A kind of preparation method of organic porous material

A porous material and organic technology, which is applied in the field of preparation of organic porous materials, can solve the problems of poor environmental protection, and achieve the effects of low cost, reduced types, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

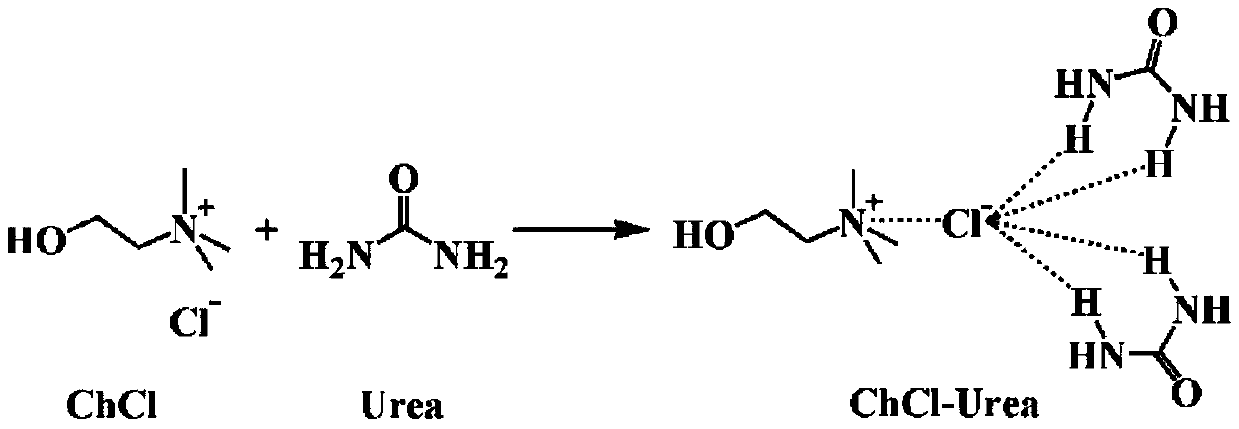

[0020] Add 0.083 mol of urea (Urea) and 0.042 mol of 2-hydroxyethyltrimethylammonium chloride (ChCl) into a round bottom flask, heat the reaction at 80°C for 30 minutes, and obtain uniform and stable ChCl-Urea ions Liquid, melting point: 12°C, the reaction formula is as follows:

[0021]

Embodiment 2

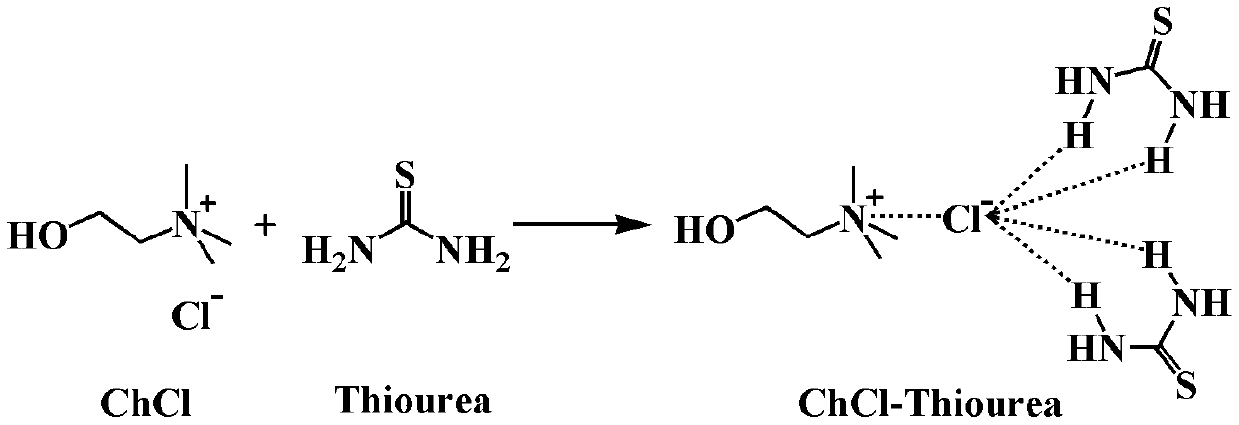

[0023] Add 0.083mol of Thiourea (Thiourea) and 0.042mol of 2-Hydroxyethyltrimethylammonium Chloride (ChCl) into a round-bottomed flask, and heat the reaction at 80°C for 120min to obtain uniform and stable ChCl-Thiourea Ionic liquid, melting point: 69°C, the reaction formula is as follows:

[0024]

Embodiment 3

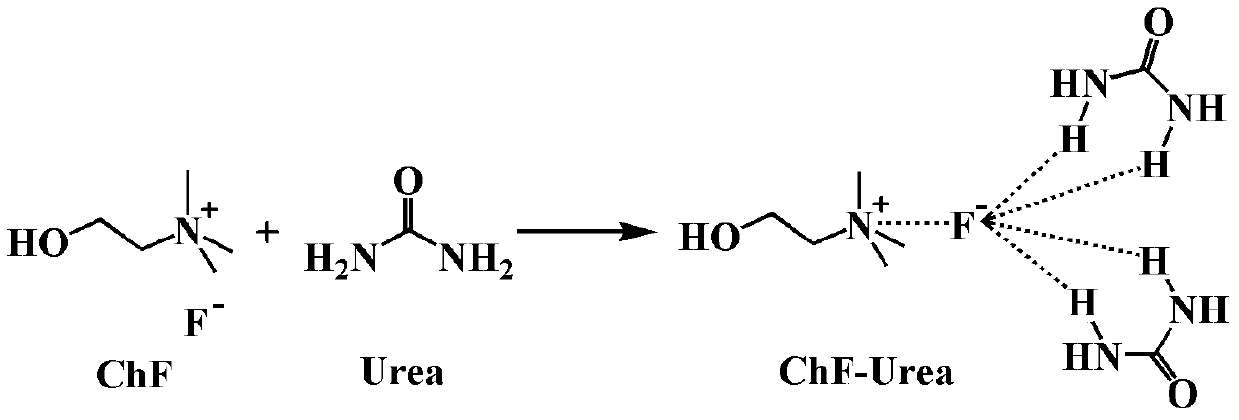

[0026] Add 0.083 mol of urea (Urea) and 0.042 mol of 2-hydroxyethyltrimethylammonium fluoride (ChF) into a round-bottomed flask, heat the reaction at 100°C for 30 minutes, and obtain uniform and stable ChF-Urea ions Liquid, melting point: 1°C, the reaction formula is as follows:

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com