Method for preparing 1,5-pentanediol by using catalyst containing molybdenum disulfide for catalytic hydrogenation of tetrahydrofurfuryl alcohol

A technology for catalytic hydrogenation of tetrahydrofurfuryl alcohol, applied in catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as copper chromate environmental pollution, increased processing costs, and long synthesis routes, etc., to achieve The effect of high selectivity, good stability and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

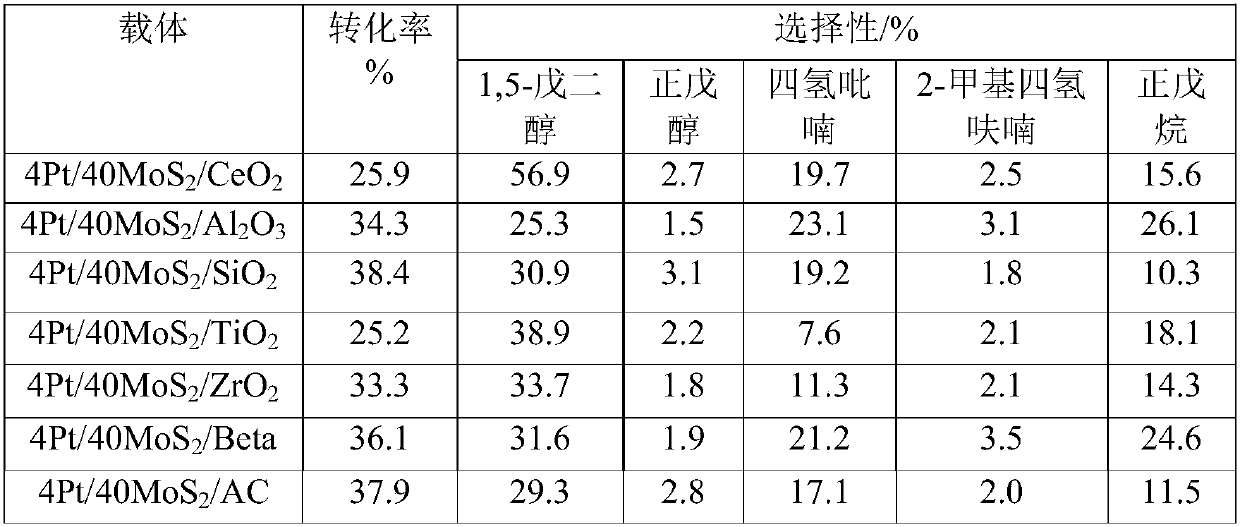

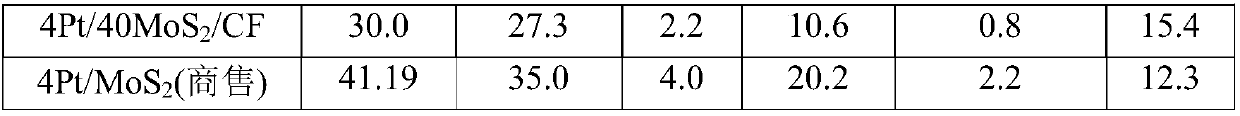

[0019] Preparation of supported molybdenum sulfide catalyst: 2.5 mmol of sodium molybdate and 20 mmol of sodium sulfide are co-dissolved in 100 ml of deionized water to form a mixed solution, 10 ml of ethanol is added to it, and then 1 g of ceria powder is dispersed in the above solution. After the cerium dioxide was uniformly dispersed, 2 ml of concentrated hydrochloric acid was added to form a precipitate. The catalyst carrier and the precipitate were filtered, washed with deionized water, and dried at 120° C. overnight. The obtained catalyst was reduced in a tube furnace at 450 °C for 0.5 h under a hydrogen atmosphere to obtain a supported molybdenum sulfide catalyst MoS 2 / CeO 2 .

[0020] In the same way, MoS can be prepared separately by replacing the carrier with alumina, silica, titania, zirconia, ceria, molecular sieve, activated carbon, and carbon fiber. 2 / Al 2 O 3 , MoS 2 / SiO 2 , MoS 2 / TiO 2 , MoS 2 / ZrO 2 , MoS 2 / Beta, MoS 2 / AC, MoS 2 / CF and othe...

Embodiment 2

[0022] Hydrogenation metal loading: 1 g MoS 2 / CeO 2 Put it in a beaker, add a chloroplatinic acid solution containing 0.2 mmol Pt, stir evenly, place it at room temperature for 12 hours, and place it in a 120°C oven overnight to dry. 4Pt / MoS can be prepared by reducing the obtained catalyst at 300C for 1 h under a hydrogen atmosphere in a tube furnace 2 / CeO 2 .

[0023] 4Pt / MoS can be prepared by the same method 2 / Al 2 O 3 , 4Pt / MoS 2 / SiO 2 , 4Pt / MoS 2 / TiO 2 , 4Pt / MoS 2 / ZrO 2 , 4Pt / MoS 2 / Beta, 4Pt / MoS 2 / AC, 4Pt / MoS 2 / CF.

[0024] commercial MoS 2 As a carrier, 4Pt / MoS can be obtained by the same method 2 catalyst.

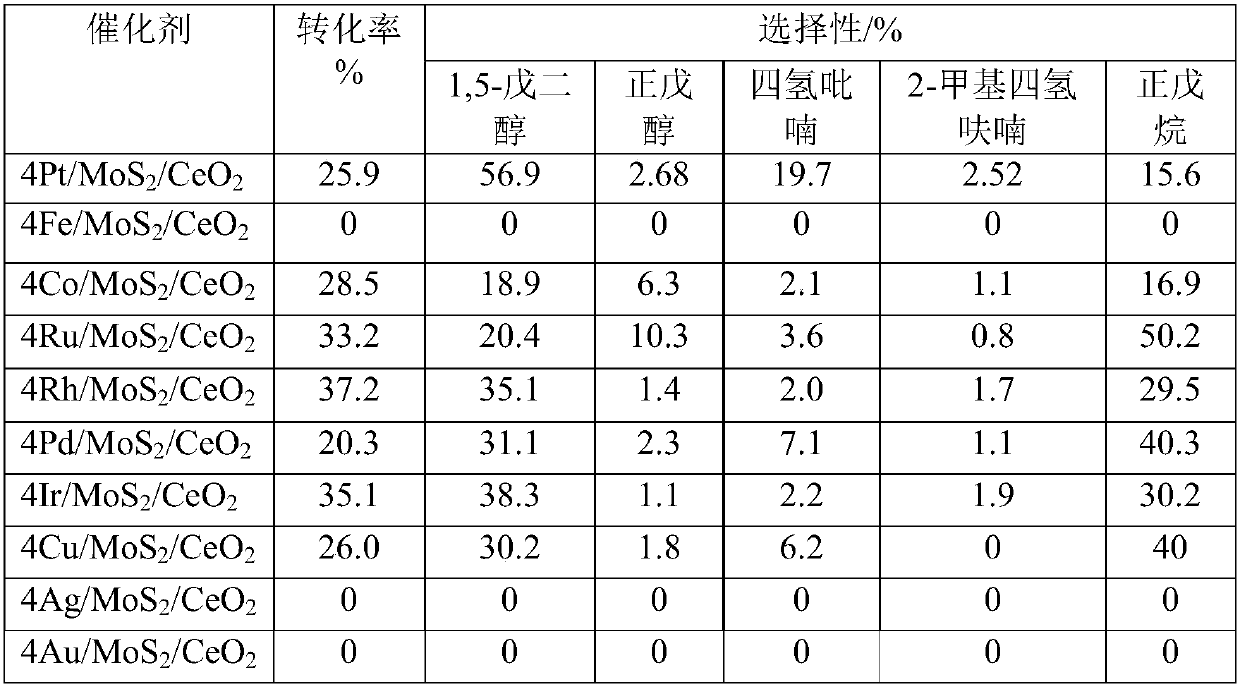

[0025] Molybdenum sulfide catalysts containing different hydrogenation metals can be obtained by changing the hydrogenation metal components.

Embodiment 3

[0027] Experiment of catalytic conversion of tetrahydrofurfuryl alcohol:

[0028] 20g of 5wt% tetrahydrofurfuryl alcohol aqueous solution was added to a 100ml Hastelloy reactor, 0.1g of catalyst and a magnetic stirring rotor were added at the same time, nitrogen was introduced for three times, and then replaced by hydrogen five times. The initial pressure of hydrogen was 4MPa, and magnetic stirring was set. The rotational speed of 800rpm / min, the reaction temperature was 250°C, and the reaction time was 8 hours. After the reaction was completed, the raw materials and products were quantified by the internal standard method using the FID detector. Conversion and selectivity are calculated in moles of carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com