Separation method of copper-nickel alloy and application

A copper-nickel alloy and separation method technology, which is applied to the improvement of process efficiency, photography process, electrodes, etc., can solve the problems of small application range of ion exchange method, inability to obtain elemental copper, and complicated vulcanization process, and achieves energy consumption cost. Low cost, low cost and high raw material recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

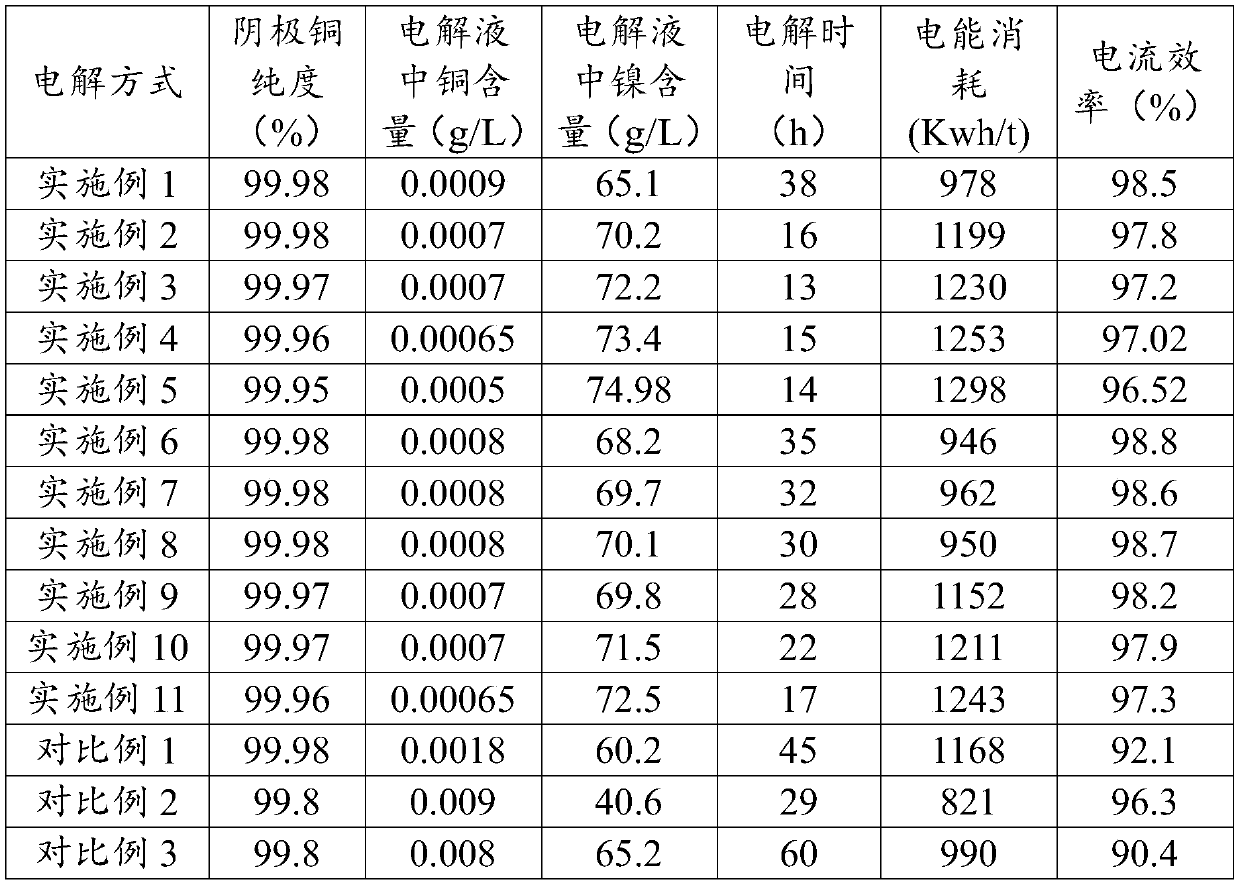

Examples

Embodiment 1

[0076] The present embodiment provides a kind of separation method of copper-nickel alloy, comprises the following steps:

[0077] The nickel-copper alloy metal is placed in a titanium anode basket as the anode, the pure copper rod is used as the cathode, the cathode surface area is 5% of the anode surface area, and the sulfuric acid solution with a total acid concentration of 150g / L is used as the electrolyte, and the electrolyte is circulated. The cathode and anode are placed in the electrolytic cell for normal temperature electrolysis, the distance between different poles is controlled to be 30mm, the circulation flow rate is 1.2m3 / h, the cell voltage is adjusted to 0.8V, and the cathode current density is 1000A / m2. When electrifying for 38 hours, turn off the DC power supply and the electrolyte circulation pump to complete the separation of nickel and copper.

Embodiment 2

[0079] The present embodiment provides a kind of separation method of copper-nickel alloy, comprises the following steps:

[0080] The nickel-copper alloy metal is placed in a titanium anode basket as the anode, the pure copper rod is used as the cathode, the cathode surface area is 6% of the anode surface area, and the sulfuric acid solution with a total acid concentration of 160g / L is used as the electrolyte, and the electrolyte is circulated. The cathode and anode are placed in the electrolytic cell for normal temperature electrolysis, the distance between different poles is controlled to be 30mm, the circulation flow rate is 1.2m3 / h, the cell voltage is adjusted to 1.32V, and the cathode current density is 2700A / m2. When electrifying for 16 hours, turn off the DC power supply and the electrolyte circulation pump to complete the separation of nickel and copper.

Embodiment 3

[0082] The present embodiment provides a kind of separation method of copper-nickel alloy, comprises the following steps:

[0083] The nickel-copper alloy metal is placed in a titanium anode basket as the anode, the pure copper rod is used as the cathode, the cathode surface area is 7% of the anode surface area, and the sulfuric acid solution with a total acid concentration of 170g / L is used as the electrolyte, and the electrolyte is circulated. The cathode and anode are placed in the electrolytic cell for normal temperature electrolysis, the distance between different electrodes is controlled to be 30mm, the circulation flow rate is 1.2m3 / h, the cell voltage is adjusted to 1.62V, and the cathode current density is 3500A / m2. When electrifying for 13 hours, turn off the DC power supply and the electrolyte circulation pump to complete the separation of nickel and copper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com