Graphite phase carbon nitride modified antimony doped tin dioxide composite photoelectric catalysis electrode and preparation method and applications thereof

A technology of graphite phase carbon nitride and tin dioxide, applied in chemical instruments and methods, oxidized water/sewage treatment, light water/sewage treatment, etc., can solve the problem of low photocatalytic efficiency of antimony-doped tin dioxide electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

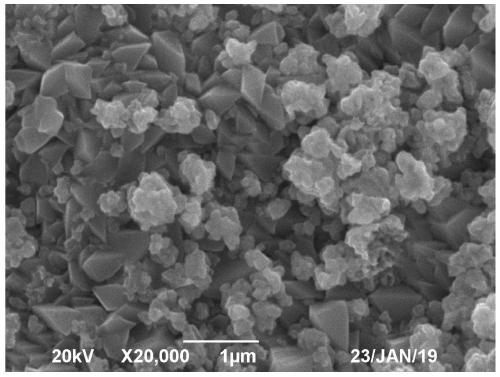

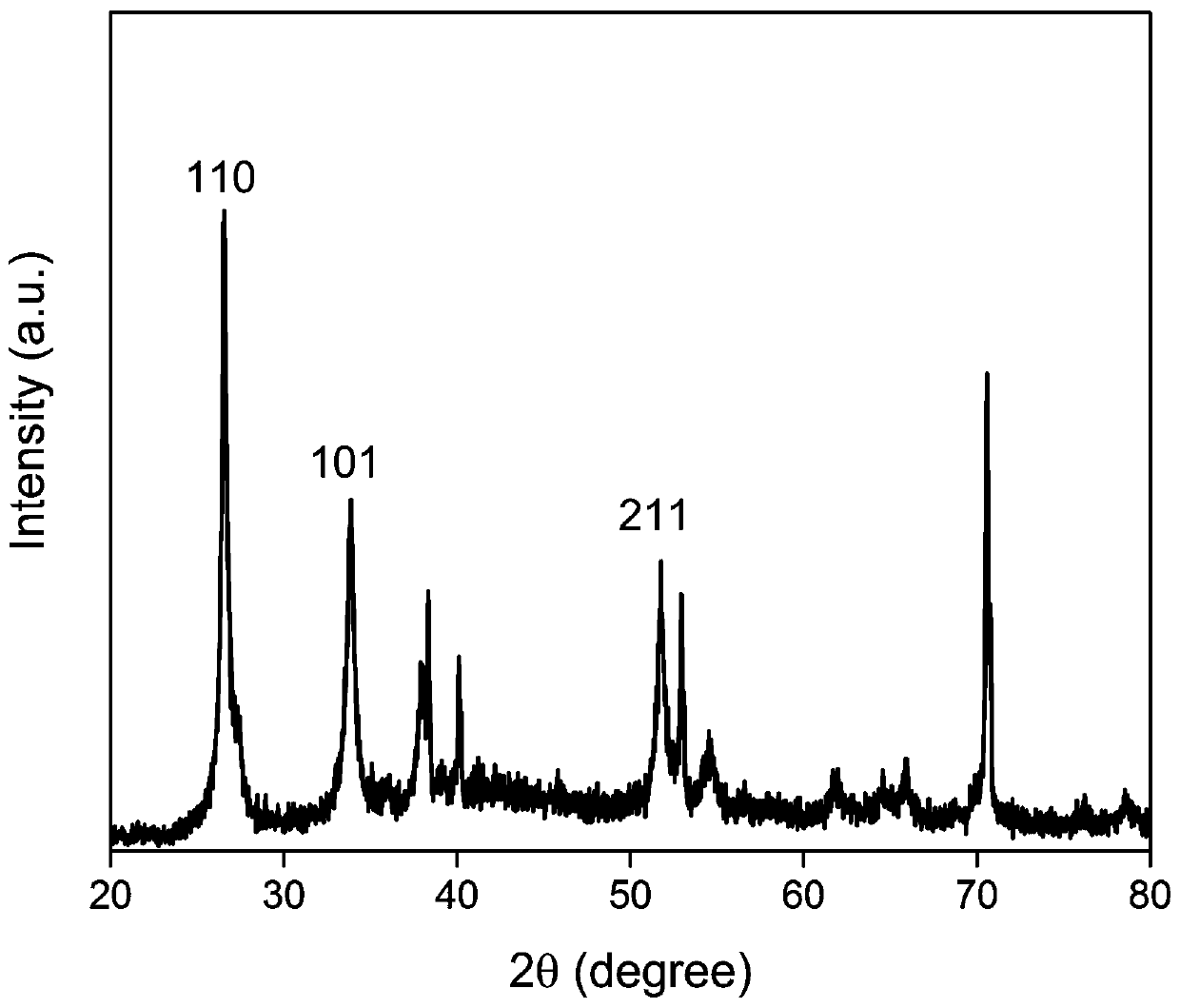

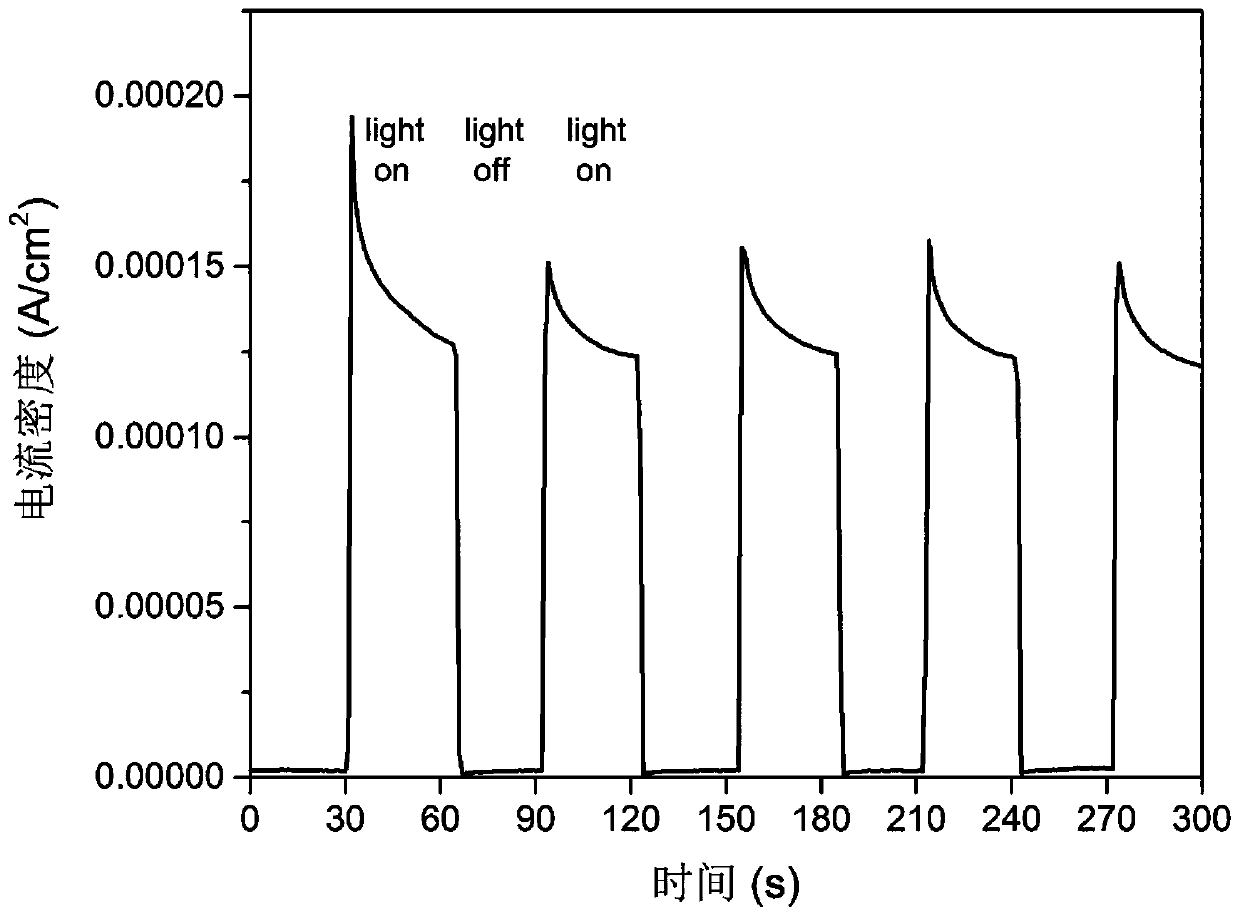

[0032] In this example, the preparation method of the antimony-doped tin dioxide photoelectrocatalytic composite electrode modified by graphite phase carbon nitride is as follows:

[0033] The titanium plate was cut into a size of 2.0cm×2.0cm, polished with 400-mesh, 800-mesh, and 1200-mesh sandpaper in sequence, and degreased in 10wt% sodium hydroxide solution for 1h; then heated and etched in 10wt% oxalic acid solution for 2h; finally Rinse well and store in ultrapure water for later use.

[0034] Weigh 20g of melamine in a crucible and calcinate at 550°C for 3h to obtain bulk graphite phase carbon nitride; take it out and grind it in a mortar, pass through a 400-mesh sieve, and sonicate in acetone at a mass-volume ratio of 1g:40mL Peel off for 3h to obtain graphitic carbon nitride;

[0035] The sol-gel precursor is prepared according to the molar ratio of citric acid: ethylene glycol: tin tetrachloride pentahydrate: antimony trichloride: graphite phase carbon nitride is 13...

Embodiment 2

[0038] In this example, the preparation method of the antimony-doped tin dioxide photoelectrocatalytic composite electrode modified by graphite phase carbon nitride is as follows:

[0039] The titanium plate was cut into a size of 2.0cm×2.0cm, polished with 400-mesh, 800-mesh, and 1200-mesh sandpaper in sequence, and degreased in 10wt% sodium hydroxide solution for 1h; then heated and etched in 10wt% oxalic acid solution for 2h; finally Rinse well and store in ultrapure water for later use.

[0040] Weigh 20g of melamine in a crucible and calcinate at 550°C for 3h to obtain bulk graphite phase carbon nitride; take it out and grind it in a mortar, pass through a 400-mesh sieve, and then (1g: 40mL) ultrasonically peel it in acetone for 3h, Obtain graphite phase carbon nitride;

[0041] The sol-gel precursor is prepared according to the molar ratio of citric acid: ethylene glycol: tin tetrachloride pentahydrate: antimony trichloride: graphite phase carbon nitride is 130:30:9:1:2...

Embodiment 3

[0044] In this example, the preparation method of the antimony-doped tin dioxide photoelectrocatalytic composite electrode modified by graphite phase carbon nitride is as follows:

[0045] The titanium plate was cut into a size of 2.0cm×2.0cm, polished with 400-mesh, 800-mesh, and 1200-mesh sandpaper in sequence, and degreased in 10wt% sodium hydroxide solution for 1h; then heated and etched in 10wt% oxalic acid solution for 2h; finally After rinsing, put it into ultrapure water and save it for later use.

[0046] Weigh 20g of melamine in a crucible and calcinate at 550°C for 3h to obtain bulk graphite phase carbon nitride; take it out and grind it in a mortar, pass through a 400-mesh sieve, and then (1g: 40mL) ultrasonically peel it in acetone for 3h, Obtain graphite phase carbon nitride;

[0047] The sol-gel precursor is prepared according to the molar ratio of citric acid: ethylene glycol: tin tetrachloride pentahydrate: antimony trichloride: graphite phase carbon nitride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com