Biodegradable high-barrier liquid packaging film

A biodegradable material and packaging film technology, applied in the field of high barrier liquid packaging film and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

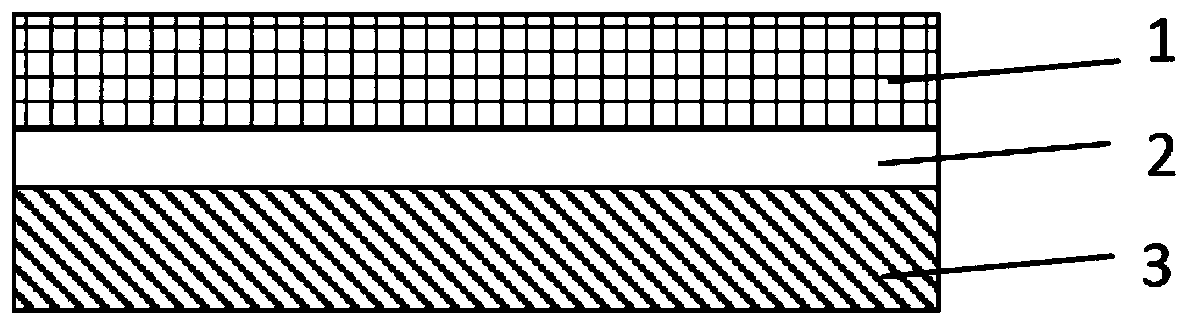

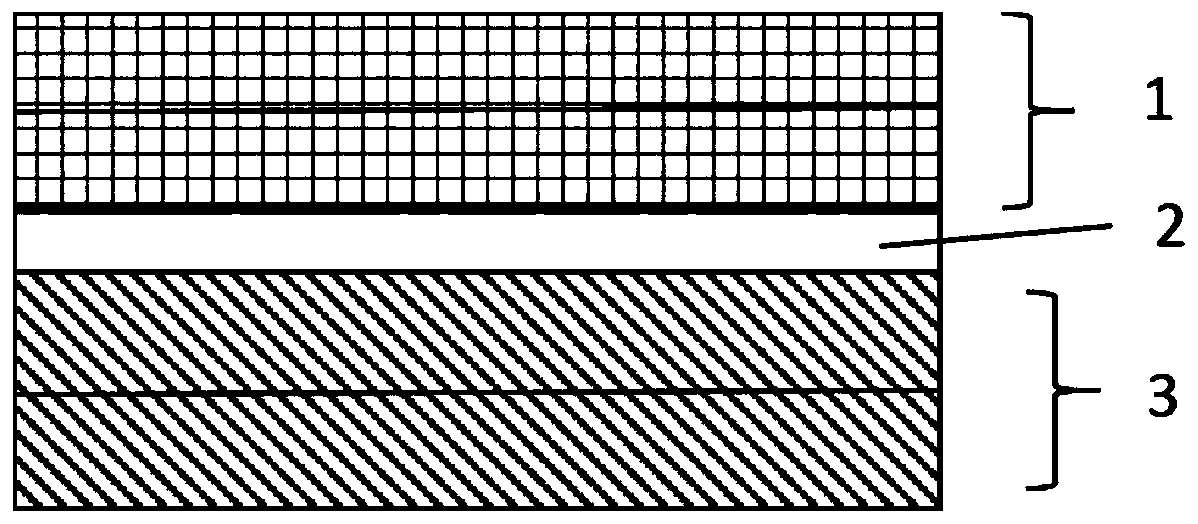

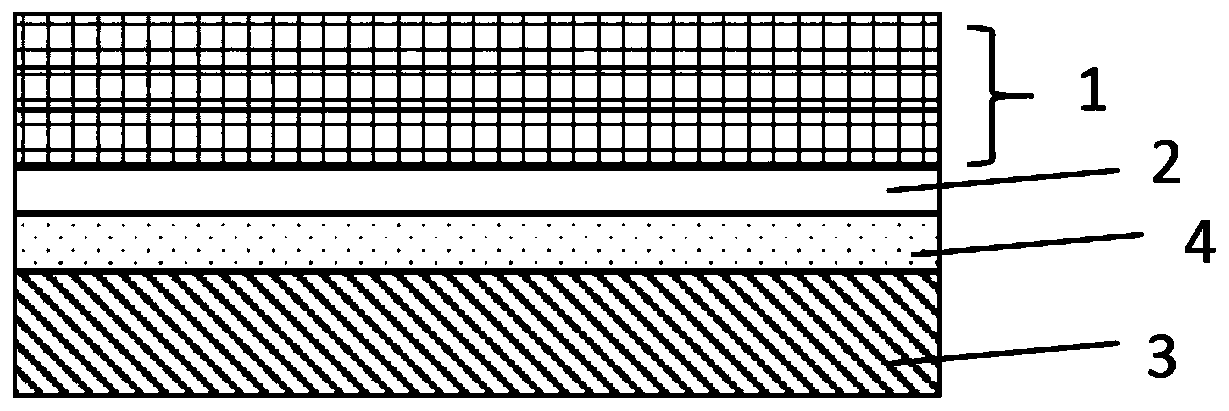

Image

Examples

Embodiment 1

[0110] Use a plastic five-layer co-extrusion blown film machine, add a mixture of polylactic acid (4032D) and epoxy resin (Nanya 904) to the outer 1 and outer 2 layer material boxes of the blown film machine, and the mixing ratio is: (99:1) , add ethylene-vinyl alcohol copolymer (Japan Kuraray G156) to the middle layer material box of the blown film machine, add PHB-PHV (Metabolix) and antioxidant (1010) to the inner 1 and inner 2 material boxes of the blown film machine The mixture with polyethylene (2420H), the mixing ratio is: (90:0.1:9.9), and the processing temperature is:

[0111] Outer 1 and layer extruder 120-190°C

[0112] Middle layer extruder 190-230℃

[0113] Inner 1 and inner layer extruder 120-200°C

[0114] Head temperature: 170-200°C

[0115] Co-extruded into a biodegradable liquid packaging film with a thickness of 120 μm, printed on the outer layer of the film, and cut into a finished film with a width of 350 cm. The measured oxygen transmission rate of t...

Embodiment 2

[0117] (1) With a plastic single-layer casting machine, the mixture of polybutylene succinate (PBS), starch and oxazoline high-reactivity polymer (XH-500) is the film material, and the mixing ratio is: ( 80:19:1), the processing temperature is: extruder 120-170°C, head 120-180°C, extruded into a heat-sealing layer film with a thickness of 60μm.

[0118] (2) Coating the polyvinyl alcohol coating liquid on the EDM-treated surface of the above-mentioned heat-sealing layer film with a coating machine to a coating thickness of 1 μm.

[0119] (3) Laminate the coated surface of the above-mentioned coated heat-sealing layer film with 90 μm thick paper with an adhesive using a dry laminating machine, and put it into a curing chamber for 24 hours of curing. The temperature of the curing chamber is 50°C.

[0120] (4) One side of the above-mentioned cured composite film paper is coated with cellulose varnish with a coating machine, and printed on the varnish level, and then cut into a fin...

Embodiment 3

[0123] (1) Using a plastic single-layer blown film machine, the film material is a mixture of polycaprolactone (6800), antibacterial agent (SX25) and styrene-maleic anhydride copolymer (Kray Willy 3000P), and the mixing ratio is: (90:0.02:9.98), the processing temperature is: extruder 130-190°C, head 130-200°C, extruded into a heat-sealing layer film with a thickness of 40μm.

[0124] (2) Use a plastic single-layer blown film machine, using a mixture of polylactic acid (4032D), organic peroxide and maleic anhydride graft-modified polyethylene (E226) as the material, and the mixing ratio is: (90:0.01:9.99 ), the processing temperature is: extruder 130-190°C, head 130-200°C, extruded into a protective layer film with a thickness of 60 μm.

[0125] (3) Use a dry compound machine to glue and compound the above-mentioned heat-sealing layer film and the spark surface of the protective layer film with a polyvinyl alcohol adhesive, and then put it into a curing chamber for curing for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Oxygen transmission rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com