Matt weather-resistant powder coating and preparation method thereof

A technology of powder coating and weather resistance, which is applied in the direction of powder coating, polyester coating, coating, etc., and can solve the problem of poor weather resistance of matte powder coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

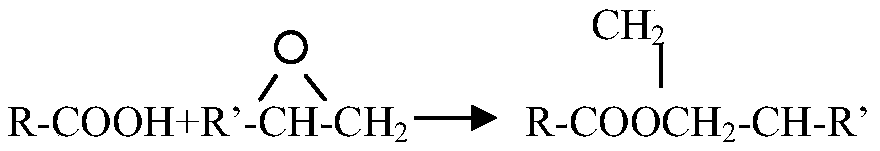

Method used

Image

Examples

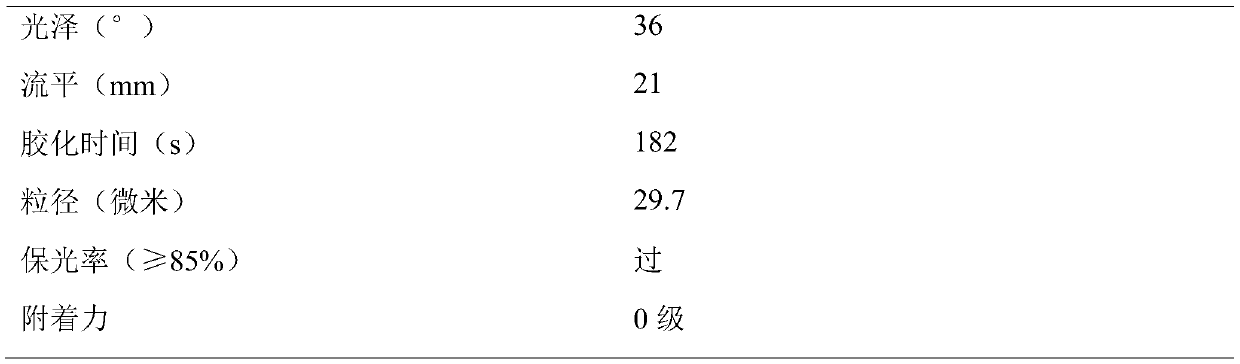

Embodiment 1

[0057] A method for making a matte weather-resistant powder coating in the above technical solution, comprising the following steps:

[0058] Step 1, preparing the first powder:

[0059] 1) Pre-mixing, FEVE (fluoroolefin- Vinyl ether copolymer) 8% thermosetting fluorine powder resin, 2% polyurethane powder coating curing agent or polyisocyanate adduct with Tg glass transition temperature 45-48, 4.6% triglycidyl isocyanurate, acrylate copolymer and Mixture of silicon dioxide 0.8%, copolymer of butyl acrylate and methyl methacrylate 0.5%, benzoin 0.4%, modified amide wax powder 0.5%, barium sulfate 39%, rutile titanium dioxide 1.2%, Mix carbon black, iron oxide red, iron oxide yellow 1.67% evenly;

[0060] 2) Extrusion. Extrude the mixture obtained in 1). The extrusion process uses a Shengshida 60 extruder. The temperature in zone 1 is 90°C±2, the temperature in zone 2 is 95°C±2, and the temperature in zone 3 is 105°C ±2, the temperature in Zone 4 is 100°C±2, the temperature ...

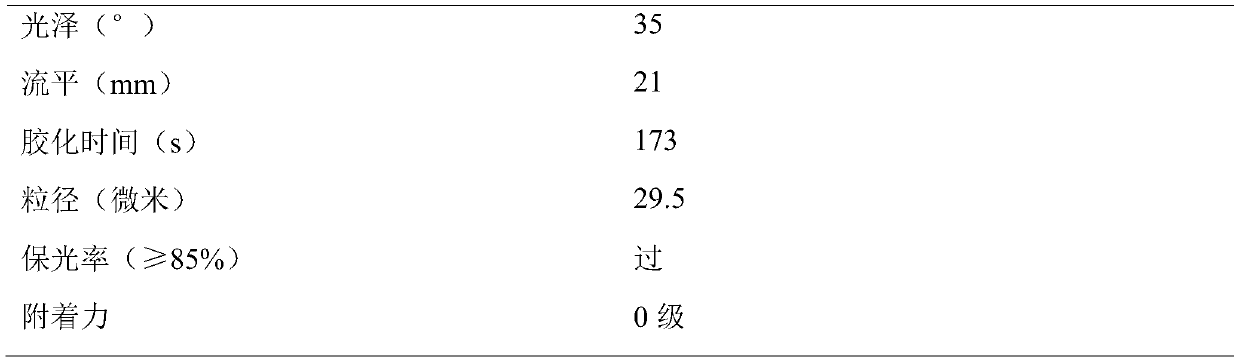

Embodiment 2

[0068] Step 1, preparing the first powder:

[0069] 1) Pre-mixing, 41.4% of the super weather-resistant polyester resin with an acid value of 55-65 mgKOH / g and a viscosity of 0.25-0.4 Pa.S, and FEVE (fluoroolefin-ethylene resin with a Tg glass transition temperature of 51-55) base ether copolymer) thermosetting fluorine powder resin 10%, polyurethane powder coating curing agent or polyisocyanate adduct with Tg glass transition temperature 45-48 2.5%, triglycidyl isocyanurate 4.6%, acrylate copolymer and di Silicon oxide mixture 0.8%, butyl acrylate and methyl methacrylate copolymer 0.5%, benzoin 0.4%, modified amide wax powder 0.5%, barium sulfate 36.5%, rutile titanium dioxide 1.2%, carbon Mix black, iron oxide red, and iron oxide yellow 1.67% evenly; (the name of the specific material will be added in)

[0070] 2) Extrusion. Extrude the mixture obtained in 1). The extrusion process uses a Shengshida 60 extruder. The temperature in zone 1 is 90°C±2, the temperature in zone 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com