Composite woody oil fat emulsion preparation with invigorating stomach function and its preparation method and application

A technology of emulsion preparation and wood balsam, which is applied in the directions of oil/fat/wax inactive ingredients, medical preparations containing active ingredients, and pharmaceutical formulations, etc. , the effect of excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1 compound woody oil fat emulsion injection preparation one

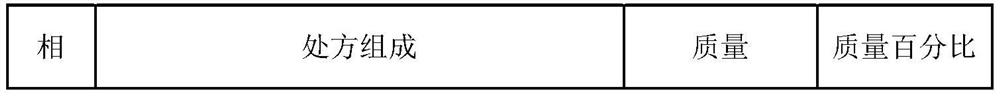

[0059] (1) Composition is as shown in table 1:

[0060] Table 1

[0061]

[0062]

[0063] (2) Preparation method

[0064] 1) Add 45g of wheat germ oil (both for injection) to 40g of corn germ oil in a water bath at about 55°C and nitrogen protection, mix well, then add 15g of woody oil, stir well, add 20g of soybean lecithin and 100mg of vitamin E. Stir until the phospholipid dissolves to form a uniform mixed phase, and cool to room temperature to obtain an oil phase.

[0065] 2) Put 800mL of water for injection in a container under the protection of a water bath at about 55°C and nitrogen, add 40g of povidone, 22g of glycerin for injection and 15g of soybean lecithin, shear and stir to dissolve and mix evenly, and cool to room temperature to obtain an aqueous phase.

[0066] 3) Under stirring conditions, slowly add the oil phase to the water phase, while shearing and stirring for about ...

Embodiment 2

[0070] Example 2 Composite woody oil fat emulsion injection preparation two

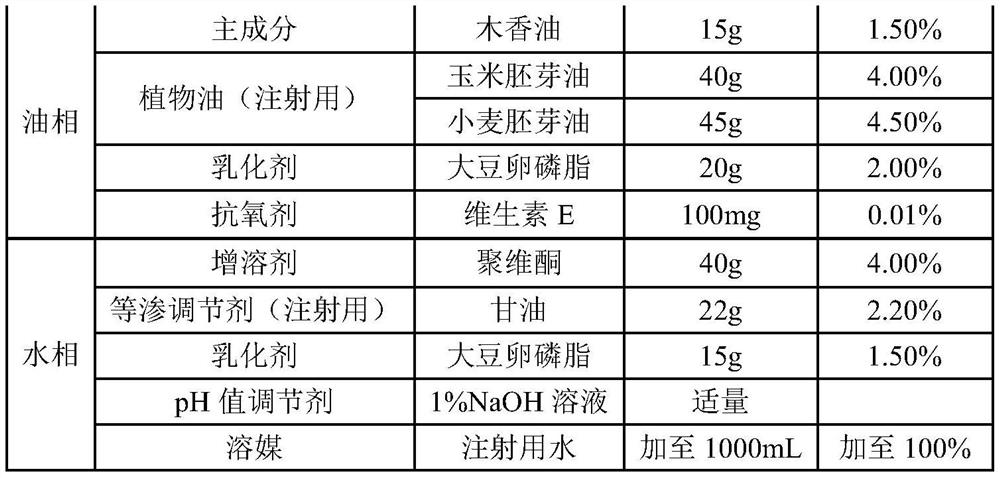

[0071] (1) Composition is as shown in table 2:

[0072] Table 2

[0073]

[0074]

[0075] (2) Preparation method

[0076] 1) Add 35g of wheat germ oil (both for injection) to 50g of coix seed oil in a water bath at about 56°C and nitrogen protection, mix well, then add 15g of woody oil, stir until uniform, add 20g of egg yolk lecithin and 100mg Vitamin C, stirred until the phospholipids dissolve to form a uniform mixed phase, cooled to room temperature to obtain an oil phase.

[0077] 2) Put 800mL of water for injection in a container at about 56°C under nitrogen protection, add 30g of polyethylene glycol, 22g of glycerin for injection and 15g of egg yolk lecithin, shear and stir to dissolve and mix evenly, and cool to room temperature to obtain an aqueous phase.

[0078] 3) Under stirring conditions, slowly add the oil phase to the water phase, while shearing and stirring for about 20 min...

Embodiment 3

[0082] Example 3 Composite woody oil fat emulsion injection preparation three

[0083] (1) Composition is as shown in table 3:

[0084] table 3

[0085]

[0086]

[0087] (2) Preparation method

[0088] 1) In a water bath at about 58°C and under nitrogen protection, add 20g of royal rice oil and 25g of wheat germ oil (both for injection) to 35g of coix seed oil, mix well, then add 20g of wood fragrance oil, stir until uniform, and put in 20g Egg yolk lecithin and 100 mg of vitamin E were stirred until the phospholipids were dissolved to form a uniform mixed phase, cooled to room temperature to obtain an oil phase.

[0089] 2) Put 800mL of water for injection in a container under the protection of a water bath at about 58°C and nitrogen, add 25g of povidone, 22g of glycerin for injection and 15g of egg yolk lecithin, shear and stir to dissolve and mix evenly, and cool to room temperature to obtain an aqueous phase.

[0090] 3) Under stirring conditions, slowly add the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com