Environment-friendly phenolic resin adhesive as well as preparation method and application thereof

A phenolic resin glue, an environmentally friendly technology, applied in the direction of adhesives, adhesive types, aldehyde/ketone condensation polymer adhesives, etc. The effect of reaction process, improving environmental protection and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

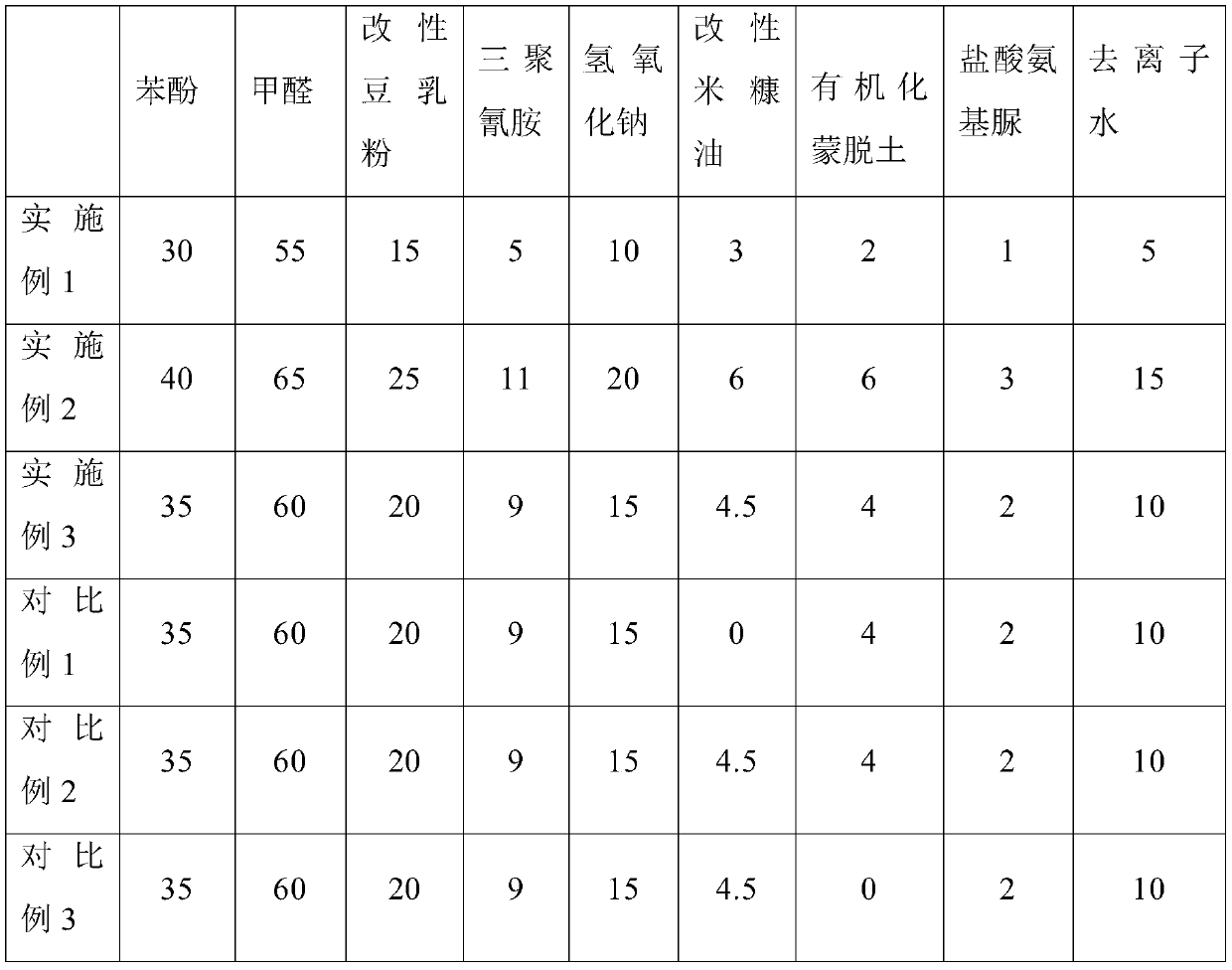

Embodiment 1

[0031] A kind of environment-friendly phenolic resin glue of the present embodiment comprises the raw material of following weight portion:

[0032] 30 parts of phenol, 55 parts of formaldehyde, 15 parts of modified soybean milk powder, 5 parts of melamine, 10 parts of sodium hydroxide, 3 parts of modified rice bran oil, 2 parts of organic montmorillonite, 1 part of semicarbazide hydrochloride, 5 parts of deionized water share;

[0033] The preparation method of the modified soy milk powder is as follows: the soy milk powder is irradiated with cobalt-60 gamma rays for 2 seconds, and the irradiation dose is 3KGy, then added to deionized water for ultrasonic dispersion for 10 minutes, and then added ammonia solution to adjust the pH to 8.5, then add glucomannan with 10% of the total amount of soybean milk powder, then concentrate in vacuum, dry, and then send it into the air explosion tank, feed steam until the pressure is 2.6MPa, keep the pressure for 20s, and then put the reac...

Embodiment 2

[0044] A kind of environment-friendly phenolic resin glue of the present embodiment comprises the raw material of following weight portion:

[0045] 40 parts of phenol, 65 parts of formaldehyde, 25 parts of modified soybean milk powder, 11 parts of melamine, 20 parts of sodium hydroxide, 6 parts of modified rice bran oil, 6 parts of organic montmorillonite, 3 parts of semicarbazide hydrochloride, 15 parts of deionized water share;

[0046] The preparation method of the modified soybean milk powder is as follows: the soybean milk powder is irradiated with cobalt-60 gamma rays for 5 seconds, and the radiation dose is 6KGy, then added to deionized water for ultrasonic dispersion for 20 minutes, and then added ammonia solution to adjust the pH to 9.5, then add glucomannan with 20% of the total amount of soy milk powder, then concentrate in vacuum, dry, and then send it into the air explosion tank, feed steam until the pressure is 3.0MPa, keep the pressure for 30s, and then put the...

Embodiment 3

[0057] A kind of environment-friendly phenolic resin glue of the present embodiment comprises the raw material of following weight portion:

[0058] 35 parts of phenol, 60 parts of formaldehyde, 20 parts of modified soybean milk powder, 8 parts of melamine, 15 parts of sodium hydroxide, 4.5 parts of modified rice bran oil, 4 parts of organic montmorillonite, 2 parts of semicarbazide hydrochloride, 10 parts of deionized water share;

[0059] The preparation method of the modified soybean milk powder is as follows: the soybean milk powder is first irradiated with cobalt-60 gamma rays for 3.5 seconds, and the radiation dose is 4.5KGy, then added to deionized water for ultrasonic dispersion for 15 minutes, and then added ammonia solution to adjust pH to 9.0, then add glucomannan with 15% of the total amount of soybean milk powder, then concentrate in vacuum, dry, and then send it into the air explosion tank, feed steam to the pressure of 2.8MPa, keep the pressure for 25s, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com