A kind of porous cobalt sulfide nanoflower and its preparation method and application

A technology of cobalt sulfide and nanoflowers, which is applied in the fields of chemical instruments and methods, cobalt compounds, inorganic chemistry, etc., can solve the problems such as the difficulty in preparing three-dimensional porous cobalt sulfide, and achieve good industrialization prospects, excellent charge and discharge performance, and simple operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

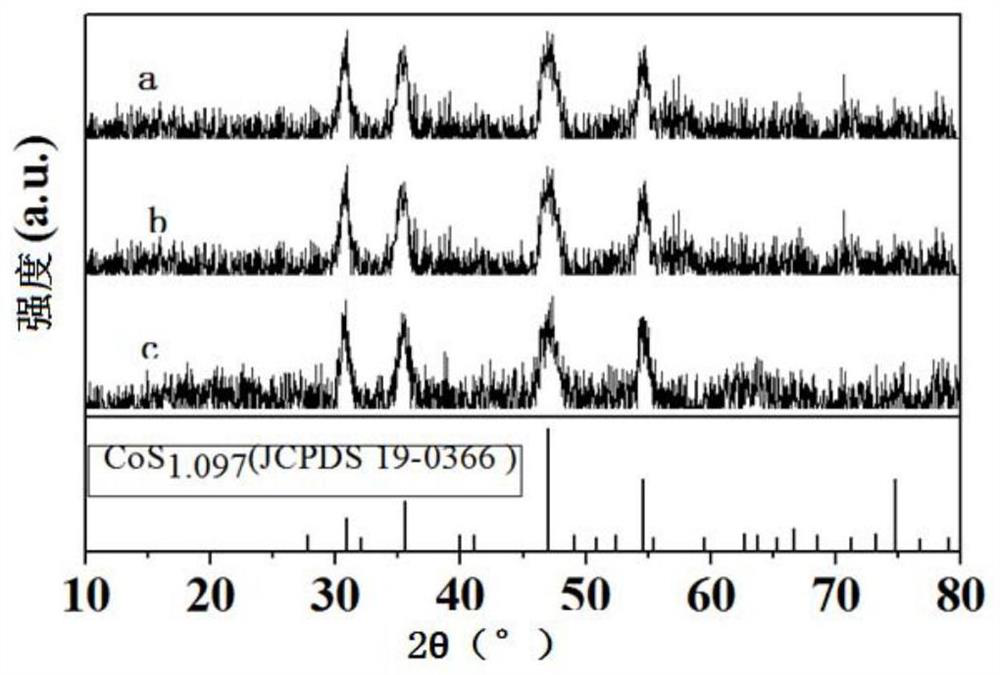

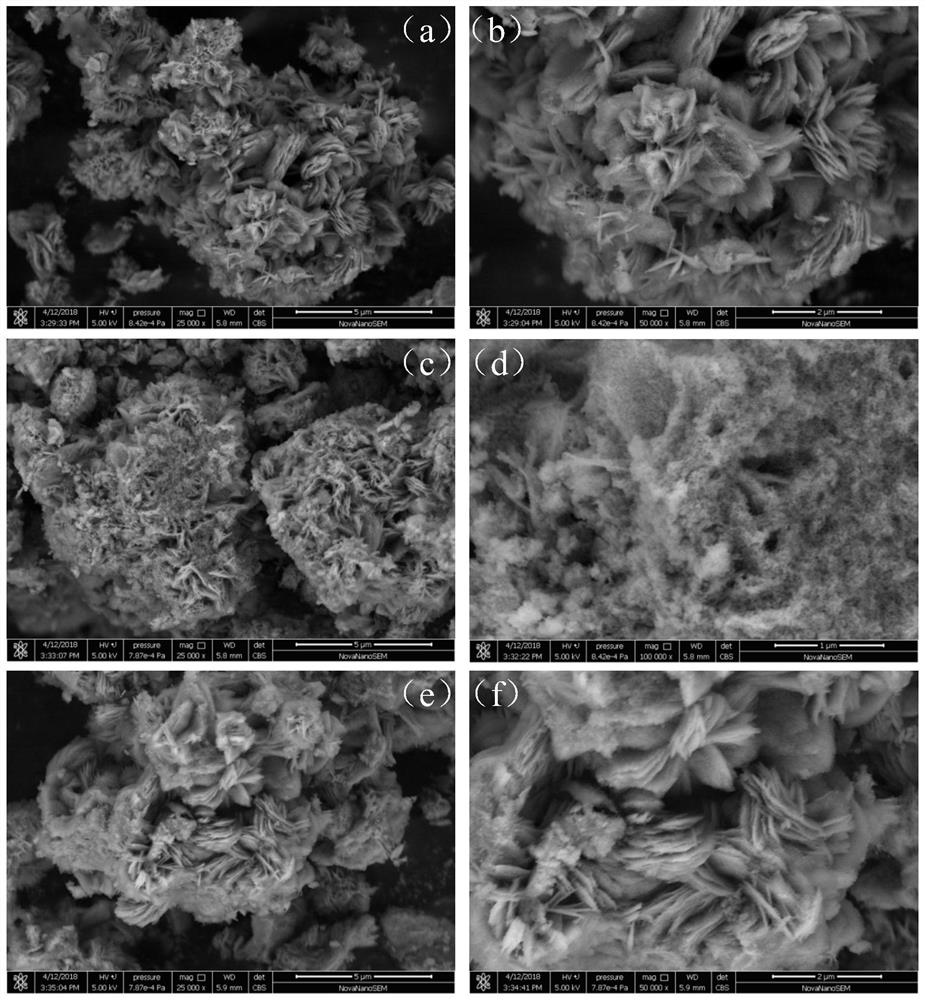

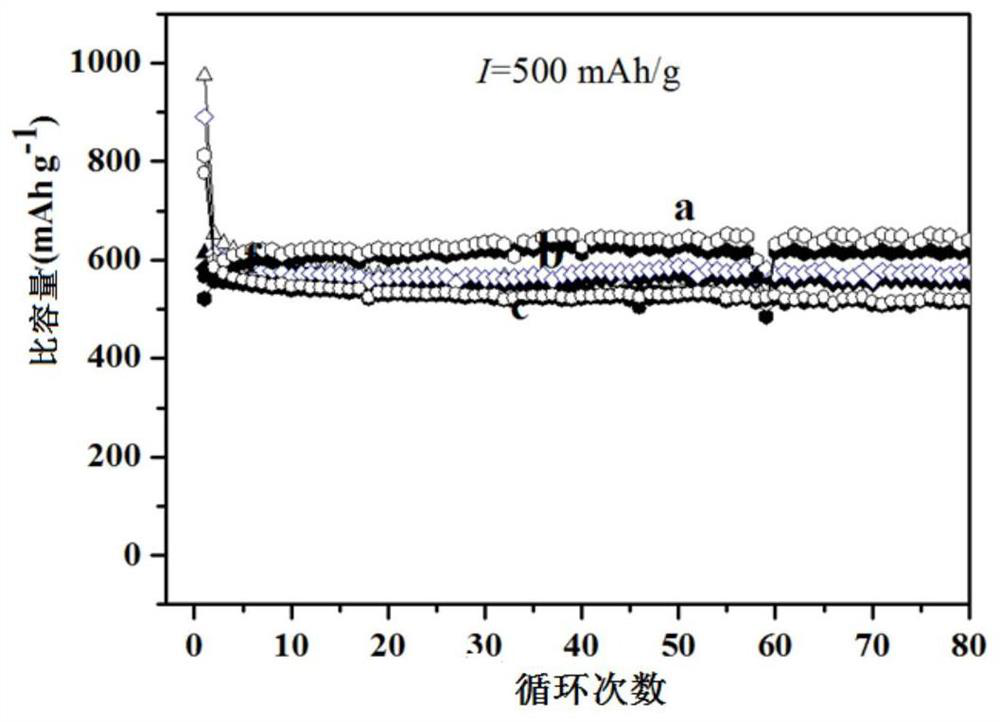

Embodiment 1

[0031] (1) Prepare 200mL of a mixed solution of absolute ethanol and water, and the ratio of water to ethanol is 9:1.

[0032] (2) 0.582g of cobalt nitrate hexahydrate, 5g of urea, 0.3g of PVP (average molecular weight 8000),

[0033] Disperse 0.3g of P123 in the above mixed solution, sonicate for 20min until completely dissolved; then add 0.5g of L-cysteine, and ultrasonically stir until completely dissolved;

[0034] (3) Transfer the above mixed solution to a reaction flask with a reflux condensation device at 85°C for 6h;

[0035] (4) The material obtained after the above reaction is collected by filtration, and after repeated cleaning, it is vacuum-dried to obtain a black powder, which is put into a tube furnace and sintered at a high temperature of 500 ° C for 6 h under an inert atmosphere Ar to prepare porous cobalt sulfide nanoparticles. flower material.

[0036] (5) After fully grinding the sintered material, mix it with carbon black and carboxymethyl cellulose in a ...

Embodiment 2

[0038] (1) Prepare 200mL of a mixed solution of absolute ethanol and water, and the ratio of water to ethanol is 8:1.

[0039] (2) Disperse 0.145g of cobalt nitrate hexahydrate, 2.9g of urea, 0.29g of PVP (average molecular weight 8000), and 0.29g of P123 in the above mixed solution, and ultrasonically 20min until completely dissolved; then add 0.29g of L-cysteine Acid, ultrasonically stirred until completely dissolved;

[0040] (3) Transfer the above mixed solution to a reaction flask with a reflux condensation device at 120°C for 3h;

[0041] (4) The material obtained after the above reaction is collected by filtration, and after repeated cleaning, it is vacuum-dried to obtain a black powder, which is put into a tube furnace and sintered at a high temperature of 400 ° C for 6 h under an inert atmosphere Ar to prepare porous cobalt sulfide nanoparticles. flower material.

[0042] (5) After fully grinding the sintered material, mix it with carbon black and carboxymethyl cell...

Embodiment 3

[0044] (1) Prepare 200mL of a mixed solution of absolute ethanol and water, and the ratio of water to ethanol is 10:1.

[0045] (2) Disperse 1.45g of cobalt nitrate hexahydrate, 1.45g of urea, 0.29g of PVP (average molecular weight 8000), and 0.29g of P123 in the above mixed solution, and ultrasonically 20min until completely dissolved; then add 2.9g of L-cysteine Acid, ultrasonically stirred until completely dissolved;

[0046] (3) Transfer the above mixed solution to a hydrothermal reaction kettle at 100°C for 24h;

[0047](4) The material obtained after the above reaction is collected by filtration, and after repeated cleaning, it is vacuum-dried to obtain a black powder. The powder is put into a tube furnace and sintered at 600 ° C for 3 h in an inert atmosphere to prepare porous cobalt sulfide nanoparticles. flower material.

[0048] (5) After fully grinding the sintered material, mix it with carbon black and carboxymethyl cellulose in a ratio of 70:15:15, and dry it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com