A composite collagen dressing for repairing difficult-to-heal wounds and its preparation method

A technology for wound repair and collagen, which is applied in medical science, absorbent pads, bandages, etc., can solve the problems of long action time and achieve the effects of prolonging the degradation time, simple and controllable preparation process, and increasing the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 3

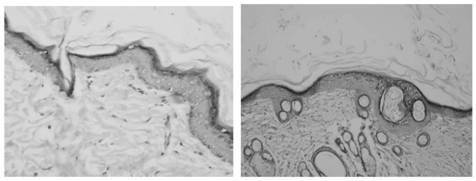

[0037] The rat material of Experimental Example 3 is provided by the Experimental Animal Center of Tianjin Medical University. The first group of embodiments, the composite collagen dressing for refractory wound repair of the present invention

[0038] This group of examples provides a composite collagen dressing for the repair of difficult-to-heal wounds. The "difficult-to-heal wounds" in this article refer to wounds with poor self-healing ability and healing time of more than 2 months, generally including chronic difficult-to-heal wounds and traumatic wounds. Difficult to heal wounds.

[0039] All embodiments of this group all possess following common features:

[0040] The weight ratio of type I collagen to type III collagen in the composite collagen dressing is 99.99-85:0.01-15;

[0041] Type III collagen can be as low as 0.01. Although such a small amount, it plays a key role in the composite collagen auxiliary material of the present invention. The inventor unexpectedly...

experiment example 1

[0058] The preparation technology of experimental example 1 layered film

[0059] (1) Collagen types I and III (w / w:99.3:0.7) with a certain mass concentration were homogenized and spread in a container and placed in an ultra-low temperature refrigerator at -80°C for 24 hours to form an outer homogenate film;

[0060] (2) Spread the homogenate of type I and III collagen (w / w97:3) with a certain mass concentration on the outer homogenate membrane and place it in -80°C for 24 hours to form a contact layer homogenate membrane. Dry in a freezer vacuum dryer at -50°C for 24 hours to form a layered film.

[0061] The content of type III collagen in the homogenized membrane of the outer layer is 0.01-1%, and the content of collagen III in the homogenized membrane of the contact layer is 1-15%.

experiment example 2

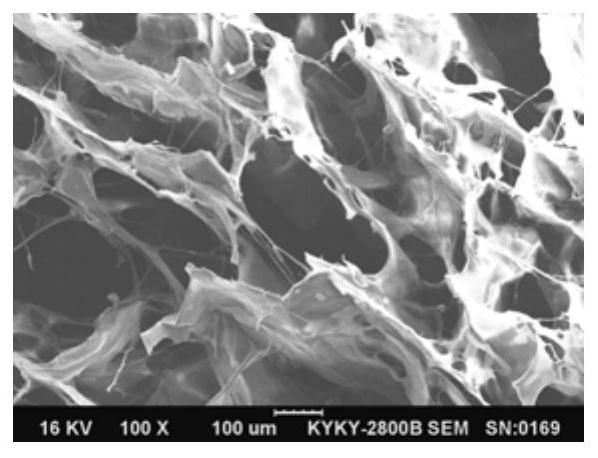

[0062] The preparation technology of experimental example 2 fiber film

[0063] (1) Weigh type I collagen and type III collagen, disperse them in distilled water according to the ratio of 93:7 (W / W), and mix them with a high-speed mixer to prepare a homogenate with a certain mass concentration, and add a cross-linking agent to cross-link Prepared into collagen copolymer;

[0064] (2) Dissolving the cross-linked copolymer in a hexafluoroisopropanol solution, placing the solution in a liquid storage tube of a high-voltage electrospinning machine, and making a chemically composite collagen fiber membrane by electrospinning.

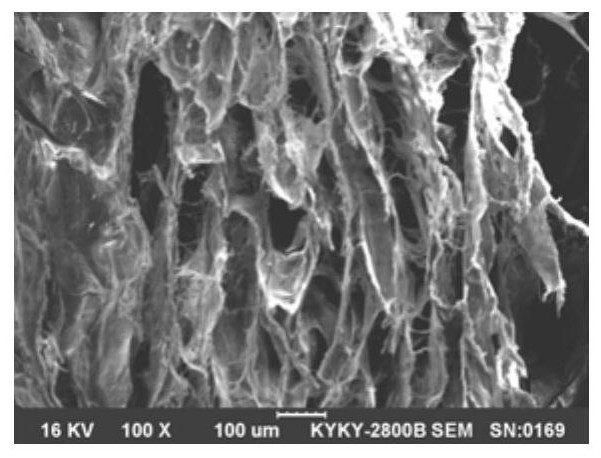

[0065] The preparation process of the sponge-like material includes dispersion-prefreeze molding-freeze-drying, and the general method for preparing sponges in the art can be adopted. Different collagens are mixed in proportion, homogenized, defoamed, pre-frozen in a mold, and freeze-dried.

[0066] Application of experimental example 3 composite collagen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com