Preparation method of SnS micron flower and application of SnS micron flower in magnesium battery

A micron flower and magnesium battery technology, applied in the field of electrochemical energy storage, can solve the problems of lack of high-capacity, long-cycle positive electrode materials, lack of electrolyte, etc., and achieve high discharge capacity, high theoretical specific capacity, and long cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of SnS microflowers:

[0028] (1) SnCl 4 1. Add thiourea into a certain amount of 1:4 ethylene glycol / water mixed solution at a molar ratio of 1:2.5, stir until dissolved, then add an appropriate amount of cetyl ammonium bromide, and stir for half an hour;

[0029] (2) Transfer the mixed solution to a polytetrafluoroethylene reactor and react at 160°C for 20 hours;

[0030] (3) After natural cooling, wash with water and ethanol several times respectively, and dry under vacuum at 60°C.

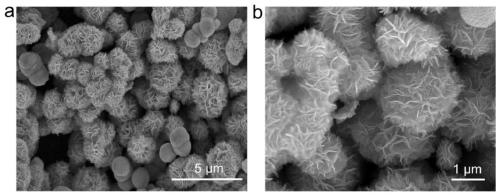

[0031] figure 1 A scanning electron microscope image (SEM) of the SnS is shown, and it can be seen from the figure that the SnS morphology is a microsphere.

Embodiment 2

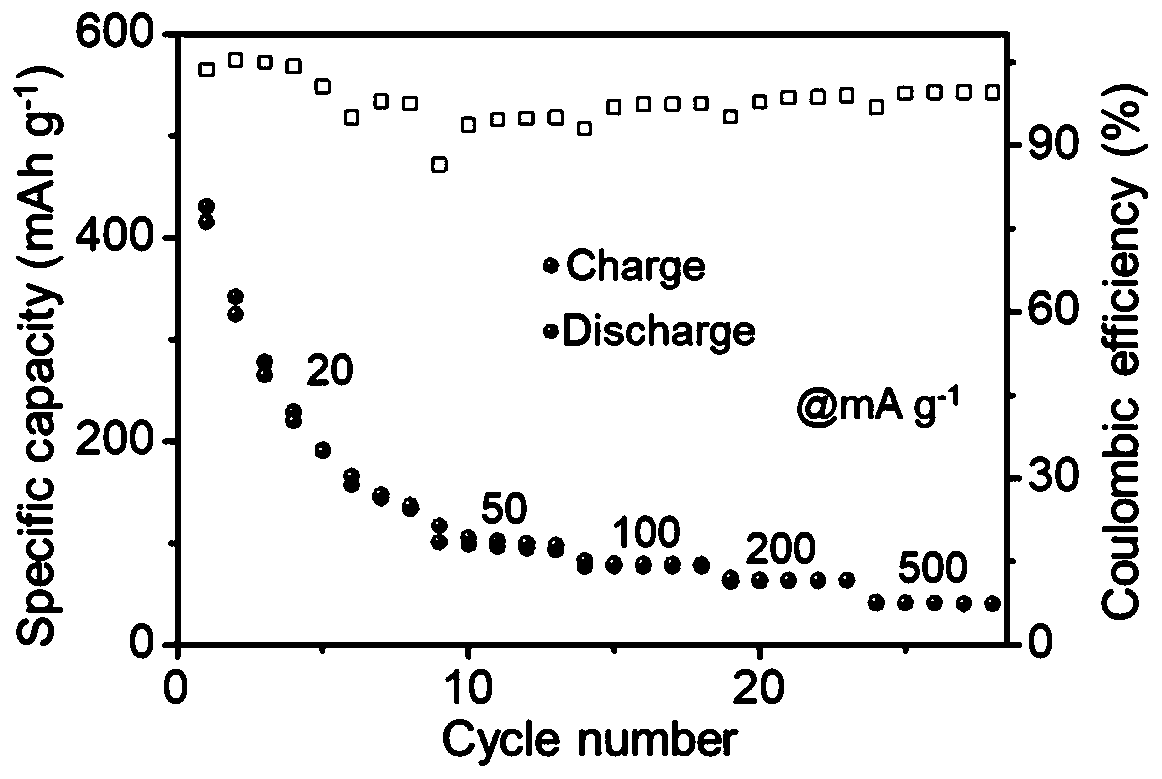

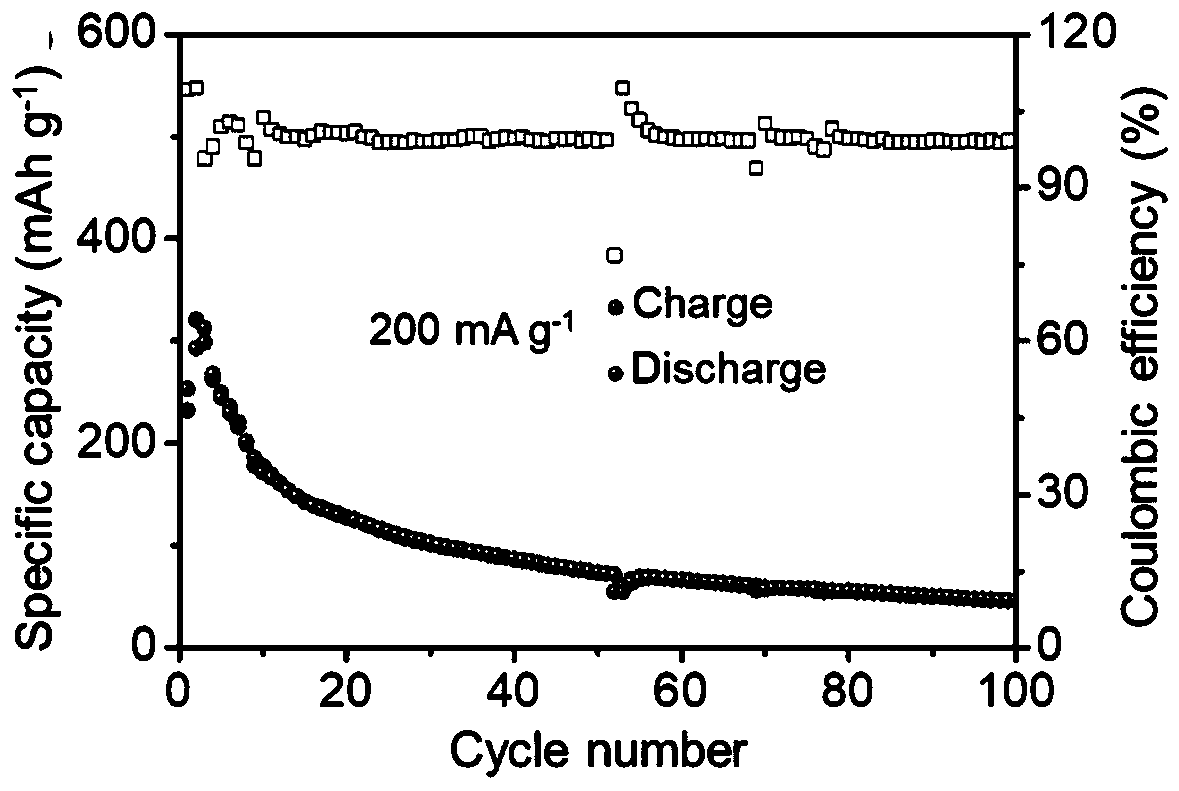

[0033] Electrochemical performance test:

[0034] The magnesium battery was assembled in an anhydrous and oxygen-filled argon glove box, and its electrochemical performance tests were completed in the Blue Electron Testing System (LAND). Specific steps are as follows:

[0035] (1) Grind the prepared SnS micron flowers, acetylene black and polytetrafluoroethylene according to the mass ratio of 7:2:1, then add an appropriate amount of N-methylpyrrolidone, stir into a homogenous slurry, and apply it on carbon paper Electrode sheet was made on it, and dried in vacuum at 60°C for 24 hours, and then cut into a disc with a diameter of 1.4cm, that is, the positive electrode;

[0036] (2) Polish the magnesium foil to silvery white with sandpaper, wash it with tetrahydrofuran, dry it naturally, and cut it into small discs, that is, the negative electrode;

[0037] (3) Open the glove box, and assemble the SnS positive electrode, magnesium foil negative electrode, glass fiber membrane a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com