 400g pure water, stir and mix thoroughly at room temperature, add 60g of the prepar...

Embodiment 2-7

[0062] The preparation method of catalyst 2-7 (CAT-2-7) is basically the same as that of catalyst 1 (CAT-1), the difference lies in the ratio of materials, the ratio of materials and the detailed material composition are shown in Table 1 below:

[0063] MCM-48 molecular sieve preparation raw material formula table in table 1 catalyst 2-7

[0064]

[0065]

[0066] Table 2 Catalyst 2-7 preparation raw material formula table

[0067]

Embodiment 8

[0069] Add 70.0g of TMHQ-DA, 30.2g of acetic anhydride and 142.3g of glacial acetic acid into a 500mL three-necked flask, heat to 70°C to completely dissolve TMHQ-DA, start stirring, add 1.40g of catalyst 1 (CAT-1), and then start to drop IPL (87.9g) was added dropwise for 120 minutes, and the reaction was continued for 60 minutes after the addition was completed. After the reaction was completed, sampling and analysis showed that the conversion rate of raw material TMHQ-DA was 99.8%, and the selectivity of product vitamin E acetate was 98.8%. Stirring was stopped, and after standing for 3 minutes, the reaction liquid was divided into two layers, the upper layer was the vitamin E acetate product phase, and the lower layer was the catalyst and solvent phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com