Lithium ion battery negative material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex process, non-uniform performance, easy powdering, etc., to alleviate the volume effect, the preparation method is simple, and the The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

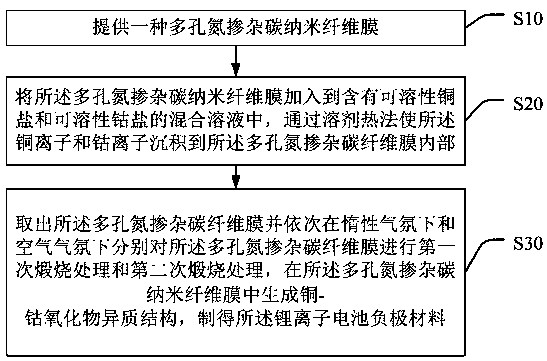

[0031] see figure 1 , the present invention provides a flow chart of a preferred embodiment of a preparation method of a negative electrode material for a lithium ion battery, as shown in the figure, which includes steps:

[0032] S10, providing a porous nitrogen-doped carbon nanofiber membrane;

[0033] S20, adding the porous nitrogen-doped carbon nanofiber membrane into a mixed solution containing soluble copper salt and soluble cobalt salt, and depositing the copper ions and cobalt ions on the porous nitrogen-doped carbon fiber membrane by solvothermal method internal;

[0034] S30. Take out the porous nitrogen-doped carbon fiber membrane, and perform the first calcination treatment and the second calcination treatment on the porous nitrogen-doped carbon fiber membrane under an inert atmosphere and an air atmosphere respectively. A heterogeneous structure of copper-cobalt oxide is generated in the heterocarbon nanofiber film, and the negative electrode material of the lit...

Embodiment 1

[0047] Weigh polyacrylonitrile (PAN) and cetyltrimethylammonium bromide (CTAB) with a mass ratio of 10:2 and add them to N,N-dimethylformamide (DMF) solution and stir vigorously to obtain PAN Spinning solution, the spinning solution is passed through an electrospinning machine under the conditions of 15kv high voltage and a high speed of 800 revolutions per minute using 21 conductive needles to obtain a filamentous product; the filamentous product is in the air at 280 ° C Pre-oxidize for 2 hours, then carbonize and sinter at 800°C, keep warm for 2 hours, and cool to room temperature to obtain a porous carbon fiber substrate. A water / ethylene glycol mixed solvent is used, the volume of the solvent hot liquid is 30ml, the molar ratio of copper nitrate to cobalt nitrate is 1:1, and the mass of porous carbon fiber added is 20mg. The solvothermal product was first calcined at 400 °C for 2 h under the protection of nitrogen, and then oxidized at a low temperature of 200 °C for 6 h t...

Embodiment 2

[0049] Weigh polyacrylonitrile (PAN) and cetyltrimethylammonium bromide (CTAB) with a mass ratio of 10:1 and add them to the N,N-dimethylformamide solution. Stir vigorously in a methylformamide (DMF) solution to obtain a PAN spinning solution, which is obtained by electrospinning the spinning solution with 20 conductive needles under the condition of 15kv high voltage and a high speed of 900 revolutions per minute through an electrospinning machine. Filamentous product; finally pre-oxidized in air at 280°C for 2h, then carbonized and sintered at 700°C, kept for 2h, cooled to room temperature to obtain a porous carbon fiber substrate. A water / ethylene glycol mixed solvent is used, the volume of the solvent hot liquid is 30ml, the molar ratio of copper sulfate to cobalt nitrate is 1.5:1, and the mass of the porous carbon fiber added is 25mg. The solvothermal product was first calcined at 400 °C for 2 h under the protection of nitrogen, and then oxidized at a low temperature of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com