Biomass boiler fuel pretreatment method, pretreatment device and flue gas denitrification method

A technology for biomass boilers and boiler flue gas, applied in separation methods, chemical instruments and methods, coking ovens, etc., can solve the problems of boiler efficiency decline, safety hazards, high biomass pyrolysis temperature, etc., to reduce boiler slag discharge, The effect of ensuring heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

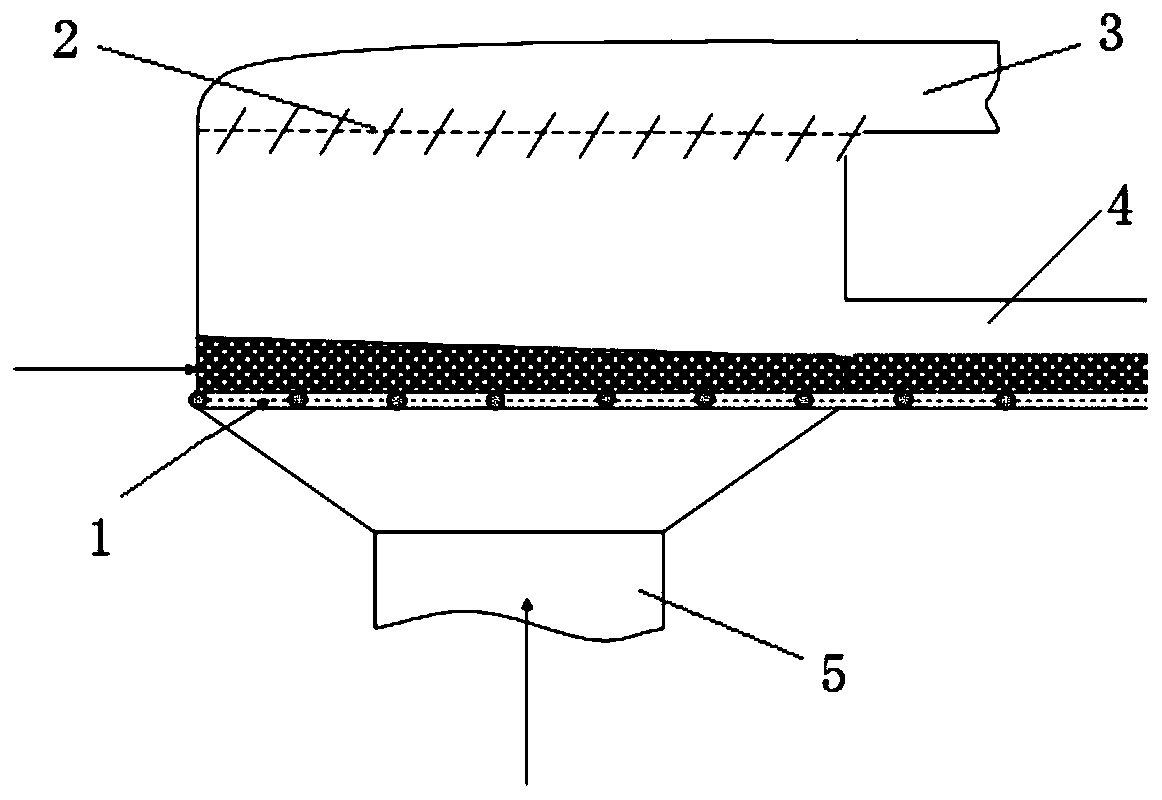

Image

Examples

preparation example Construction

[0063] The preparation method of molecular sieve refers to the following steps:

[0064] Weigh a certain amount of roasted MCM-41 molecular sieve, add a certain amount of toluene and aminopropyltrimethoxysilane, and reflux for 8 hours. After the product is centrifuged, it is first washed with methanol, and then washed with distilled water until there is no unreacted Silicone and solvent toluene. Dry at 100-120°C to obtain organic functionalized MCM-41 molecular sieve.

[0065] The functionalized MCM-41 molecular sieve is mixed with a mixture of copper nitrate and iron nitrate at a certain concentration, and the molar ratio of copper nitrate and iron nitrate is 1:3-6. Stir at room temperature for 10 hours, centrifuge, and ultrasonically clean with distilled water for 3-5 times until there are no copper ions and iron ions in the solution. The cleaned molecular sieve is dried and calcined to obtain the required catalyst.

[0066] The molecular sieve can also be other kinds of ...

Embodiment 1

[0070] The sawdust is crushed, and the particle size after crushing is less than 0.7cm;

[0071] Spray the catalyst in the crushed sawdust, mix well, the catalyst is a molecular sieve loaded with copper oxide and iron oxide, the molar ratio of copper oxide and iron oxide is 1:2, and the molecular sieve is MCM-41 molecular sieve;

[0072] The mass ratio of sawdust to catalyst is 1000:2, and the mass of copper oxide and iron oxide loaded in each gram of molecular sieve is 0.05g.

[0073] Extract the flue gas at 350°C from the boiler, pass it into the biomass material mixed with the catalyst, and pyrolyze the wood chips. The pyrolysis time is 10 minutes, and the pyrolysis gas and charcoal are obtained. The carbon content in the charcoal is 90%. There is basically no tar in the solution gas.

[0074] After the pyrolysis gas is washed with water, it is mixed with the secondary air at a volume ratio of 1:2, and passed into the boiler to reduce the nitrogen oxides in the boiler flue...

Embodiment 2

[0076] Crushing the corn stalks, the particle size after crushing is less than 0.1cm;

[0077] Spray the catalyst in the crushed corn stalks, mix well, the catalyst is a molecular sieve loaded with copper oxide and iron oxide, the molar ratio of copper oxide and iron oxide is 1:2, and the molecular sieve is MCM-41 molecular sieve;

[0078] The mass ratio of corn stalks to the catalyst is 1000:2, and the mass of copper oxide and iron oxide loaded in each gram of molecular sieve is 0.2g.

[0079] Extract the flue gas at 300°C from the boiler, pass it into the corn stalks mixed with the catalyst, and pyrolyze the corn stalks for 20 minutes to obtain pyrolysis gas and charcoal. The content of carbon in the charcoal is 85%. There is basically no tar in the solution gas.

[0080] After the pyrolysis gas is washed with water, it is mixed with the secondary air at a volume ratio of 1:1.8 and passed into the boiler to reduce the nitrogen oxides in the boiler flue gas to nitrogen to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com