Deep-sea fish collagen peptide and production method thereof

A fish collagen peptide and collagen peptide technology, applied in the field of collagen peptide, can solve the problems of low enzymatic hydrolysis efficiency, complicated operation, acid and alkali resistance, etc., and achieve low free amino acid content, simplified process steps, and not easy to absorb moisture. block effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

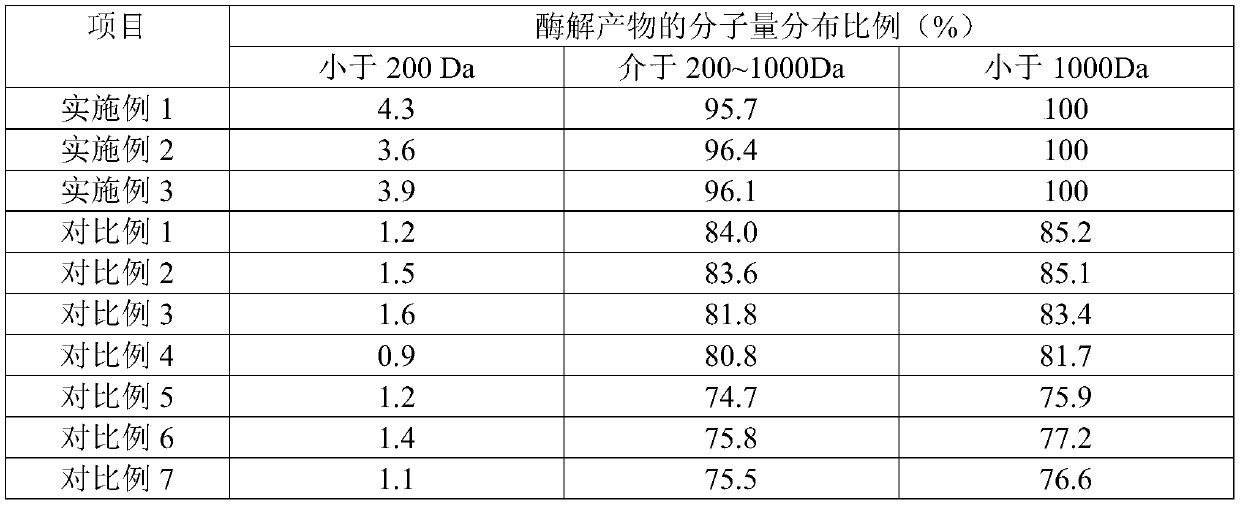

Examples

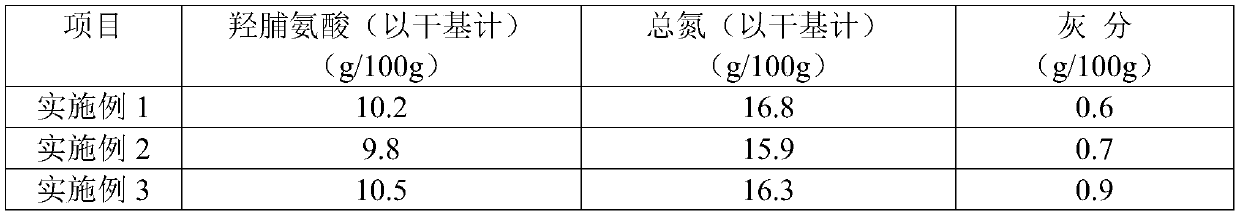

Embodiment 1

[0046] (1) Pre-treatment of raw materials: remove impurities and clean the skin of deep-sea fish (hairtail) and cut them into granules with an average particle size of 1 μm. Soak them in 0.02M NaOH solution 3 times the weight of raw materials at room temperature for 12 hours, and then wash them with clean water. Rinse until the pH value is neutral, then use 0.02M HCl solution 3 times the weight of the raw material to soak at room temperature for 2 hours, then rinse with water until the pH value is neutral, add 4 times the volume of water, and use a colloid mill to prepare coarse Collagen solution.

[0047] (2) Heat treatment: heat the crude collagen solution in hot water at 90° C. for 30 minutes, and then lower the temperature to 50-55° C. to obtain a denatured collagen solution.

[0048] (3) Enzymolysis: Add 0.1% (w / w) high-efficiency compound enzyme preparation of raw material weight to the denatured collagen solution, mix well, and enzymolyze under natural conditions withou...

Embodiment 2

[0054] (1) Raw material pre-treatment: remove impurities and clean the skin of deep-sea fish (salmon), cut it into crumbs with an average particle size of 3 μm, soak it in 0.02M NaOH solution 3.5 times the weight of the raw material at room temperature for 12 hours, and then wash it with clean water Rinse until the pH value is neutral, then use 0.02M HCl solution 3.5 times the weight of the raw material to soak at room temperature for 2 hours, then rinse with water until the pH value is neutral, add 4 times the volume of water, and use a colloid mill to prepare crude Collagen solution.

[0055] (2) Heat treatment: heat the crude collagen solution in hot water at 90° C. for 30 minutes, and then lower the temperature to 50-55° C. to obtain a denatured collagen solution.

[0056] (3) Enzymolysis: Add 0.1% (w / w) high-efficiency compound enzyme preparation of raw material weight to the denatured collagen solution, mix well, and enzymolyze under natural conditions without adjusting ...

Embodiment 3

[0062] (1) Raw material pretreatment: remove impurities and wash the deep-sea fish (cod) skin, cut it into crumbs with an average particle size of 5 μm, soak it in 0.02M NaOH solution 4 times the weight of the raw material at room temperature for 12 hours, and then wash it with clean water Rinse until the pH value is neutral, then use 0.02M HCl solution 4 times the weight of the raw material to soak at room temperature for 2 hours, then rinse with water until the pH value is neutral, add 4 times the volume of water, and use a colloid mill to prepare crude Collagen solution.

[0063] (2) Heat treatment: heat the crude collagen solution in hot water at 90° C. for 30 minutes, and then lower the temperature to 50-55° C. to obtain a denatured collagen solution.

[0064] (3) Enzymolysis: Add 0.1% (w / w) high-efficiency compound enzyme preparation of raw material weight to the denatured collagen solution, mix evenly, and enzymolyze under natural conditions without adjusting the pH val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com