Method for preparing composite polymer solid electrolyte

A solid electrolyte and composite polymer technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of inability to meet the use requirements of solid-state lithium-ion batteries, poor mechanical and thermal stability, and poor nanoparticle dispersion. Lithium dendrite growth, improved safety and energy density, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0022] Step 1: Weigh 2.0g of aramid fibers and 1.0g of potassium hydroxide into a certain amount of dimethyl sulfoxide, stir at room temperature for 7 days (or 3 days at 60°C) until the aramid fibers are completely dissolved , to obtain a well-dispersed aramid nanofiber solution, wherein the concentration of aramid nanofiber is about 12.5mg / mL;

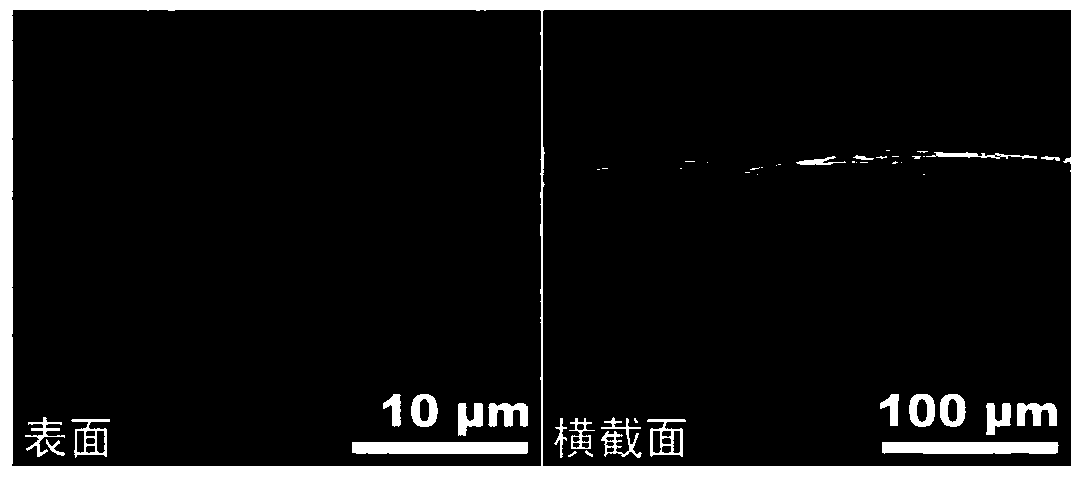

[0023] Step 2: Apply the above solution to a clean glass plate by the scraper method, and transfer it to water to stand still for 0.5h until the aramid nanofiber gel film is detached from the glass plate, and then transfer the gel film to Stand still in water / isopropanol solution (volume ratio 1:1) for 1–24 hours to fully replace dimethyl sulfoxide with water / isopropanol solution;

[0024] Step 3: Put the above-mentioned aramid nanofiber gel film into a freeze-drying box, and dry it under vacuum for 24-48 hours to completely evaporate the solvent to obtain a three-dimensional porous aramid nanofiber film for use;

[0025] Step 4: Wei...

Embodiment example 2

[0028] Step 1: Weigh 2.0g of aramid fibers and 1.0g of potassium hydroxide into a certain amount of dimethyl sulfoxide, stir at room temperature for 7 days (or 3 days at 60°C) until the aramid fibers are completely dissolved , obtain a well-dispersed aramid nanofiber solution, wherein the concentration of the aramid nanofiber is about 10 mg / mL, ready for use;

[0029] Step 2: Put 50 mg of lithium titanium aluminum phosphate nanoparticles into 1 mL of dimethyl sulfoxide and stir for 24 hours to obtain a well-dispersed solution of lithium titanium aluminum phosphate nanoparticles with a concentration of about 50 mg / mL;

[0030] Step 3: Under vigorous stirring, take out 5 mL of the aramid nanofiber solution described in step 1, and add it dropwise to the lithium titanium aluminum phosphate nanoparticle solution described in step 2, and continue stirring for 24 hours to obtain a dispersity Better aramid nanofiber / lithium titanium aluminum phosphate nanoparticle composite solution;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com