Preparation method of artemisia scoparia volatile oil/epoxy resin composite material

An epoxy resin and composite material technology, which is applied in the field of polymer materials, can solve the problems of few types of natural antibacterial agents, less than ideal antibacterial effect, and low temperature resistance, and achieves long antibacterial time, sustainable development and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In parts by weight, 20 parts of epoxy resin (bisphenol A type epoxy resin) and 10 parts of toughening agent (liquid nitrile rubber) are added into the stirring tank for high-speed dispersion, vacuum defoaming, and the first component is obtained for subsequent use;

[0041] In parts by weight, add 0.5 parts of Artemisia annua volatile oil into 25 parts of curing agent (hexahydrophthalic anhydride), disperse and stir at a high speed in a stirring tank until dissolved, add 0.1 part of accelerator (2,4,6-three (two methylaminomethyl) phenol), vacuum defoaming, to obtain component B for subsequent use;

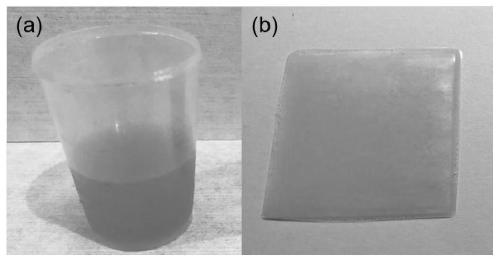

[0042] Mix components A and B evenly according to the weight ratio of 1:1, then put them into a vacuum oven for degassing, and obtain a uniform liquid such as figure 1 (a).

[0043] Pour the above mixture into a preheated mold and place it in a 180°C oven for curing for 1 hour to obtain a yellow Artemisia annua volatile oil / epoxy resin composite material, such as figure 1...

Embodiment 2

[0046] In parts by weight, 45 parts of epoxy resins (cycloaliphatic epoxy resins) are added into a stirred tank for high-speed dispersion, vacuum defoaming, to obtain component A for subsequent use;

[0047] In parts by weight, add 3 parts of Artemisia annua volatile oil into 50 parts of curing agent (ethylenediamine), disperse and stir at a high speed in the stirring tank until dissolved, add 0.5 parts of accelerator (2-ethyl-4-methyl imidazole), vacuum defoaming, to obtain component B for subsequent use;

[0048] Mix components A and B evenly in a weight ratio of 1:1, and then put them in a vacuum oven for degassing;

[0049] The above mixture was poured into a preheated mold, and placed in an oven at 160°C for 2 hours to cure to obtain the Artemisia annua volatile oil / epoxy resin composite material.

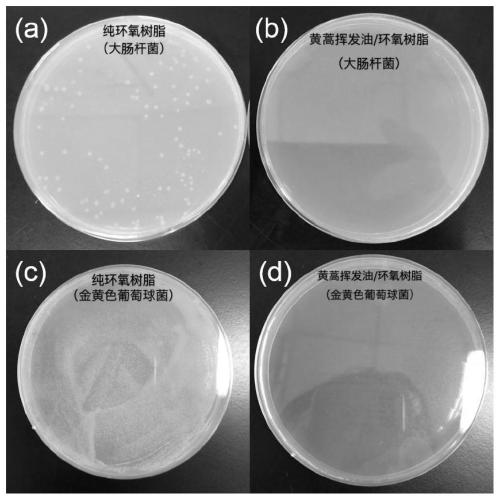

[0050] After testing, the curing temperature of the volatile oil of Artemisia annua volatile oil / epoxy resin composite material is 150.2°C, the antibacterial rate against Esc...

Embodiment 3

[0053] In parts by weight, add 40 parts of epoxy resin (hydroxymethyl bisphenol A type epoxy resin) and 7 parts of toughening agent (polyvinyl chloride) into the stirring tank for high-speed dispersion, vacuum defoaming, and obtain the first component for future use. ;

[0054] In parts by weight, add 8 parts of volatile oil of Artemisia annua obtained into 40 parts of curing agent (tetrahydrophthalic anhydride), disperse and stir at a high speed in the stirring tank until dissolved, add 0.2 parts of accelerator (N-p-chlorophenyl-N, N'-dimethylurea), vacuum defoaming, obtains component B for subsequent use;

[0055] Mix components A and B evenly according to the weight ratio of 1:1.5, and then put them into a vacuum oven for degassing;

[0056] The above mixture was poured into a preheated mold, placed in an oven at 170° C. for 1.5 h to cure, and a yellow Artemisia annua volatile oil / epoxy resin composite material was obtained.

[0057] After testing, the curing temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com