Treatment method for nitric acid type high-chlorine ammonia-nitrogen-containing wastewater

A technology of ammonia nitrogen wastewater and treatment method, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. , handle the effect of mild environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

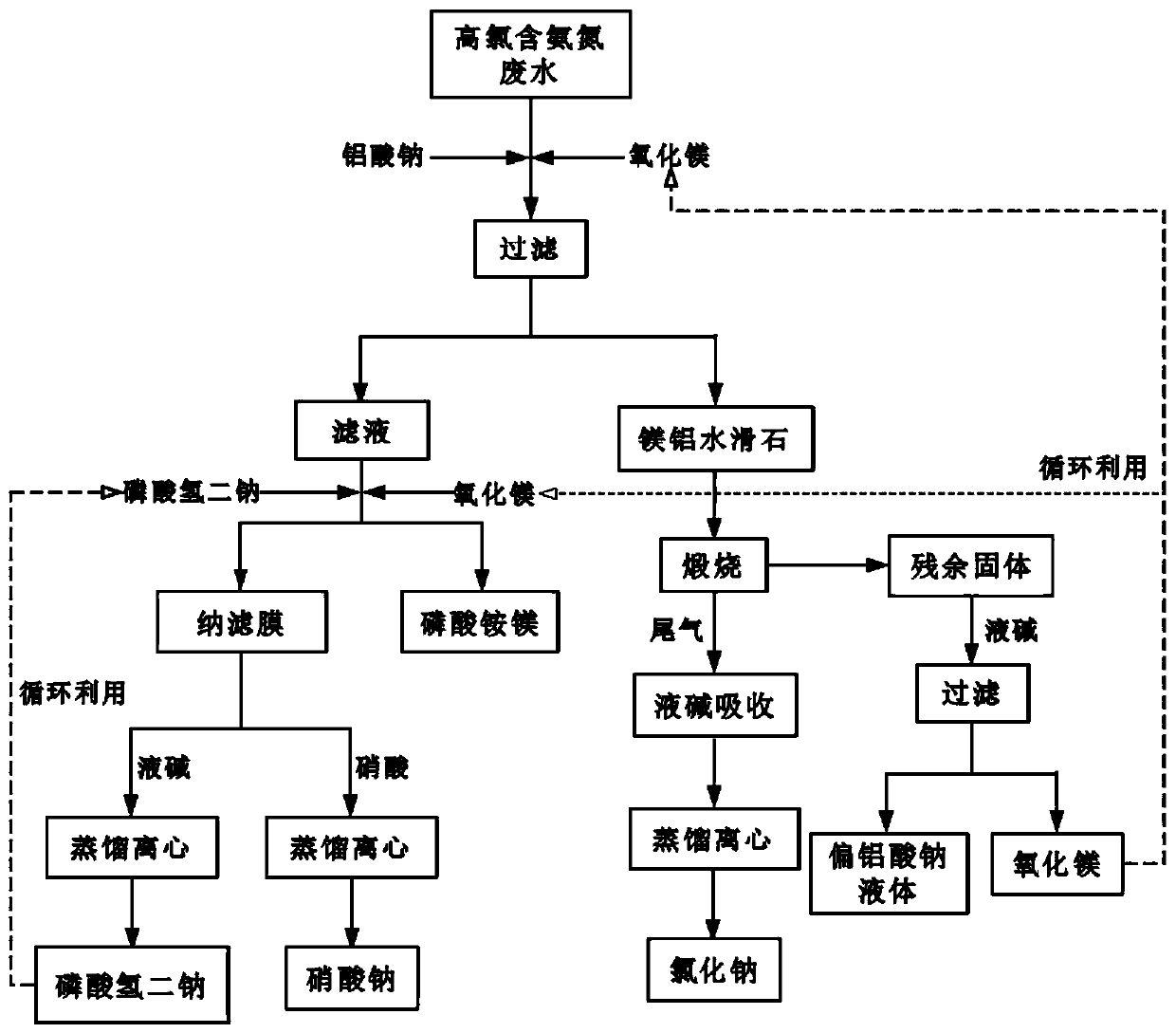

Image

Examples

Embodiment 1

[0029] Take 1 ton of chlorine-containing wastewater, use 30wt% liquid caustic soda to adjust pH=9, add magnesium oxide and sodium aluminate at the same time according to the mass concentration ratio of chlorine in wastewater as 2:2:1, and stir and react for 2 hours at 40°C Filtration and separation to obtain aluminum magnesium hydrotalcite solid and filtrate, the determination of chlorine content in the filtrate is 4.32ppm;

[0030] Add magnesium oxide and disodium hydrogen phosphate in sequence to the above filtrate according to the mass concentration ratio of ammonia nitrogen in the wastewater 1.2:1.1:1, stir for 1 hour and then filter and separate. The ammonia nitrogen content in the filtrate is reduced to 6.83ppm. Dry for 6 hours to obtain white magnesium ammonium phosphate crystals, which can be used as medicine and fertilizer;

[0031] Pass the filtrate into the nanofiltration membrane system to obtain two kinds of dope, respectively use mass concentration of 30% liquid ...

Embodiment 2

[0034] Take 1.5 tons of chlorine-containing wastewater, use a liquid caustic soda with a mass concentration of 35wt% to adjust the pH=9.5, and add magnesium oxide and sodium aluminate at the same time according to the mass concentration ratio of chlorine in the wastewater to 2.5:2:1, and stir and react at 45°C for 2.5h After filtering and separating to obtain the aluminum-magnesium hydrotalcite solid and the filtrate, the chlorine content in the filtrate was determined to be 3.68ppm;

[0035] Magnesium oxide and disodium hydrogen phosphate were sequentially added to the above filtrate according to the mass concentration ratio of ammonia nitrogen in the waste water at 1.25:1.1:1, stirred for 1.5 hours, filtered and separated, the ammonia nitrogen content in the filtrate was reduced to 2.69ppm, and the solid precipitate was heated at 56°C Drying at low temperature for 7 hours to obtain white magnesium ammonium phosphate crystals, which can be used as medicine and fertilizer;

[...

Embodiment 3

[0039] Take 2 tons of chlorine-containing wastewater, use a mass concentration of 40wt% liquid caustic soda to adjust pH=10, add magnesium oxide and sodium aluminate at the same time according to the mass concentration ratio of chlorine in the wastewater to 3:2:1, and stir and react for 3 hours at 50°C Filtration and separation to obtain aluminum magnesium hydrotalcite solid and filtrate, the determination of chlorine content in the filtrate is 1.98ppm;

[0040] Magnesium oxide and disodium hydrogen phosphate were sequentially added to the above filtrate according to the mass concentration ratio of ammonia nitrogen in the waste water at 1.5:1.1:1, stirred for 2 hours, filtered and separated, the ammonia nitrogen content in the filtrate was reduced to 4.36ppm, and the solid precipitate was heated at 60°C Dry for 8 hours to obtain white magnesium ammonium phosphate crystals, which can be used as medicine and fertilizer;

[0041] Pass the filtrate into the nanofiltration membrane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com