Process for producing high small peptide fermented bean meal by bacterial-enzyme co-fermentation

A technology of fermenting soybean meal and synergistic fermentation, applied in the direction of lactobacillus, food processing, bacteria used in food preparation, etc., can solve the problems of incomplete treatment of anti-nutritional factors, differences in the content of beneficial microorganisms, unstable product quality, etc., and achieve the goal of promoting Sustainable development, short fermentation cycle, beneficial to digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

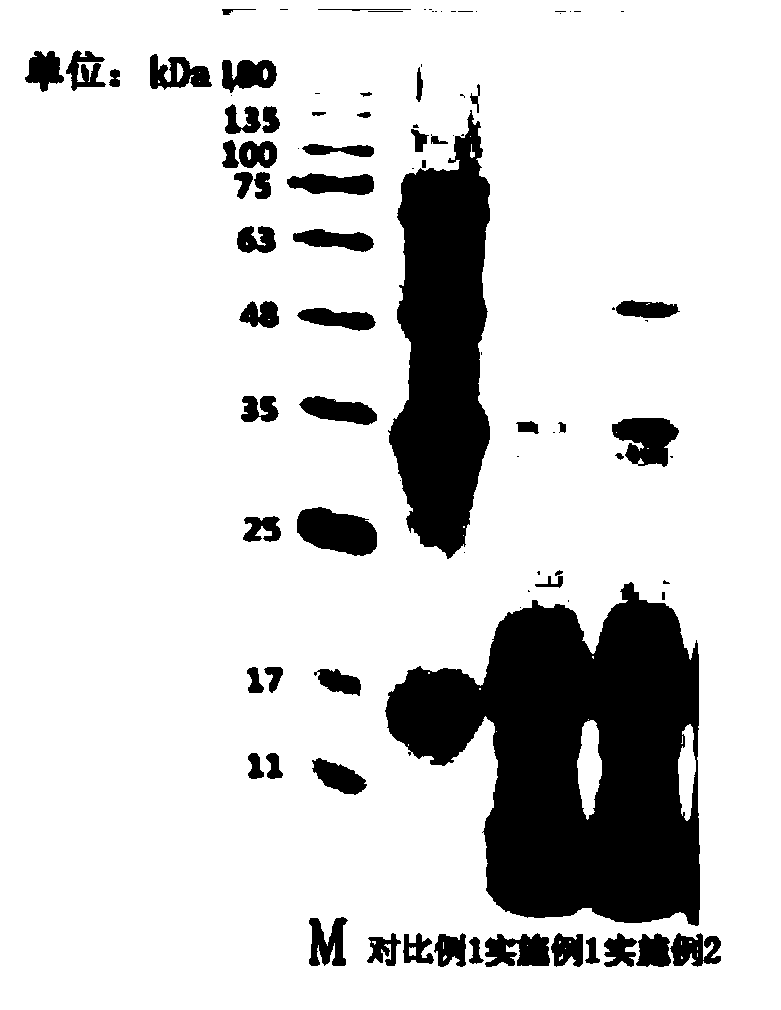

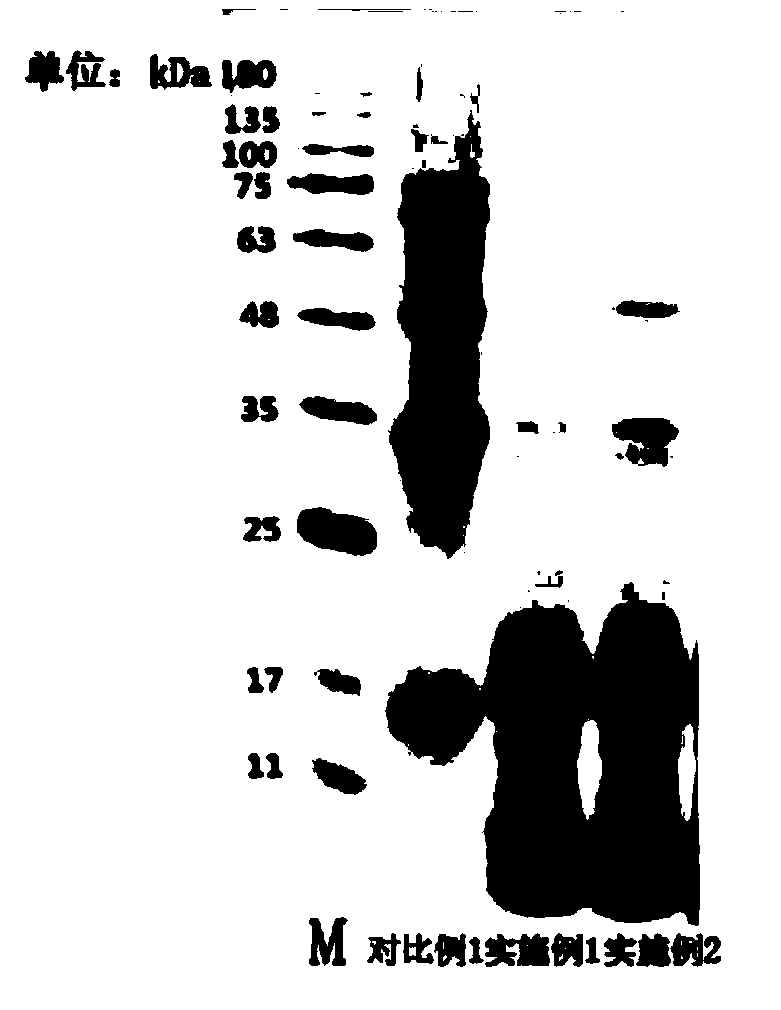

Image

Examples

Embodiment 1

[0027] A process for producing high-small peptide fermented soybean meal by bacteria-enzyme cooperative fermentation, comprising the following steps:

[0028] (1) By weight percentage, 96% soybean meal, 2% rice bran powder and 2% bran are uniformly mixed to obtain raw materials; wherein the protein content of soybean meal is 46%;

[0029] (2) Add compound bacterial agent and compound enzyme preparation to purified water, then add glucose, adjust the pH value to 6.2-6.5, mix and stir for 15 minutes, and obtain activated bacterial liquid; wherein compound bacterial agent, compound enzyme preparation, purified water, The weight ratio of glucose is 1:0.5:100:1; the amount of Saccharomyces cerevisiae in the compound microbial agent is 2.4×10 10 cfu / g, the amount of Lactobacillus plantarum is 5.0×10 9 cfu / mL, the amount of Enterococcus faecium is 5.5×10 9 cfu / g, the amount of Bacillus subtilis is 1.5×10 9 cfu / g; the amount of neutral protease in the compound enzyme preparation is...

Embodiment 2

[0033] A process for producing high-small peptide fermented soybean meal by bacteria-enzyme cooperative fermentation, comprising the following steps:

[0034] (1) By weight percentage, 95% soybean meal, 2% rice bran powder, and 3% bran are uniformly mixed to obtain raw materials; wherein the protein content of soybean meal is 46%;

[0035] (2) Add compound bacterial agent and compound enzyme preparation to purified water, then add glucose, adjust the pH value to 6.2-6.5, mix and stir for 15 minutes, and obtain activated bacterial liquid; wherein compound bacterial agent, compound enzyme preparation, purified water, The weight ratio of glucose is 2:0.5:100:1.5; the amount of Saccharomyces cerevisiae in the compound bacterial agent is 2.2×10 10 cfu / g, the amount of Lactobacillus plantarum is 5.5×10 9 cfu / mL, the amount of Enterococcus faecium is 6.0×10 9 cfu / g, the amount of Bacillus subtilis is 2.0×10 9 cfu / g; the amount of neutral protease in the compound enzyme preparation...

Embodiment 3

[0039] A process for producing high-small peptide fermented soybean meal by bacteria-enzyme cooperative fermentation, comprising the following steps:

[0040] (1) By weight percentage, 97% of soybean meal, 1% of rice bran powder, and 2% of bran are uniformly mixed to obtain raw materials; wherein the protein content of soybean meal is 46%;

[0041] (2) Add the compound bacterial agent and compound enzyme preparation into purified water, then add glucose, adjust the pH value to 6.2-6.5, mix and stir for 30 minutes, and obtain the activated bacterial liquid; wherein the compound bacterial agent, compound enzyme preparation, purified water, The weight ratio of glucose is 2:0.5:100:1; the amount of Saccharomyces cerevisiae in the compound microbial agent is 2.4×10 10 cfu / g, the amount of Lactobacillus plantarum is 6.0×10 9 cfu / mL, the amount of Enterococcus faecium is 5.0×10 9 cfu / g, the amount of Bacillus subtilis is 2.0×10 9 cfu / g; the amount of neutral protease in the compound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com