Corrosion-resistant navigation mark and processing method thereof

A corrosion-resistant and corrosion-resistant coating technology, applied in the field of navigation marks, can solve the problems of limited corrosion resistance, high maintenance costs, and short service life, and achieve the effects of short service life, high maintenance costs, and convenient use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

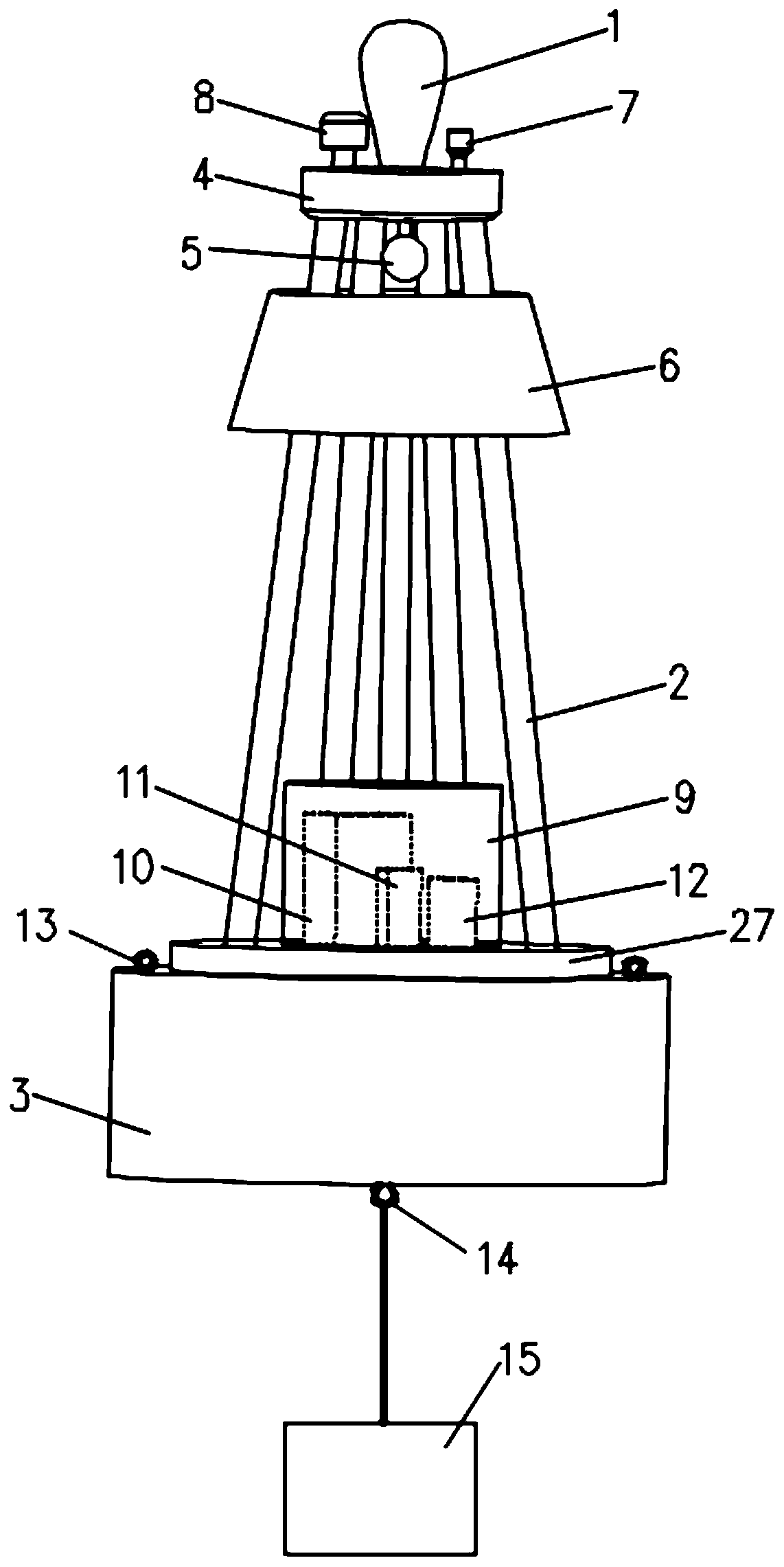

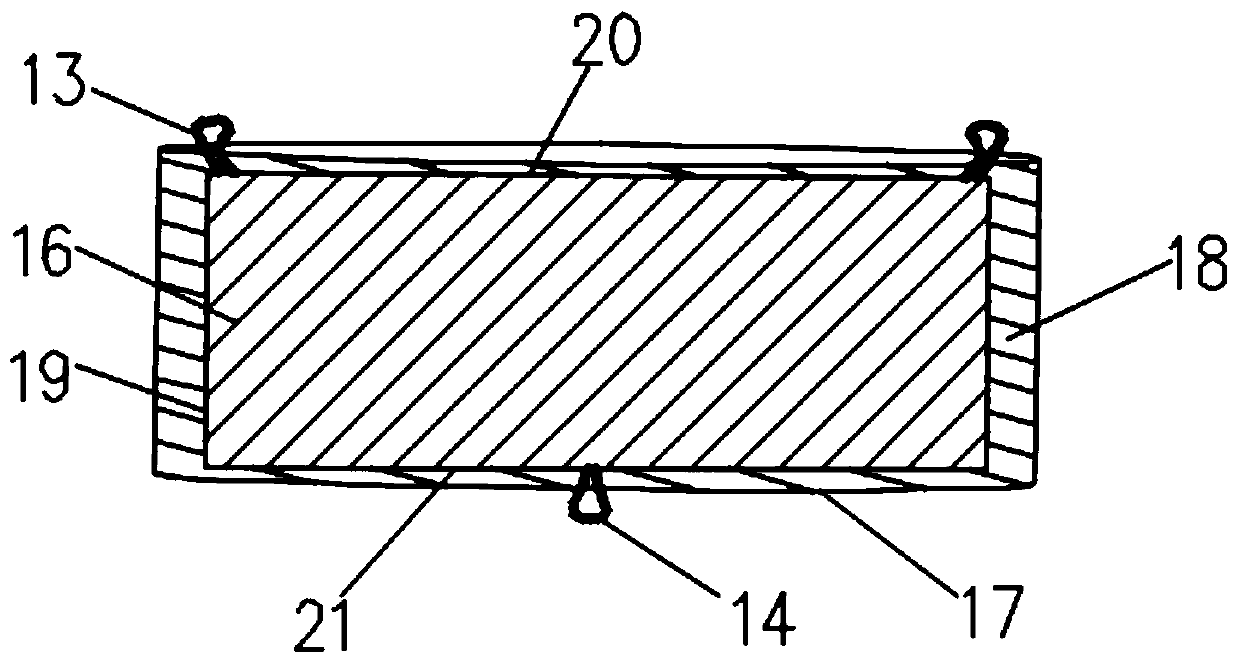

[0042] as attached figure 1 As shown, a corrosion-resistant buoy includes a buoy light 1, a bracket 2, and a buoy 3, and is equipped with a positioning anchor 15. The outer surface of the buoy is provided with a corrosion-resistant coating, and the upper end of the bracket 2 is fixed with a An observation platform 4, the navigation beacon light 1 is arranged on the observation platform 4, a bottom plate 27 is provided at the lower end of the support 2, and the bottom plate 27 and the floating body 3 are fixedly connected by bolts, and the floating body 3 and the floating body 3 are connected by bolts. The positioning anchors 15 are connected by a chain.

[0043] The weight ratio of the positioning anchor 15 to the buoy as a whole is 2:1-5:2, the positioning anchor 15 includes a box body, the box body is cast iron, and reinforced concrete is poured into the box body, and the reinforced concrete includes steel Fiber and polyvinyl alcohol fiber, according to the percentage of co...

Embodiment 2

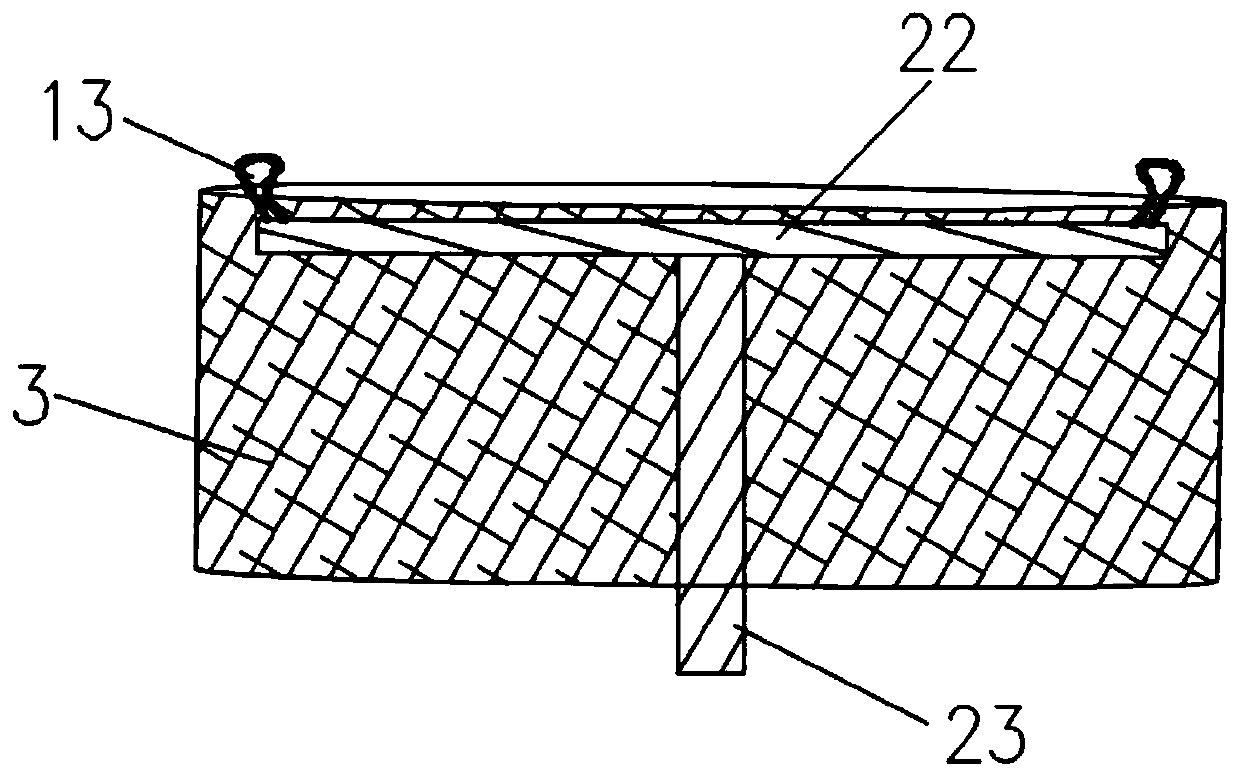

[0059] Based on the above-mentioned embodiment 1, the similarities will not be repeated, and the difference is that, as attached image 3 As shown, the floating body 3 includes a connecting plate 22 and a connecting rod 23. The connecting plate 22 is provided with two lifting rings 13 by welding. The lifting rings 13 pass through the outer surface of the floating body 3. The connecting plate 22 is fixedly connected with the connecting rod 23. The surface is made of polyurea material, the thickness is 15-20 mm, and the floating body 3 is filled with low-density polyethylene without gaps.

[0060] The lower end of the connecting rod 23 is connected with the positioning anchor 15 by a connecting device, as attached Figure 4 As shown, the connection device is a rotatable structure, including a ball head 24, a sleeve rod 25 and a protective cover 26, the tail end of the ball head 24 is embedded and fixed at the lower end of the connecting rod 23, and the top of the ball head 24 is...

Embodiment 3

[0063] Based on above-mentioned embodiment 1, a kind of processing method of corrosion-resistant navigation mark, comprises the following steps:

[0064] S1, prepare steel material by casting and smelting process, adopt steel material to prepare support 2, observation platform 4 and base plate 27, support 2 is welded by seamless steel pipe, then spray resistant on the outer surface of support 2, observation platform 4 and base plate 27 Corrosion coatings, wherein the corrosion-resistant coatings include (by weight): 20-35 parts of epoxy resin, 12-25 parts of polyester, 1-4 parts of titanate coupling agent, 5-15 parts of graphene, zinc powder 10-25 parts, 30-45 parts of siloxane oligomer, 3-15 parts of antimicrobial agent, and the thickness of corrosion-resistant coating is 30-50g / m 2 , preferably 35-45g / m 2 , and after high-temperature drying treatment, the temperature is 100-180 ° C, and the treatment time is 20-40 minutes;

[0065] S2. Fix the observation platform 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com