Preparation method of novel composite flat plate electric heating film

An electric heating film and flat plate technology, applied in electric heating devices, ohmic resistance heating, ohmic resistance heating parts, etc., can solve the problems of poor environmental stability of metal wire electric heating film and easy oxidation, and harsh production environment of tin oxide electric heating film, etc. The thickness is easy to control, the bonding force is enhanced, and the power can be adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

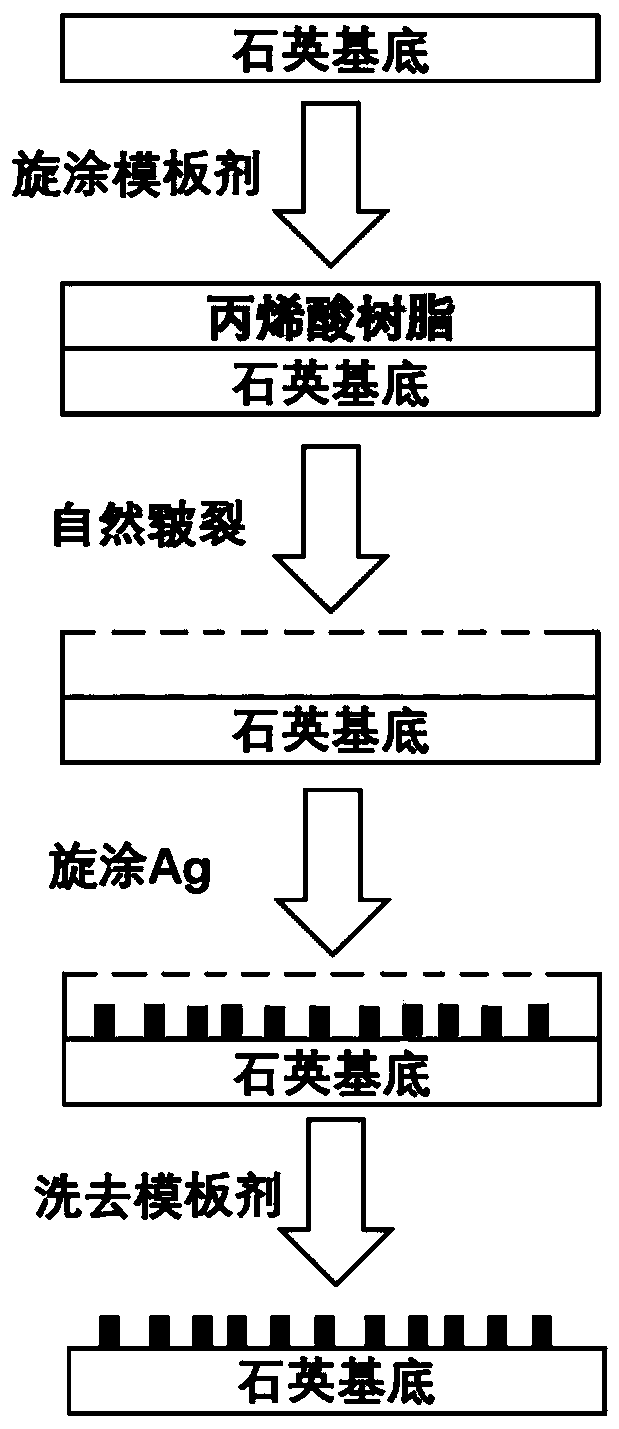

[0034] Embodiment 1: template method prepares the conductive film of silver nanoparticle

[0035] Step 1, disperse commercially available silver nanoparticles in deionized water to form 0.01 mg.mL -1solution as a precursor solution; Step 2, dissolving acrylic resin in a diluent to prepare a 0.4g / mL template; Step 3, dripping the template prepared in Step 2 onto the quartz substrate, and using a rotary The coating method is applied evenly, and then dried in the air to naturally form a cracked template network; step 4, the precursor liquid is added to the substrate on which the template has been formed, and the spin coating method is used to coat evenly, and an oven at a certain temperature Dry in medium, and clean the template agent with chloroform; step 5, glue copper electrode strips on both ends of the prepared electric heating film semi-finished product with silver glue to form an electric heating film device.

[0036] The conductive film of the prepared silver nanoparticl...

Embodiment 2

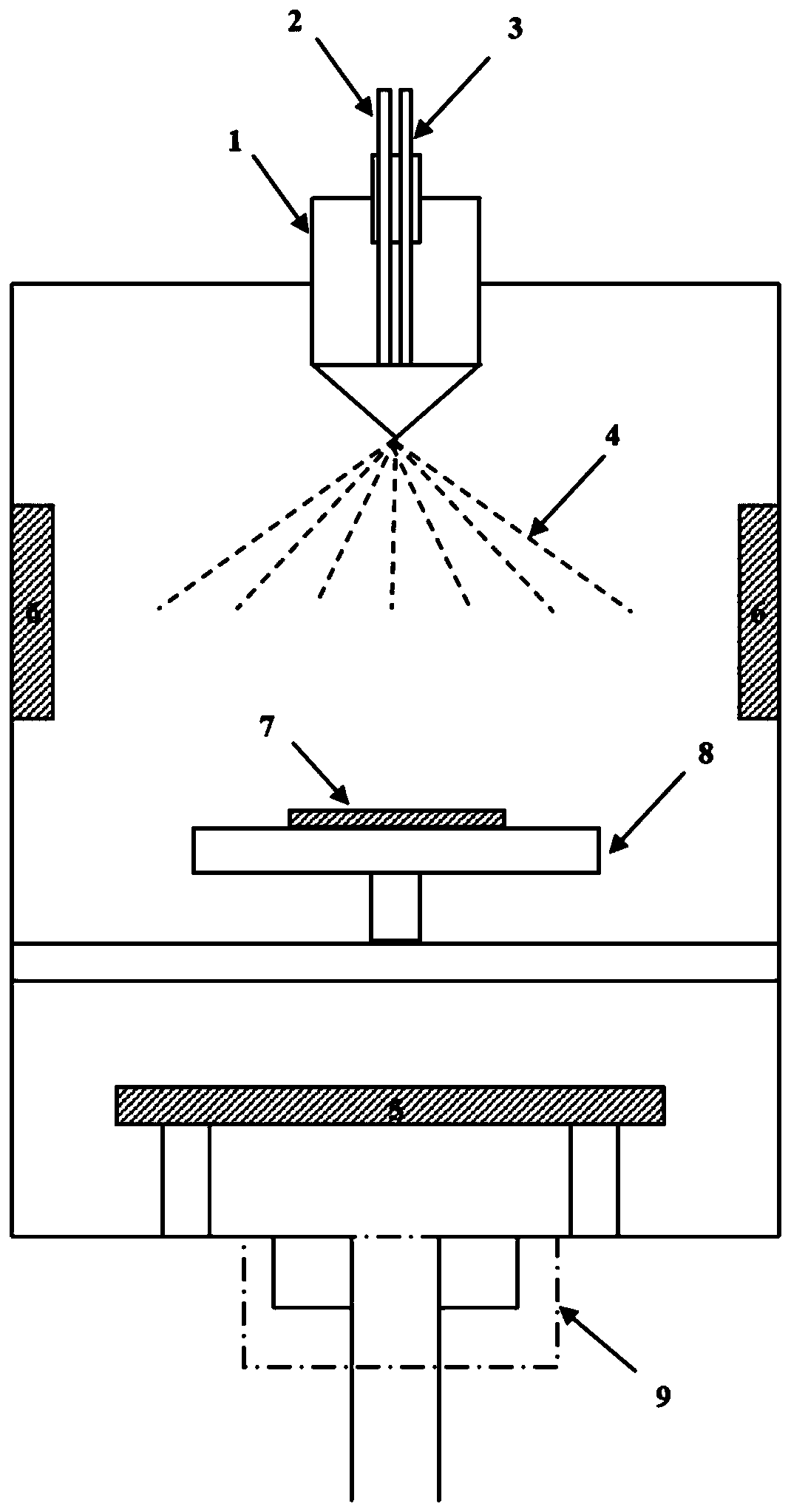

[0037] Embodiment 2: F, Sb-doped tin oxide film prepared by ultrasonic spray pyrolysis

[0038] Step 1, monobutyltin trichloride (MBTC), SbCl 3 and NH 4 F is used as a precursor, dissolved in a solvent in which ethanol and water are configured in proportion, as a precursor solution; step 2, depositing the precursor solution on the substrate by ultrasonic spray pyrolysis to form a tin oxide-based film, and finally performing heat treatment; step 3. Glue the two ends of the prepared electrothermal film semi-finished product to copper electrode strips with silver glue to form an electrothermal film device.

[0039] Through the doping ratio of F and Sb, the total doping ratio is controlled between 2% and 15%, and its square resistance changes between 60-300Ω / sq. As the doping ratio increases, the square resistance first decreases and then get bigger. Driven by a voltage of 6V, the highest stable temperature it can achieve is 56°C, and the thermal response time is 40 seconds. P...

Embodiment 3

[0040] Example 3: Preparation of double-layer composite electrothermal film

[0041] Step 1, monobutyltin trichloride (MBTC), SbCl 3 and NH 4 F is used as a precursor, dissolved in a solvent of ethanol and water in proportion, as precursor solution 1; in step 2, commercially available silver nanoparticles are dispersed in deionized water to form 0.01 mg.mL -1 solution as the precursor solution 2; step 3, dissolving the acrylic resin in the diluent to prepare a template agent of 0.4g / mL; step 4, dripping the template agent prepared in step 3 onto the quartz substrate, and using Apply evenly by spin coating, and then dry in the air to naturally form a chapped template network; step 5, add the precursor solution 2 to the substrate on which the template has been formed, and use the spin coating method to coat evenly, and at a certain temperature Dry in an oven, and clean the template agent with chloroform; step 6, deposit the precursor solution 1 on the substrate by ultrasonic s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com