Method for treating bamboo wood heat treatment wastewater

A technology of wood heat treatment and treatment method, which is applied in the field of treatment of bamboo wood heat treatment wastewater, and can solve the problems of low utilization rate of light energy, difficulty in realizing engineering, and difficulty in wastewater pretreatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

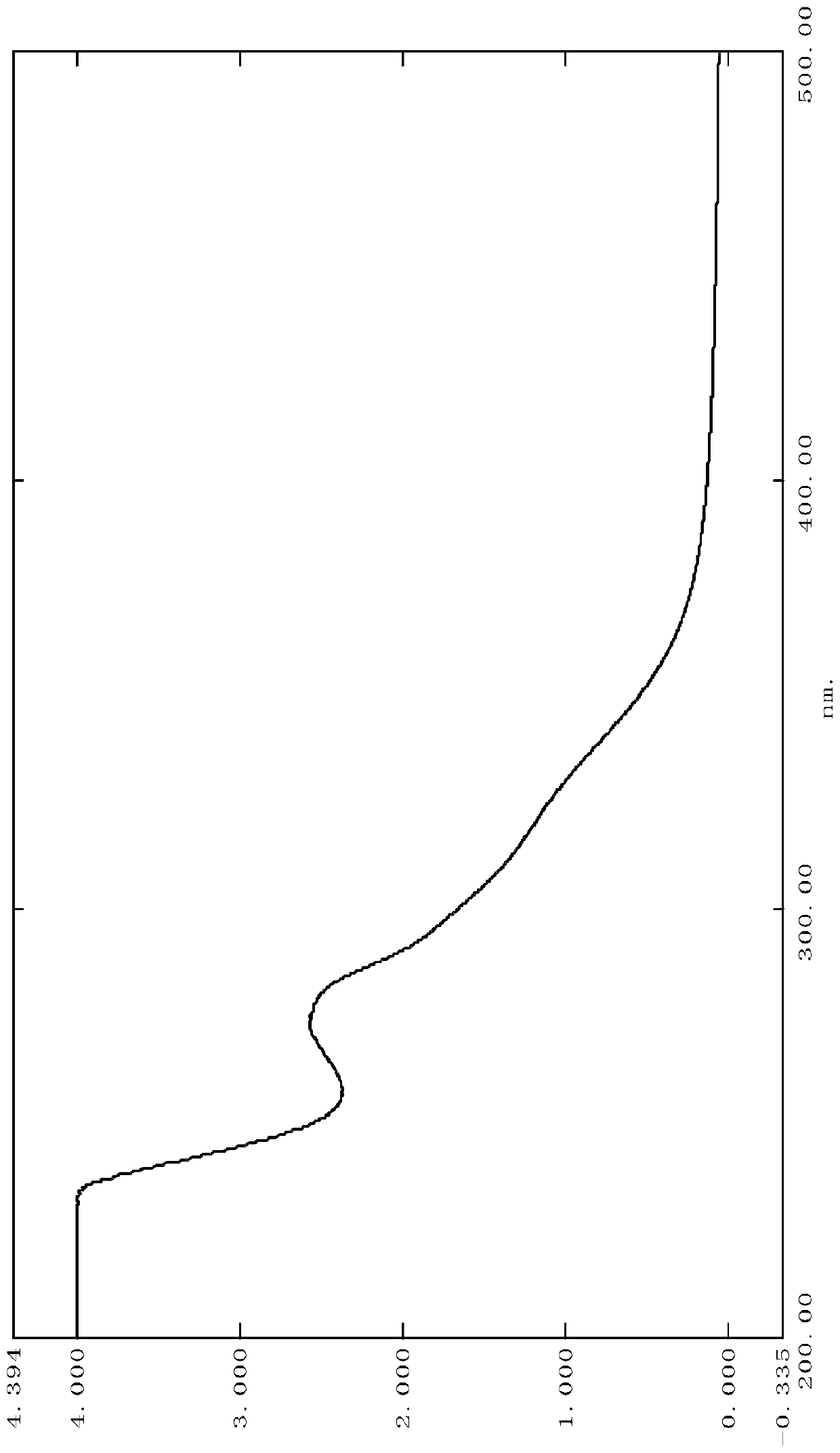

Embodiment 1

[0061] Raw bamboo wood heat treatment wastewater parameters: pH value 4.3, COD 21560mg / L, BOD 1850mg / L, B / C 0.086, chroma 2280, total sugar 17.54g / L, total nitrogen 131.2mg / L, TOC It is 4.62g / L.

[0062] Add a composite catalyst composed of acetic acid and 2mol / L hydrochloric acid (the mass ratio of acetic acid and hydrochloric acid is 1:4) to adjust the pH value of the wastewater to 3.8; continue to add 12wt% sodium hypochlorite aqueous solution, the addition amount is 1g / L. The obtained mixed solution is added into the cavity filled with the carrier, so that the total filling amount of the waste water after the acid treatment, the oxidizing agent and the carrier mixture is 90%. Wherein, the carrier powder is nano-titanium dioxide and subnano-level kaolin, the mass ratio of nano-titanium dioxide and sub-nano-level kaolin is 8:1, and the loading amount of the carrier powder is 10%.

[0063] Start the equipment for oxidative catalytic cracking: the treatment time is 10 minutes...

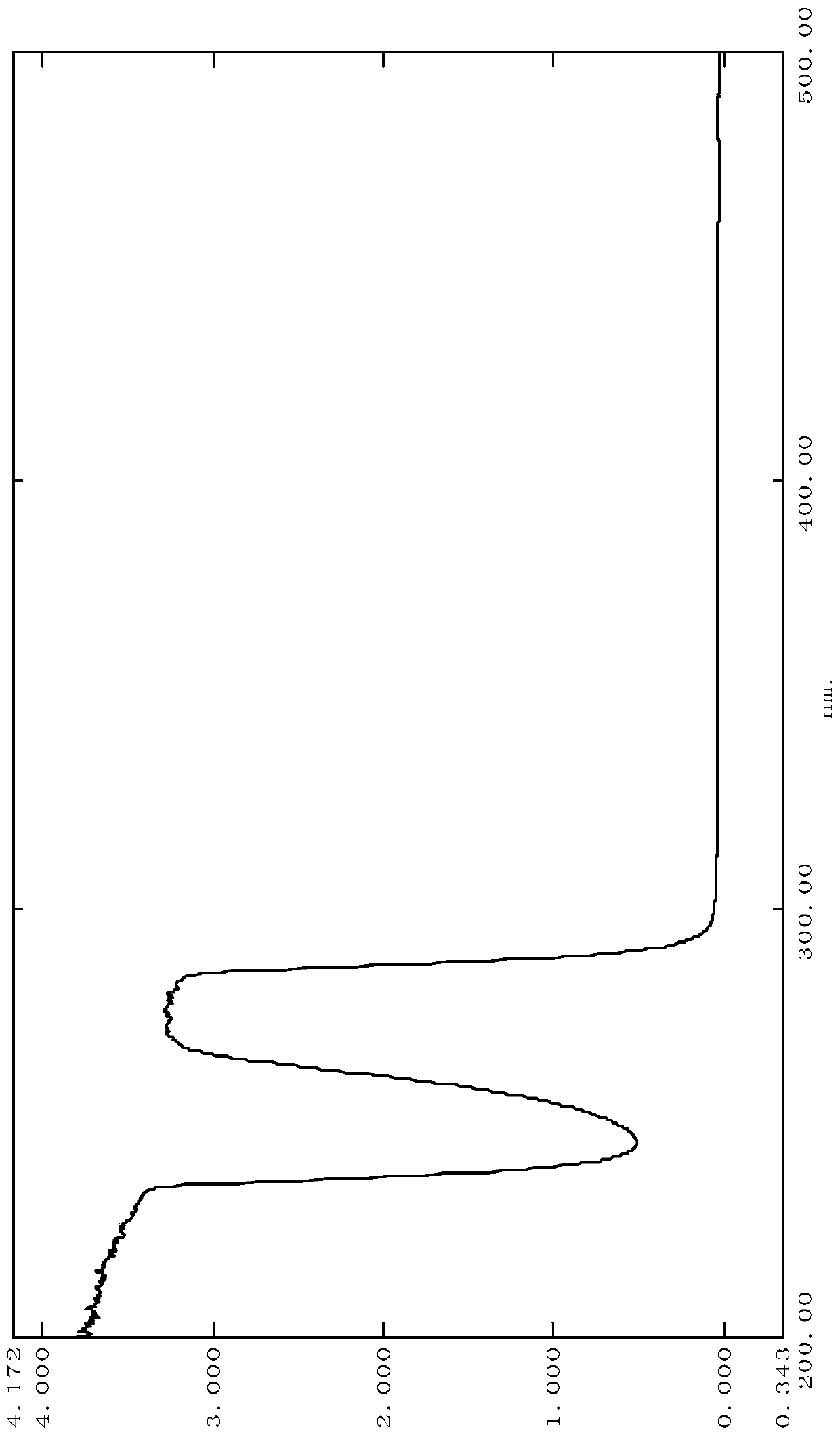

Embodiment 2

[0067] Raw bamboo wood heat treatment wastewater parameters: pH value 4.6, COD 20150mg / L, BOD 2370mg / L, B / C 0.118, chroma 2030, total sugar 19.03g / L, total nitrogen 119.8mg / L, TOC It is 4.55g / L.

[0068] Add a composite catalyst composed of acetic acid and 3mol / L sulfuric acid (the mass ratio of acetic acid and sulfuric acid is 1:3) to adjust the pH value of the wastewater to 3.9; continue to add 12wt% sodium hypochlorite aqueous solution in an amount of 0.8g / L. The obtained mixed solution is added into the cavity filled with the carrier, so that the total filling amount of the waste water after the acid treatment, the oxidizing agent and the carrier mixture is 90%. Wherein, the carrier powder is nano-titanium dioxide and subnano-level kaolin, the mass ratio of nano-titanium dioxide and sub-nano-level kaolin is 6:1, and the loading amount of the carrier powder is 8%.

[0069] Start the equipment for oxidative catalytic cracking: the treatment time is 15 minutes, the treatment...

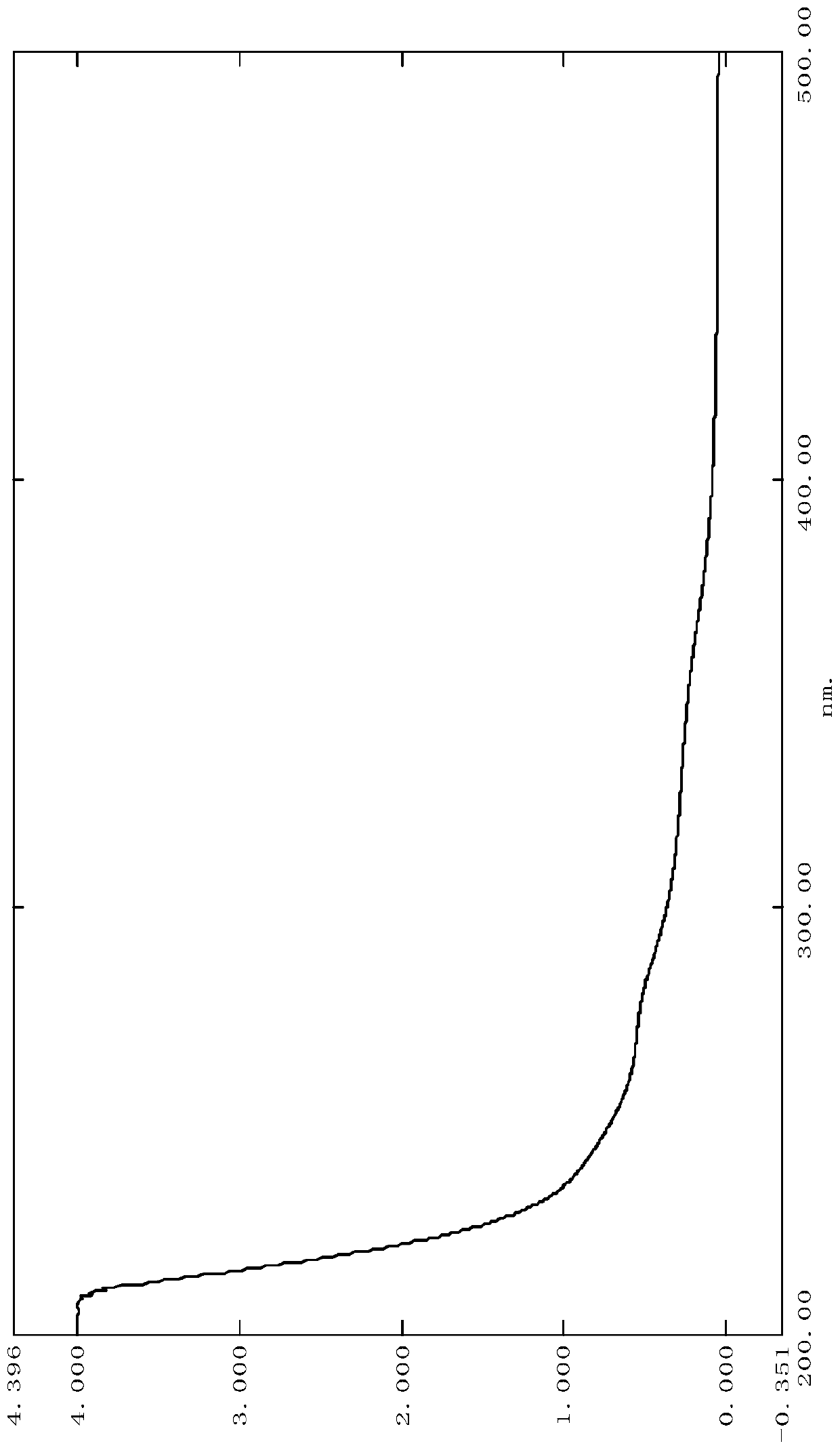

Embodiment 3

[0072] Raw bamboo wood heat treatment wastewater parameters: pH value 4.0, COD 24290mg / L, BOD 2540mg / L, B / C 0.105, chroma 2360, total sugar 20.23g / L, total nitrogen 236.5mg / L, TOC It is 4.73g / L.

[0073] Add a composite catalyst composed of acetic acid and 2mol / L sulfuric acid (the mass ratio of acetic acid and sulfuric acid is 1:4) to adjust the pH value of the wastewater to 4.1; continue to add 12wt% sodium hypochlorite aqueous solution in an amount of 1.1g / L. The obtained mixed solution is added into the cavity filled with the carrier, so that the total filling amount of the waste water after the acid treatment, the oxidizing agent and the carrier mixture is 90%. Wherein, the carrier powder is nano-titanium dioxide and subnano-level kaolin, the mass ratio of nano-titanium dioxide and sub-nano-level kaolin is 9:1, and the loading amount of the carrier powder is 7%.

[0074] Start the equipment for oxidative catalytic cracking: the treatment time is 20min, the treatment temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com