Preparation method for vinyl tris(trimethylsiloxane)silane

A technology of ethoxytrimethylsilane and vinyltriethoxysilane, which is applied in the field of preparation of vinyltrisilane, can solve the problems of too fast product hydrolysis, severe reaction heat release, complex process flow, etc. Simple, easy to remove, and the effect of improving the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

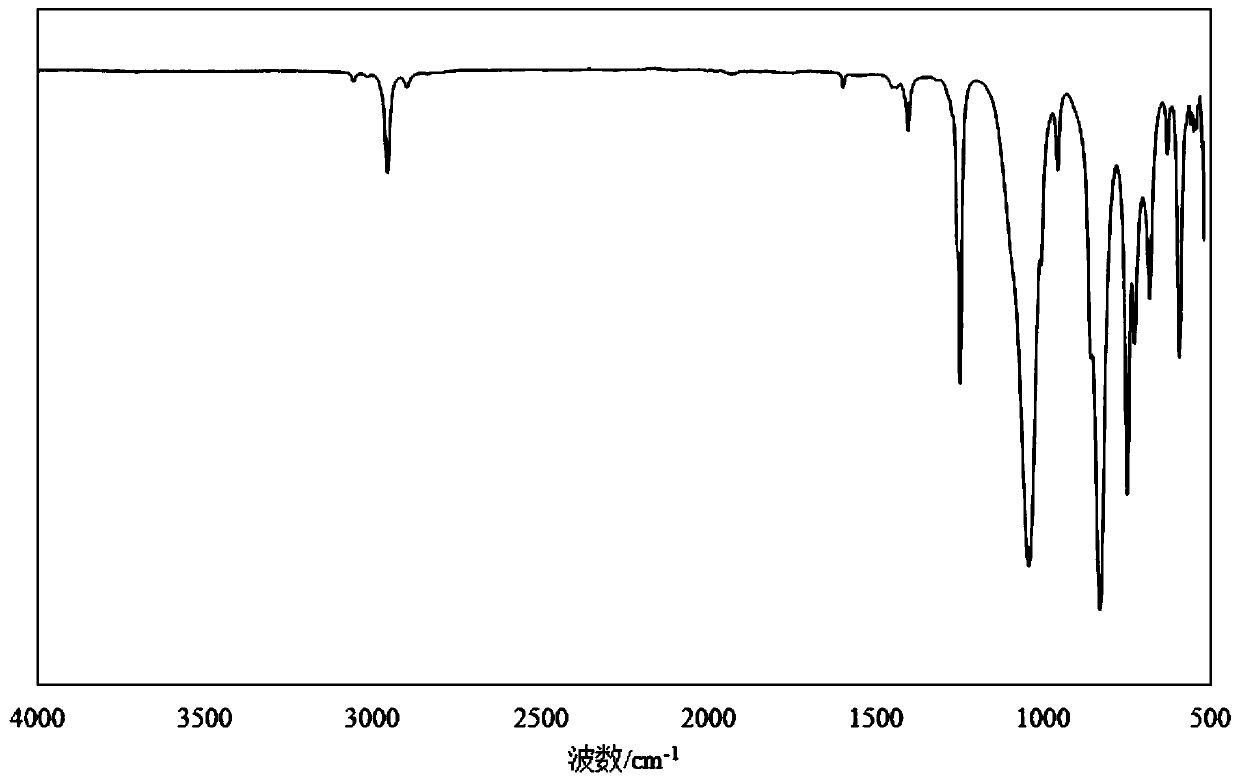

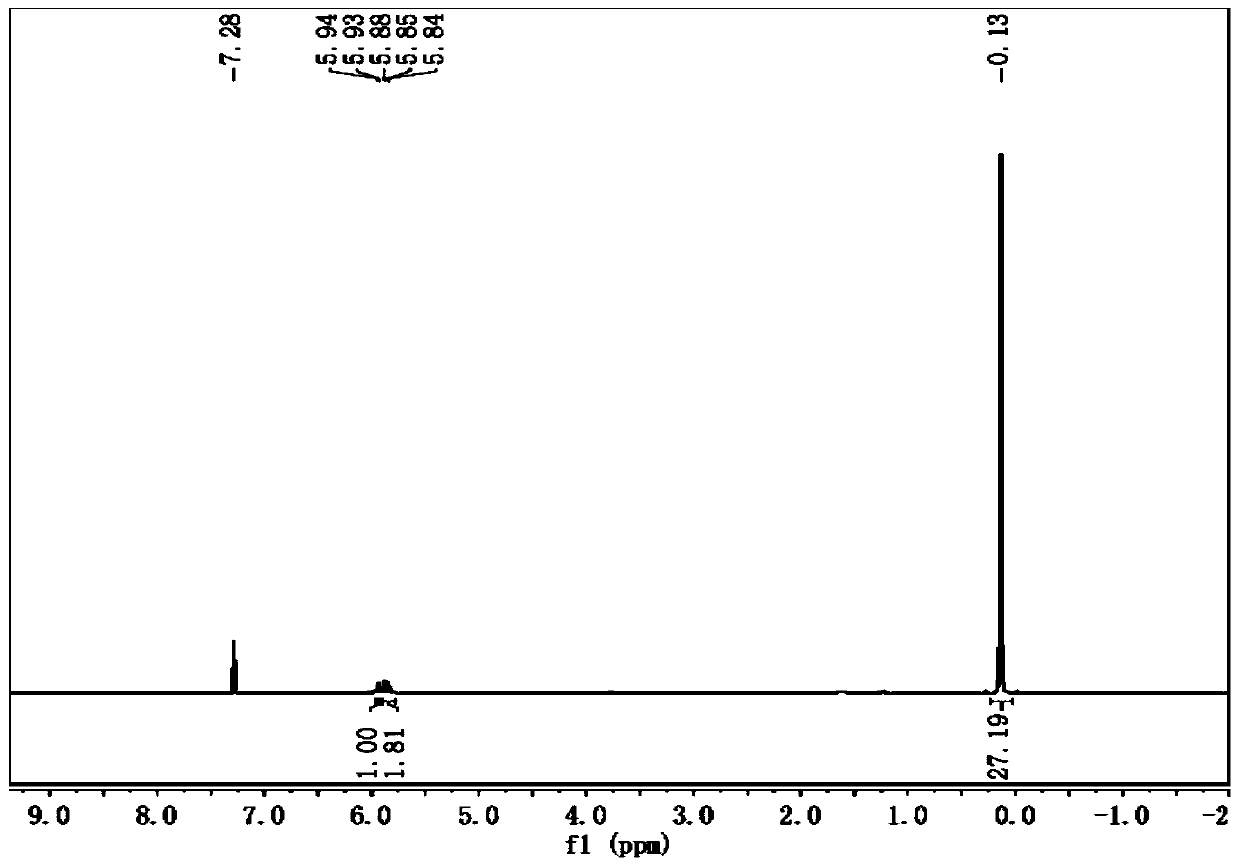

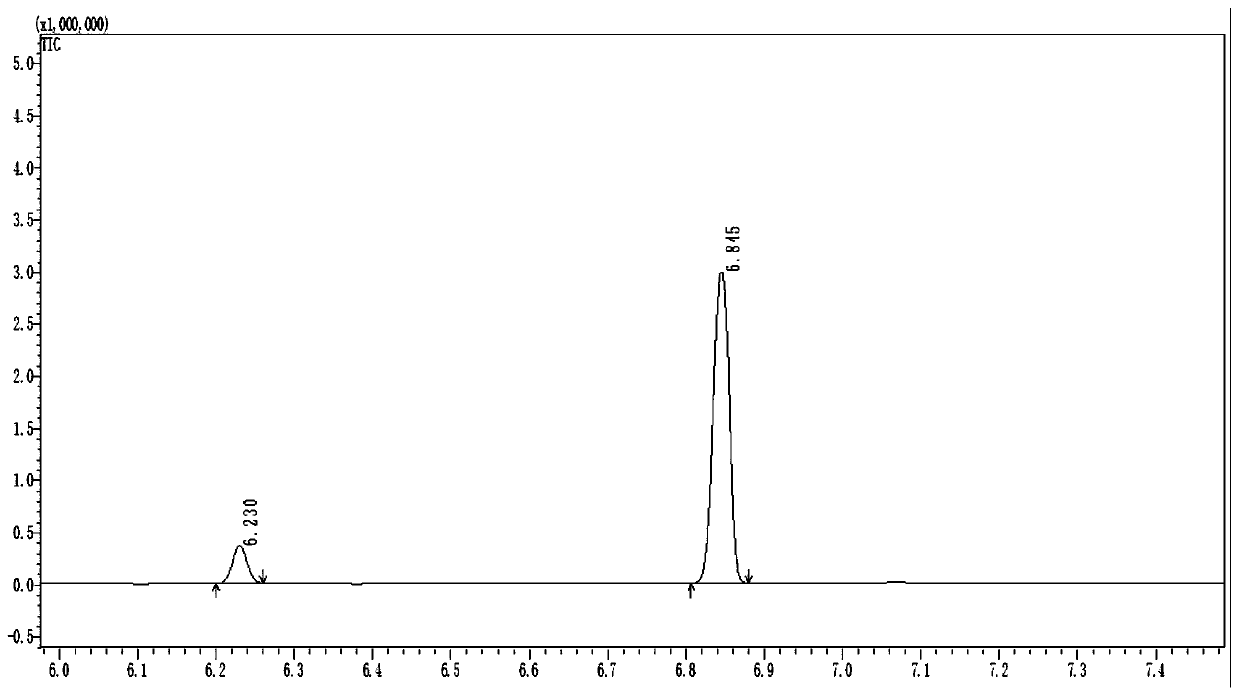

[0038] The reaction flask containing 30 g of vinyltriethoxysilane was placed in a constant temperature magnetic stirring device. Stir and heat to 60°C, slowly add 11.2ml, 0.001mol / L hydrochloric acid solution and 67.12g ethoxytrimethylsilane dropwise with a constant pressure dropping funnel, after the dropwise addition is completed, react at a constant temperature, condense and reflux for 2.5h, and the reaction ends , to obtain the crude product. Vacuum rotary evaporation at 70°C to remove ungrafted reaction raw materials, ethanol, water and other low-boiling impurities. Extract with an appropriate amount of toluene, wash twice with sodium carbonate, wash repeatedly with deionization, separate the funnel for stratification, take the toluene layer until the pH value is neutral, dry with anhydrous sodium sulfate for 1 hour, and finally use The organic layer was distilled under reduced pressure, and the fraction with a temperature of 130-140° C. and a vacuum of -0.09 MPa was tak...

Embodiment 2

[0047] Place a reaction bottle containing 50ml of solvent toluene and 12g of vinyltriethoxysilane in a constant temperature magnetic stirring device, stir and heat to 55°C, and mix well. Slowly add 10.43ml of 0.01mol / L hydrochloric acid aqueous solution and 34.44g of ethoxytrimethylsilane dropwise with a constant pressure dropping funnel. After the dropwise addition, react at constant temperature, condense and reflux for 3 hours, and the crude product is obtained after the reaction is completed. Rotary steaming at 70°C to remove ungrafted reaction raw materials, ethanol, water, solvent toluene and other low-boiling impurities. Extract with toluene, wash with appropriate amount of sodium carbonate twice, deionize and wash repeatedly, separate the funnel for stratification, take the toluene layer, repeat until the pH value is neutral, dry with anhydrous sodium sulfate for 1 hour, and finally use reducing Distill the organic layer under pressure, and take the fraction whose tempe...

Embodiment 3

[0050] Place the reaction flask containing 12 g of vinyltriethoxysilane in a constant temperature magnetic stirring device, stir and heat to 30° C., and mix well. Prepare 0.01mol / L dilute hydrochloric acid solution. Slowly add 10.43ml of hydrochloric acid aqueous solution and 34.44g of ethoxytrimethylsilane dropwise with a constant pressure dropping funnel. After the dropwise addition, react at constant temperature, condense and reflux for 1 hour, and the crude product is obtained after the reaction is completed. Rotary steaming at 70°C to remove ungrafted reaction raw materials, ethanol, water, and other low-boiling impurities. Extract with toluene, wash with appropriate amount of sodium carbonate twice, deionize and wash repeatedly, separate the funnel for stratification, take the toluene layer, repeat until the pH value is neutral, dry with anhydrous sodium sulfate for 1 hour, and finally use reducing The organic layer was distilled under pressure, and the fraction tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com