CsPbX3@TiO2 nanomaterial as well as preparation method and application thereof

A nano-material and reaction technology, applied in the field of CsPbX3@TiO2 nano-materials, can solve the problems of poor water stability, limitation, and complicated traditional methods, and achieve the effect of uniform coating, simple operation, and obvious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

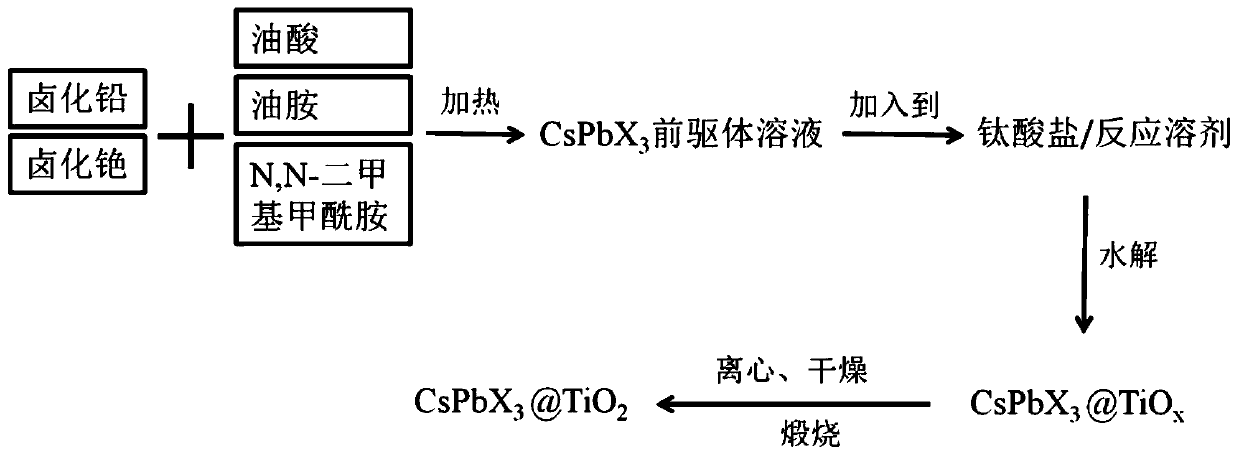

[0049] (1) CsPbBr 3 Preparation of precursor solution: Weigh cesium bromide:lead bromide molar mass ratio of 0.5mmol:0.5mmol, in a 25mL three-necked flask, add a mixture of oleic acid:oleylamine volume ratio of 0.5mL:0.5mL, then, Add 10mL N,N-dimethylformamide (DMF), heat to 100°C under the protection of argon, and react for 3 hours to obtain CsPbBr with clear color 3 Precursor solution;

[0050] (2) CsPbBr 3 @TiO x Preparation: take 0.3mL of CsPbBr prepared in step (1) 3 Precursor solution, at a speed of 1200rpm, quickly add it to 10mL of n-hexane that has been dried after dehydration, and after stirring for 15 minutes, add 1mL of a n-hexane solution of tetrabutyl titanate with a concentration of 20mg / mL dropwise, and after 30s, turn to Adjusted back to 150rpm, by sol-gel method in CsPbBr 3 Surface hydrolysis coated TiO x , continue to stir the reaction for 2 hours, and centrifuge at 5000rpm for 10 minutes to obtain CsPbBr 3 @TiO x precipitation;

[0051] (3) CsPbBr ...

Embodiment 2

[0053] (1) CsPbCl 3 Preparation of precursor solution: Weigh cesium chloride: lead chloride molar mass ratio of 1mmol: 1mmol, in a 25mL three-necked flask, add a mixture of oleic acid: oleylamine volume ratio of 1.0mL: 0.5mL, and then add 10mL N,N-Dimethylformamide (DMF), heated to 100°C under the protection of argon, and reacted for 3 hours to obtain CsPbCl with clear color 3 Precursor solution;

[0054] (2) CsPbCl 3 @TiO x Preparation: Take 0.5mL of the precursor solution prepared in step (1), and quickly add it to 10mL of n-hexane that has been dehydrated and dried at a rotating speed of 1200rpm. After stirring for 30 minutes, add dropwise 1mL of 40mg / mL Titanium tetrachloride / n-hexane solution, the rotation speed was adjusted back to 150rpm after 30s, and the CsPbCl 3 Surface hydrolysis coated TiO x , continue to stir the reaction for 3 hours, and centrifuge at 5000rpm for 20 minutes to obtain CsPbCl 3 @TiO x precipitation;

[0055] (3) CsPbCl 3 @TiO 2 The prepar...

Embodiment 3

[0057] (1) CsPbI 3 Preparation of precursor solution: Weigh cesium iodide: lead iodide molar mass ratio of 1mmol: 1mmol, in a 25mL three-necked flask, add a mixture of oleic acid: oleylamine volume ratio of 0.5mL: 1mL, then add 10mLN, N-dimethylformamide (DMF), heated to 120°C under the protection of argon, and reacted for 2 hours, the clear color CsPbI can be obtained 3 Precursor solution;

[0058] (2) CsPbI 3 @TiO x Preparation: Take 0.4mL of the precursor solution prepared in step (1), quickly add it into 10mL of toluene that has been dehydrated and dried at a rotational speed of 1200rpm, stir for 30 minutes, and then add 1mL of titanium with a concentration of 50mg / mL dropwise. Acetyl tetrabutyl ester / toluene solution, after 30s, the rotation speed was adjusted back to 150rpm, and the CsPbI 3 Surface hydrolysis coated TiO x , continue to stir the reaction for 3 hours, and centrifuge at 5000rpm for 10 minutes to obtain CsPbI 3 @TiO x precipitation;

[0059] (3) CsPb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com