A positive electrode and its preparation method and a battery with the positive electrode

A positive electrode and positive electrode material technology, applied in the field of lithium-ion batteries, can solve the problems of reducing battery energy density, battery temperature rise, battery failure, etc., to achieve the effect of increasing energy density, shortening cycle time, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

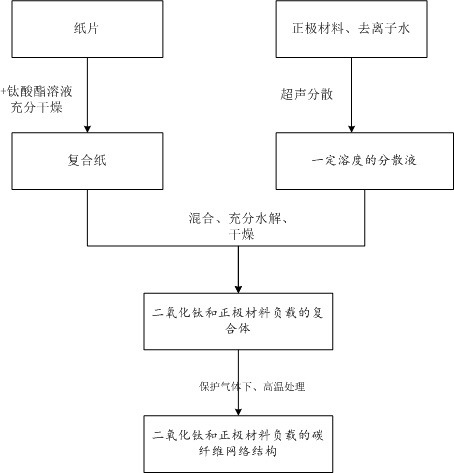

Method used

Image

Examples

Embodiment 1

[0025] A filter paper sheet with a thickness of 0.02 mm was soaked in a 1 mol / L n-butyl titanate solution for 0.5 hours, taken out and dried in an oven at 60 °C, and the lithium cobalt oxide material was mixed with deionized water for ultrasonic dispersion to obtain solubility. It is 20g / L lithium cobalt oxide dispersion, and then the dried filter paper is mixed with the dispersion for full hydrolysis reaction, taken out and dried in an oven at 80 °C to obtain the hydrolyzed titanium dioxide and lithium cobalt oxide supported on the filter paper Then, the composite was heated to 600 °C under nitrogen atmosphere for carbonization treatment for 10 h to obtain a carbon fiber network structure supported by nano titanium dioxide and lithium cobalt oxide, which is the positive electrode.

[0026] The obtained positive electrode film was cut into a certain size, and the graphite negative electrode, PE separator and carbonate electrolyte were prepared into a soft-packed battery cell, w...

Embodiment 2

[0028] A filter paper sheet with a thickness of 0.05 mm was soaked in a 1 mol / L n-butyl titanate solution for 1 hour, taken out and dried in an oven at 80 °C, and the lithium iron phosphate material was mixed with deionized water for ultrasonic dispersion to obtain the solubility. It is a 100g / L lithium iron phosphate dispersion, and then the dried filter paper is mixed with the dispersion to conduct a sufficient hydrolysis reaction, taken out and dried in an oven at 100 ° C to obtain the hydrolyzed titanium dioxide and lithium iron phosphate. Loaded on the filter paper Then, the composite was heated to 1000 °C under nitrogen atmosphere for carbonization treatment for 2 h to obtain a carbon fiber network structure supported by nano-titanium dioxide and lithium iron phosphate, which is the positive electrode.

[0029] The obtained positive electrode film was cut into a certain size, and the graphite negative electrode, PE separator and carbonate electrolyte were prepared into a ...

Embodiment 3

[0031] A filter paper sheet with a thickness of 0.1 mm was soaked in a 1 mol / L n-butyl titanate solution for 2 hours, taken out and dried in an oven at 100 °C, and the nickel cobalt lithium manganate NCM523 material was mixed with deionized water for ultrasonic dispersion. The nickel-cobalt-manganese NCM523 dispersion with a solubility of 200 g / L was obtained, and then the dried filter paper was mixed with the dispersion to carry out a sufficient hydrolysis reaction, and then dried in an oven at 60 °C to obtain hydrolyzed titanium dioxide and nickel-cobalt-manganese. The composite of lithium oxide NCM523 loaded on filter paper, and then heated to 800 ℃ under nitrogen atmosphere for carbonization treatment for 6 h, to obtain the carbon fiber network structure supported by nano titanium dioxide and lithium nickel cobalt manganate NCM523, which is the positive electrode.

[0032] The obtained positive electrode film was cut into a certain size, and the graphite negative electrode,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com