Two-dimensional ultrathin nanosheet graphite phase carbon nitride material rich in nanopores, and preparation method and applications thereof

A graphitic carbon nitride, nanopore technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problem of low photocatalytic efficiency, and achieve the effect of high separation efficiency, simple process flow, and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1). Dissolve 5g of melamine and 0.05g of polyethylene glycol (with a relative molecular weight of about 10,000) in 30mL of deionized water, stir and evaporate the water at 80°C, and then continue to dry for 12 hours to obtain the precursor;

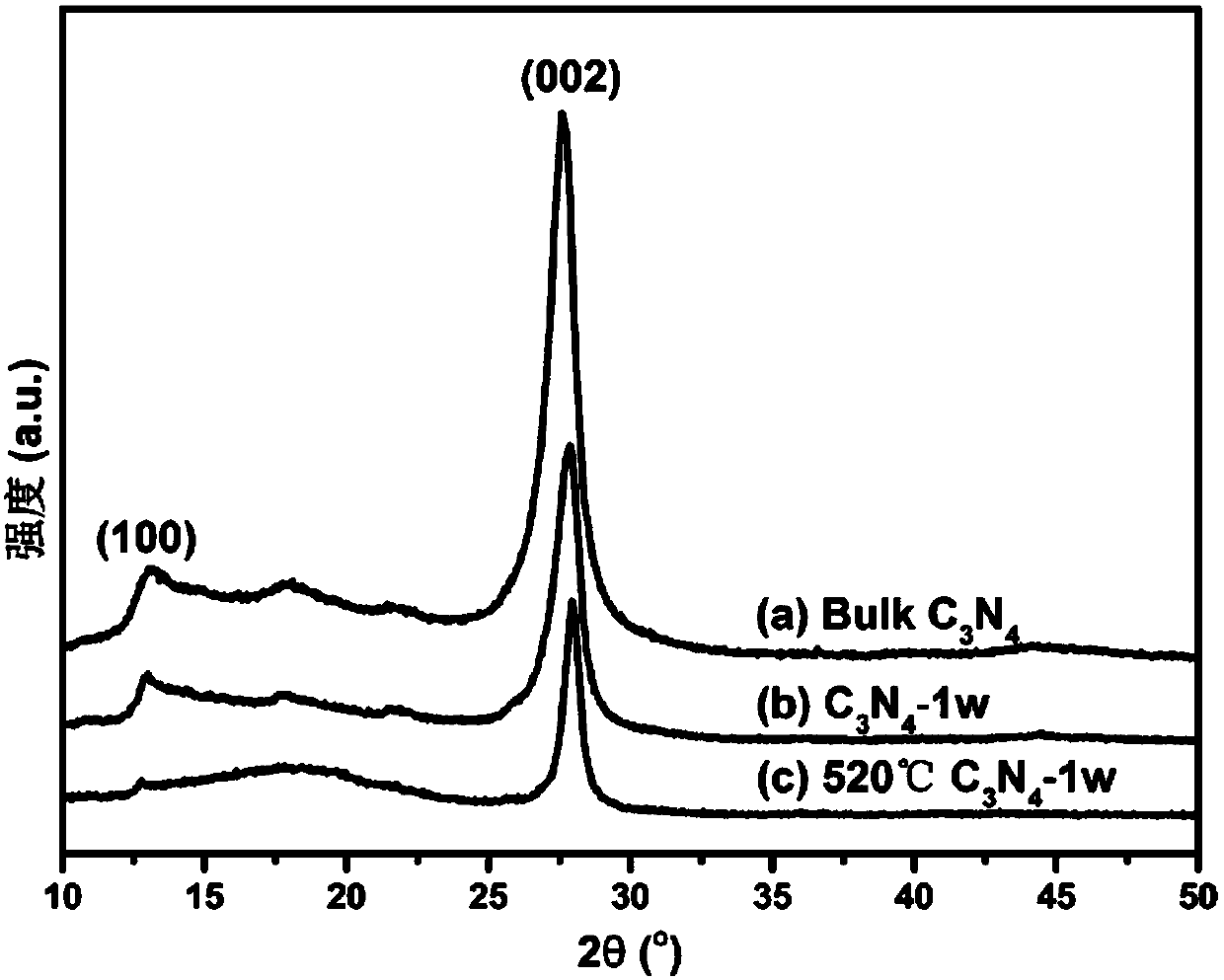

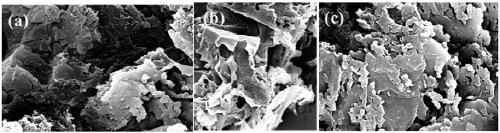

[0039] 2). After grinding the precursor obtained in step 1), place it in a closed crucible and put it into a muffle furnace for sintering at 600°C in an air atmosphere at a heating rate of 5°C / min and holding for 2 hours to obtain agglomerated g-C 3 N 4 Nanosheets;

[0040] 3). The g-C agglomerated in step 2) 3 N 4 After the nano flakes are ground into powder particles, take a certain amount into the corundum crucible, place it in the open crucible and put it into the muffle furnace again and sinter at 520℃ in air atmosphere, the heating rate is 2℃ / min, and the heat preservation is 6 hours to obtain the porous GC 3 N 4 Nanosheet 1.

Embodiment 2

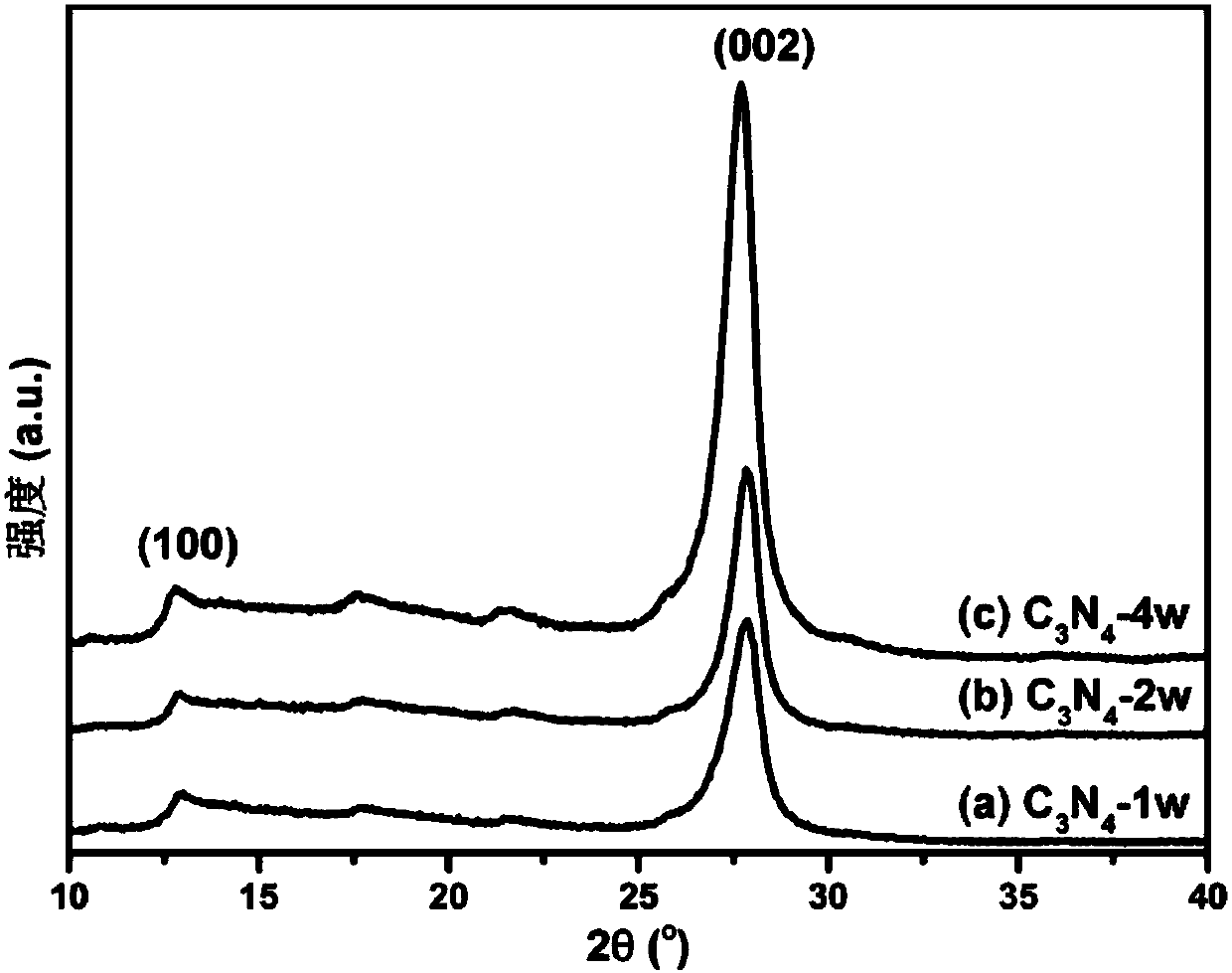

[0042] The difference from Example 1 is that the molecular weight of the polyethylene glycol used is adjusted in step (1). There are two sets of experiments, the first group: polyethylene glycol (relative molecular mass is about 20,000); the second group: polyethylene glycol (relative molecular mass is about 40,000).

Embodiment 3

[0044] The difference from Example 1 is that in step (3), the sintering temperature is adjusted in the muffle furnace under air atmosphere. There are five groups of experiments, the first group: the muffle furnace is sintered at 500°C in air atmosphere; the second group: the muffle furnace is sintered at 540°C in air atmosphere; the third group: the muffle furnace is sintered in air atmosphere at 560°C; The fourth group: the muffle furnace is sintered at 580°C in an air atmosphere; the fifth group: the muffle furnace is sintered at 600°C in an air atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com