Preparation method of composite bone tissue engineering stent material

A technology of bone tissue engineering and scaffold material, which is applied in the field of bone tissue engineering in the medical field and the preparation of chitosan/silk fibroin/hydroxyapatite bone tissue engineering scaffold material, can solve the problem of mild reaction conditions of the preparation method and scaffold material. Unable to meet the requirements and other problems, to achieve the effect of mild reaction conditions, inhibition of bone resorption process, and enhancement of ALP activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

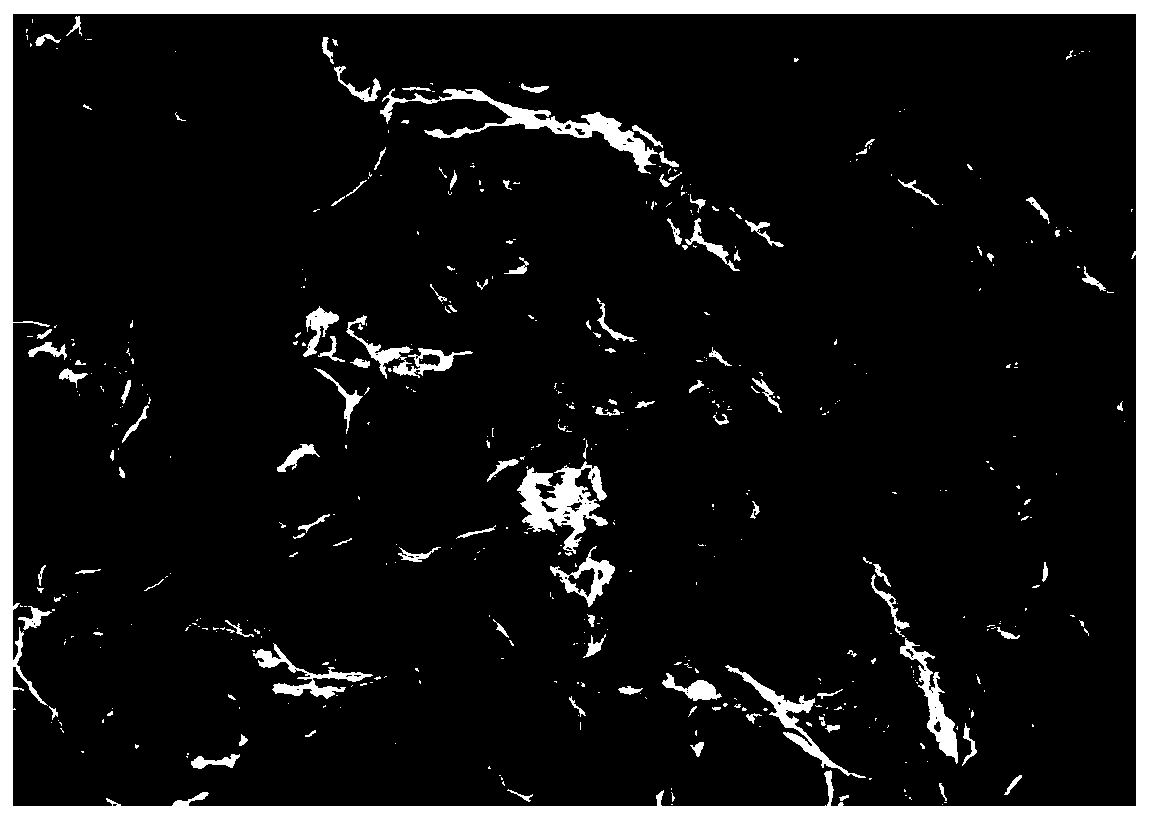

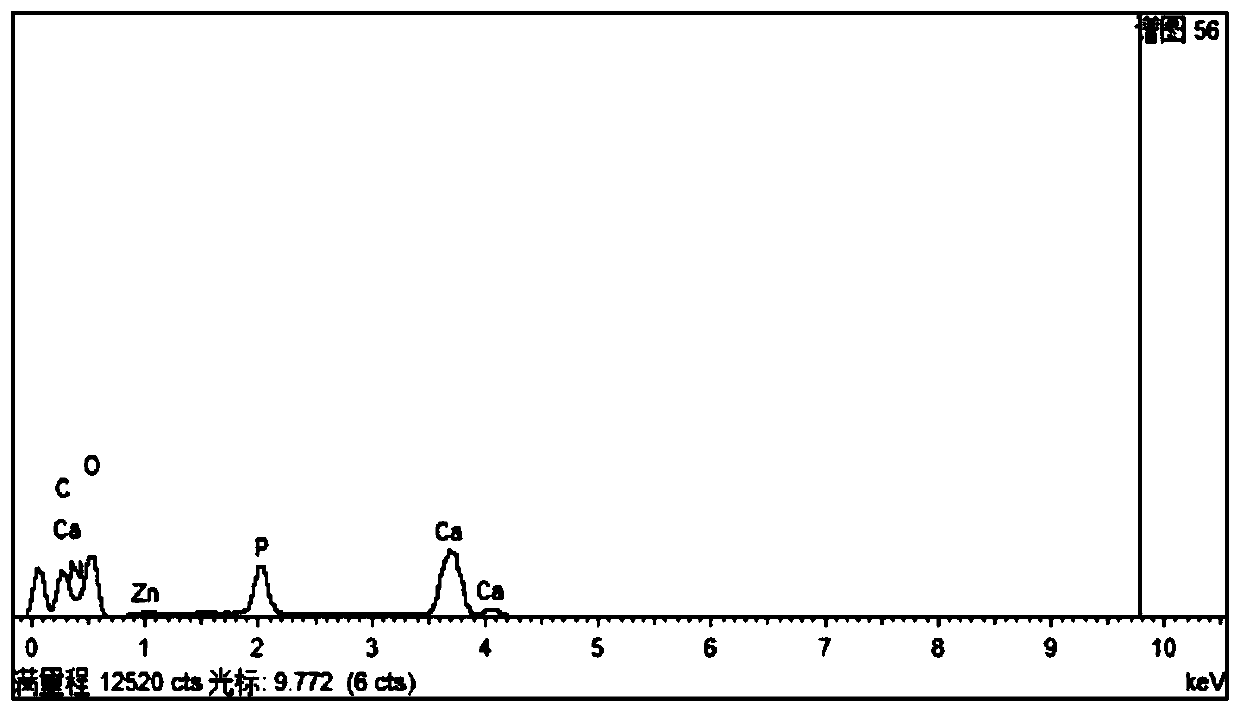

Image

Examples

Embodiment 1

[0029] A preparation method for a composite bone tissue engineering scaffold material, comprising the steps of:

[0030] Step 1), the preparation of the hydroxyapatite of zinc ion sustained release:

[0031] Get 0.2109 grams of calcium chloride and 0.0136 grams of zinc chloride and dissolve them in 25 milliliters of deionized water, slowly add 15 milliliters of creatine phosphate solution with a mass concentration of 2.5% at a rate of 40-60 drops / min, stir and mix Evenly, microwave at 100 degrees, heat for 10 minutes, stir at room temperature at 150-220r / min for 2-3h, adjust the pH of the reaction solution to 9-10 after stirring, sink in a water bath at the reaction temperature for 24-48h, and vacuum filter. Rinse three times with deionized water to obtain zinc ion slow-release hydroxyapatite;

[0032] Step 2), adding the zinc ion slow-release hydroxyapatite obtained in step 1) into the chitosan solution, stirring and mixing evenly and adjusting the pH value to 8.0 to obtain ...

Embodiment 2

[0038] A preparation method for a composite bone tissue engineering scaffold material, comprising the steps of:

[0039] Step 1), the preparation of the hydroxyapatite of zinc ion sustained release:

[0040] Dissolve 0.1 gram of calcium chloride and 0.01 gram of zinc chloride in 20 milliliters of deionized water, slowly add 10 milliliters of creatine phosphate solution with a mass concentration of 2.5% at a rate of 40 drops / min, stir and mix evenly during the period, Microwave at 100 degrees, heat for 10 minutes, stir at room temperature at 150-220r / min for 2 hours, adjust the pH value of the reaction solution to 9-10 after stirring, sink in a water bath at the reaction temperature for 24-48 hours, vacuum filter, and use deionized water Rinse three times to obtain zinc ion slow-release hydroxyapatite;

[0041] Step 2), adding the zinc ion slow-release hydroxyapatite obtained in step 1) into the chitosan solution, stirring and mixing evenly and adjusting the pH value to 8.0 to...

Embodiment 3

[0046] A preparation method for a composite bone tissue engineering scaffold material, comprising the steps of:

[0047] Step 1), the preparation of the hydroxyapatite of zinc ion sustained release:

[0048] Get 0.5 grams of calcium chloride and 0.03 grams of zinc chloride and dissolve them in 30 milliliters of deionized water, slowly add 20 milliliters of creatine phosphate solution with a mass concentration of 2.5% at a rate of 60 drops / min, stir and mix evenly during the period, Microwave at 100 degrees, heat for 10 minutes, stir at room temperature at 150-220r / min for 3 hours, adjust the pH of the reaction solution to 9-10 after stirring, sink in a water bath at the reaction temperature for 24-48 hours, vacuum filter, and use deionized water Rinse three times to obtain zinc ion slow-release hydroxyapatite;

[0049] Step 2), adding the zinc ion slow-release hydroxyapatite obtained in step 1) into the chitosan solution, stirring and mixing evenly and adjusting the pH value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com