A kind of preparation method of nanocellulose/graphene nanosheet composite film

A graphene nanosheet and nanocellulose technology, applied in the field of composite materials, can solve the problems of inability to reliably prepare a large number of large-sized graphenes, severe production conditions of epitaxial growth methods, and difficulty in controlling the size of graphenes. Fewer defects, low equipment requirements, and the effect of being conducive to industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

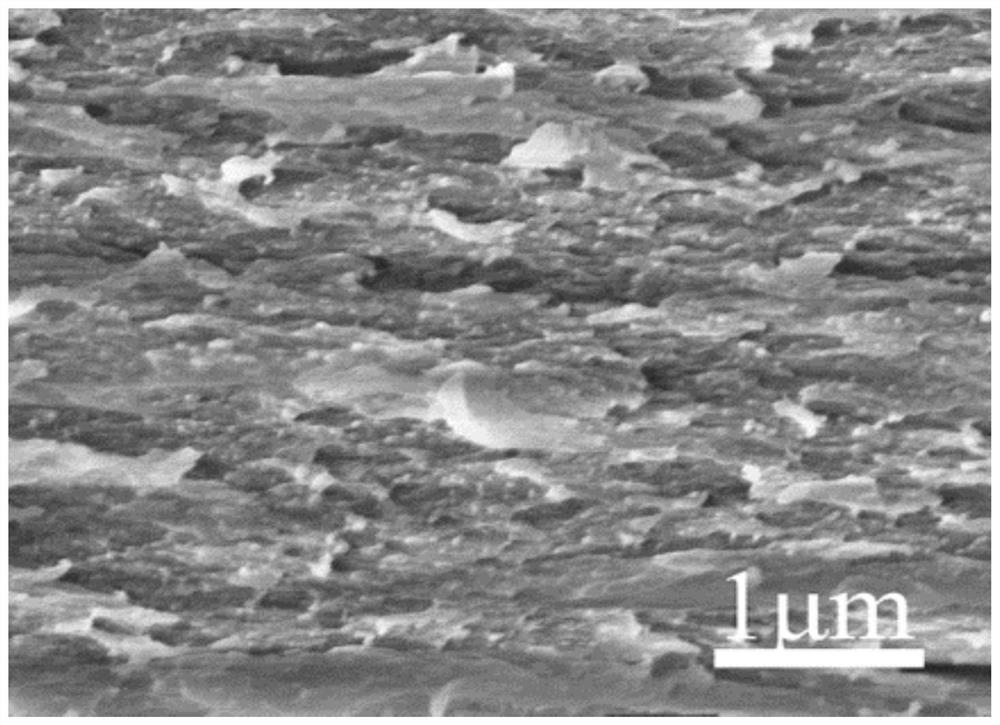

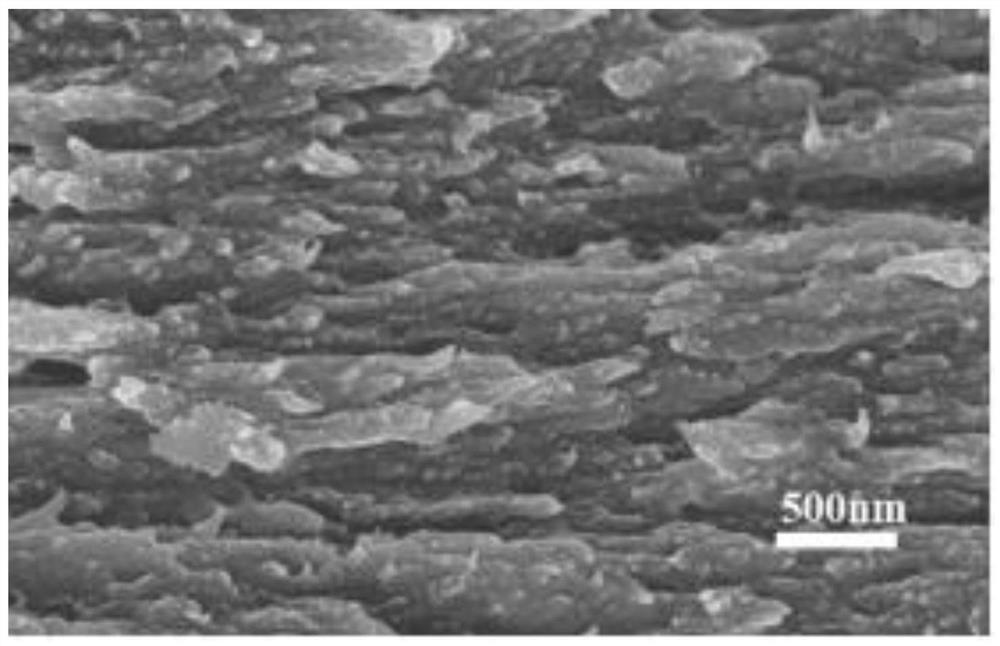

Image

Examples

Embodiment 1

[0037] Preparation of nanocellulose / graphene nanosheet composite film, the steps are as follows:

[0038] 1) Preparation of nanocellulose dispersion: take 0.01g TEMPO and 0.1g NaBr, add them together into 1000mL deionized water, stir magnetically at 10°C and 300r / min for 10min to fully mix until TEMPO and NaBr are completely dissolved, Then add 1g of cotton linters to the above system, then add 0.1g NaClO to the system, keep the pH of the system at 9 by dropwise adding 0.1mol / L NaOH solution, react at 10°C for 5h, and oxidize the fiber Then, it was washed with deionized water for more than 3 times, and dried to obtain TEMPO oxidized cellulose; then it was put into a beaker, added with deionized water to disperse, then mechanically stirred for 6 minutes and ultrasonically treated for 12 minutes to obtain a concentration of 0.3%. Nanocellulose dispersion liquid, namely 0.3% nanocellulose dispersion liquid;

[0039]2) Preparation of graphene nanosheets by liquid phase exfoliatio...

Embodiment 2

[0043] Preparation of nanocellulose / graphene nanosheet composite film, the steps are as follows:

[0044] 1) Preparation of nanocellulose dispersion: Take 0.01g TEMPO and 0.01g NaBr, add them together into 100mL deionized water, stir magnetically at 30°C and 600r / min for 20min to make them fully mix until TEMPO and NaBr are completely dissolved, Then add 0.1g of softwood bleached pulp to the above system, then add 1g of NaClO to the system, keep the pH of the system at 11 by adding 0.5mol / L NaOH solution dropwise, react at 30°C for 7h, and then oxidize the fiber Then, it was washed with deionized water for more than 3 times, and dried to obtain TEMPO oxidized cellulose; then it was put into a beaker, added with deionized water to disperse, then mechanically stirred for 6 minutes and ultrasonically treated for 6 minutes to obtain a concentration of 0.5%. Nanocellulose dispersion liquid, namely 0.5% nanocellulose dispersion liquid;

[0045] 2) Preparation of graphene nanosheets...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com