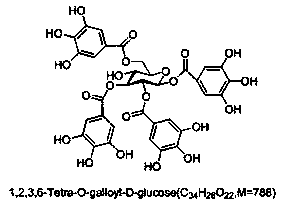

Mechanochemical extraction method for preparing hydrolysable-tannin crude extract from trapa Sp. pericarps

A technology of hydrolyzing tannins and mechanochemistry, which is applied in chemical instruments and methods, organic chemistry, preparation of sugar derivatives, etc., can solve the problems of long extraction time, noise pollution, long heating time, etc., to improve extraction yield and reduce Waste of resources, fast and efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

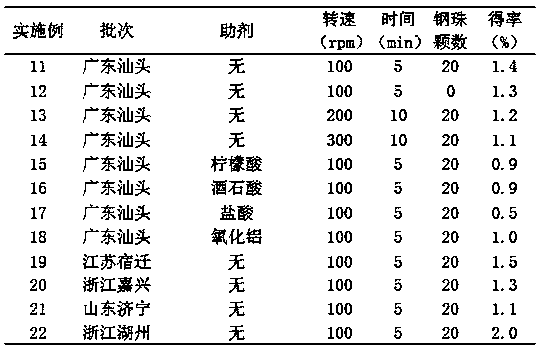

Embodiment 1

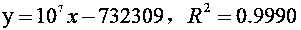

[0038] The water chestnut shell produced in Shantou, Guangdong is crushed and passed through an 80-mesh sieve to obtain water chestnut shell powder with a mesh size greater than 80 mesh. Add 1.01 g of the water chestnut shell powder in the stainless steel ball mill tank, add 20 stainless steel ball mill beads with a diameter of 10 mm (ball milling filling rate 20.9%) and 0.15 g auxiliary agent (the auxiliary agent is sodium bicarbonate), and the ball milling time is 5 min , the milling speed is 100 rpm.

[0039] Weigh 0.51 g of the ball-milled powder, mix the ball-milled powder with ethanol aqueous solution (V ethanol: V water = 60 / 40) according to the material-liquid ratio of 1:40 (solid-liquid ratio unit g / mL), and then place Ultrasonic extraction was performed in a water bath at 40°C for 30 min, and the ultrasonic dispersion was cooled to room temperature, adjusted to pH = 3 with 1 mol / L hydrochloric acid solution, and left to stand for 4 h.

[0040] Then, the pH-adjusted ...

Embodiment 2

[0043] The water chestnut shell produced in Suqian, Jiangsu is crushed and passed through an 80-mesh sieve to obtain water chestnut shell powder with a mesh size greater than 80 mesh. Add 1.03 g of the water chestnut shell powder in the stainless steel ball mill tank, add 20 stainless steel ball mill beads with a diameter of 10 mm (ball mill filling rate 20.9%) and 0.15 g auxiliary agent (the auxiliary agent is sodium bicarbonate), and the ball mill time is 5 min , the milling speed is 100 rpm.

[0044] Weigh 0.53 g of the powder after ball milling, and the remaining follow-up operating conditions are the same as in Example 1 to obtain 0.12 g of the crude extract of the ethyl acetate layer, and calculate 1,2,3,6-tetra-O-galloyl-β-D-glucose The yield was 1.9%.

Embodiment 3

[0046] The water chestnut shell produced in Jiaxing, Zhejiang is crushed and passed through an 80-mesh sieve to obtain water chestnut shell powder with a mesh size greater than 80 mesh. Add 1.04 g of the water chestnut shell powder in the stainless steel ball mill tank, add 20 stainless steel ball mill beads with a diameter of 10 mm (ball mill filling rate 20.9%) and 0.15 g auxiliary agent (the auxiliary agent is sodium bicarbonate), and the ball mill time is 5 min , the milling speed is 100 rpm.

[0047] Weigh 0.51 g of the powder after ball milling, and the remaining follow-up operating conditions are the same as in Example 1 to obtain 0.11 g of the crude extract of the ethyl acetate layer, and calculate 1,2,3,6-tetra-O-galloyl-β-D-glucose The yield was 1.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com