Pretreatment method and fermentation process of mixed lignocellulose

A technology of lignocellulose and fermentation process, which is applied in the field of mixed lignocellulose pretreatment method and fermentation process thereof, can solve the problems of affecting the process of fermented products, increasing the cost of subsequent processing, and high biomass slurry, saving chemical reagents, The effect of reducing the economic risk of enterprises and promoting the fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] After mixing various lignocellulose raw materials and performing pretreatment, lignocellulose slurry is obtained.

[0035] The present embodiment uses crop biomass as raw material to carry out the technique of ethanol fermentation according to the following steps:

[0036] (1) Biomass mixing. Corn, wheat and rice stalks were mixed and added into the reactor so that the substrate mass concentration was 10%, sodium hydroxide solution (2% w / w) was added, and pretreated at 121° C. for 20 minutes. Use hydrochloric acid to adjust the pH to 6-7, place the pretreated slurry in an oven, and dry the water at 60°C to 10-20% for use;

[0037] (2) Hydrolysis of mixed biomass. Add the pretreated slurry into the reactor, the substrate mass concentration is 10%, adjust the pH to 4.7-4.9, add Ctec 2 (Beijing Novozymes) enzyme, and carry out in a shaking box (250rpm) at 50°C enzymatic reaction;

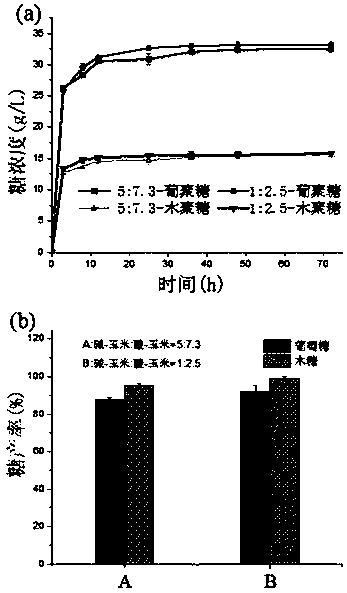

[0038] (3) Ethanol fermentation. Add 60ml of enzymatic hydrolysis solution to a 150ml r...

Embodiment 2

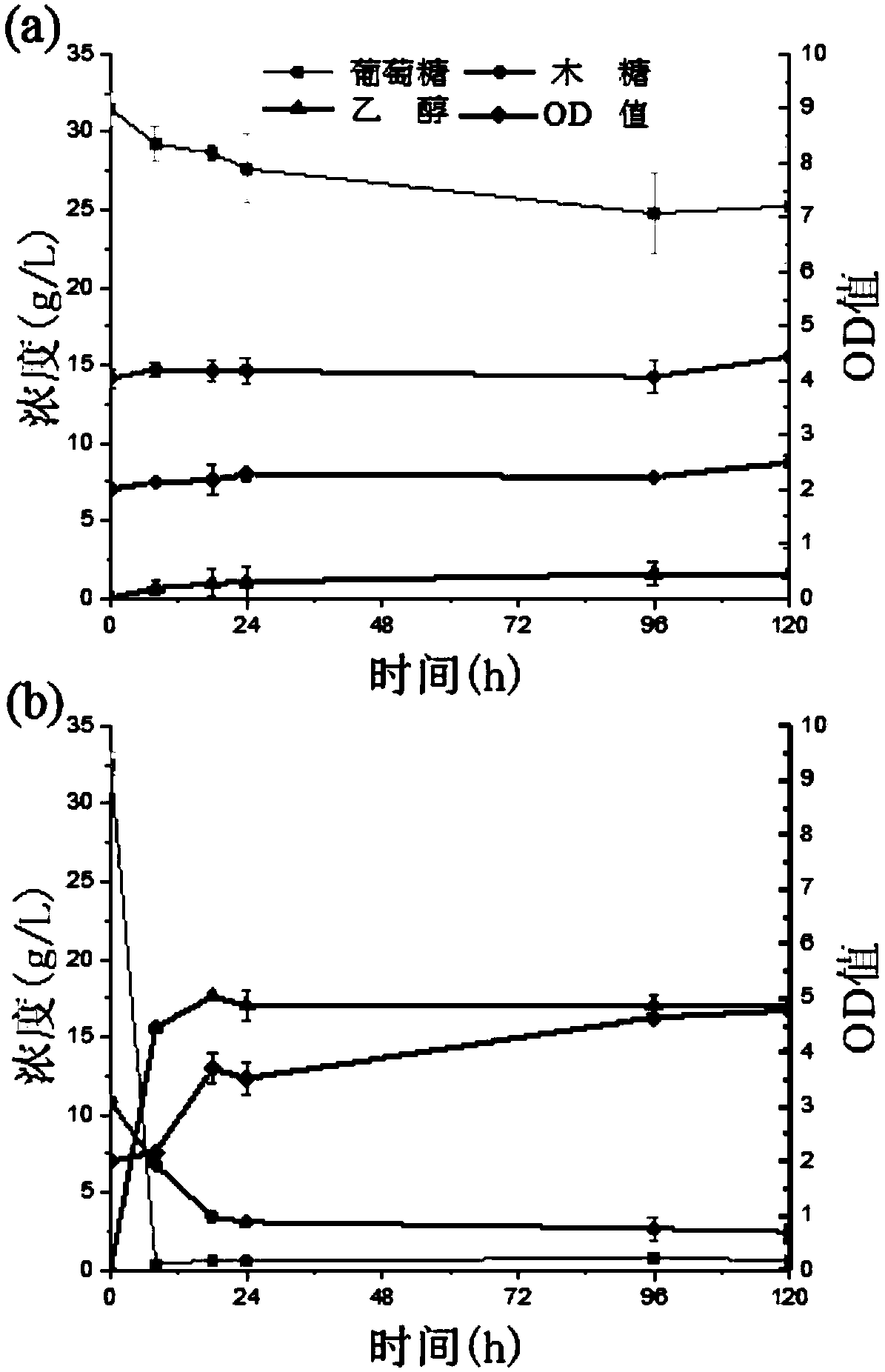

[0040]Mix corn, wheat and rice stalks into the reaction kettle, add dilute sulfuric acid solution, so that the mass concentration of the straw substrate is 10%, and the sulfuric acid concentration is 1%. Pretreat at 160°C for 10 minutes, use sodium hydroxide to adjust the pH to 6.0-7.0, then place the pretreated slurry in an oven, and dry the water at 60°C to 10%-20%. The mass concentration of the substrate is 10%, the pH is adjusted to 4.6-7.0, and Ctec 2 Novozyme enzyme is added. Adjust to pH=5.5-6.5 after enzymatic hydrolysis, add yeast powder and peptone, according to the initial OD 600 =1.0-2.0 The bacteria of Zymomonas mobilis 8b were added, and the fermentation was carried out in a shaking box (150 rpm) at 30°C.

Embodiment 3

[0042] Firstly, one kind of lignocellulose raw material is subjected to acid pretreatment or alkaline pretreatment, and then different kinds of lignocellulose are sequentially added in batches to obtain a pretreatment slurry of mixed lignocellulose.

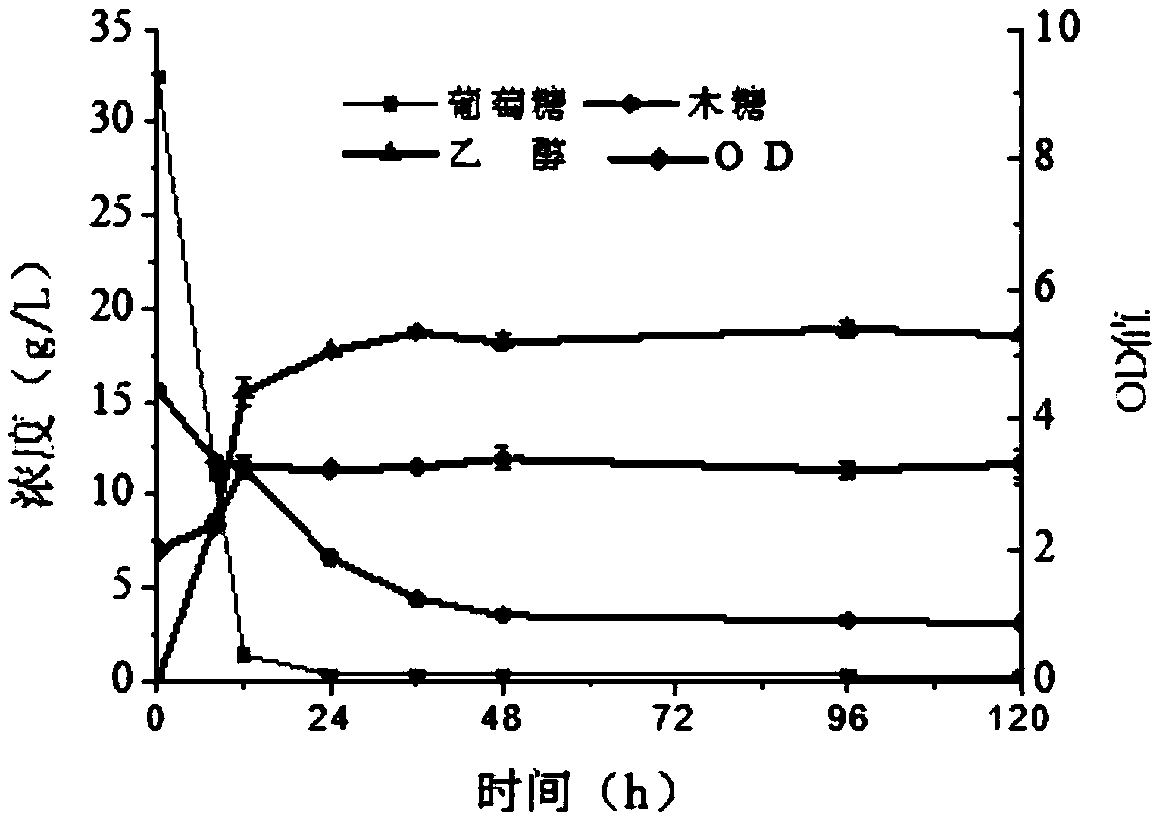

[0043] In this embodiment, poplar wood with a dense structure is added to the reactor for pretreatment, and then easily degradable corn stalks are added. Dilute sulfuric acid was added to make the substrate mass concentration 10%, and pretreatment was performed under the optimum reaction conditions for pretreatment. The pH of the pretreatment slurry was then adjusted to 6.0-7.0 using hydrochloric acid / sodium hydroxide. The pretreated mixed slurry is placed in an oven, and dried at 60°C to a moisture content of 10-20% for use. The mass concentration of the substrate is 10%, the conditions are pH=4.6-7.0, and Ctec 2 Novozymes enzyme is added to carry out the enzymatic hydrolysis reaction. After enzymatic hydrolysis, adjust the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com