Mild dredging agent for kitchen pipelines

A technology of dredging agent and pipeline, which is applied in the direction of detergent compounding agent, detergent composition, chemical instrument and method, etc., which can solve the problems of pipeline damage, achieve the effects of hindering the formation of blockage, reducing the effect of stacking and improving the dredging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

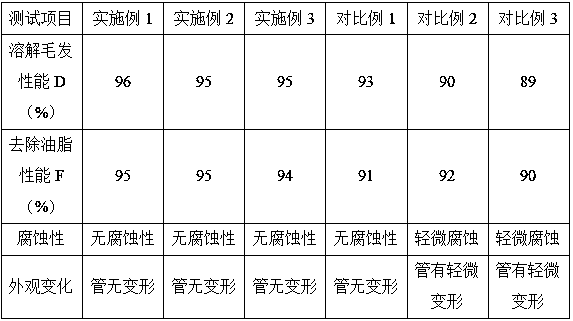

Examples

preparation example Construction

[0031] The preparation method of composite dredging base material comprises the steps:

[0032] (1) At 25~35°C, in parts by weight, take 8~15 parts of ferrous nitrate, 15~30 parts of ferric nitrate, and 80~100 parts of water in the reactor and mix them with 15% sodium hydroxide Adjust the pH of the solution to 8.0-8.5 to obtain a mixed solution. Take the mixed solution and add lecithin with a mass of 3-7% of the mixed solution and Tween-80 with a mass of 5-8% of the mixed solution. Stir and mix at a constant temperature for 45-60 minutes, and keep it for 2-4 hours. , to obtain the aged liquid, take the aged liquid at 75~80°C, concentrate under reduced pressure to 25~40% of the original volume to obtain the concentrated liquid, take the concentrated liquid and transport it to the spray dryer, when the inlet air temperature is 90~100 ℃, and the air outlet temperature is 75-85 ℃, spray granulation to obtain hollow nano-beads;

[0033] (2) Mix crushed ice, additives and water wit...

Embodiment 1

[0041] Auxiliary: Mix microcrystalline paraffin, magnesium stearate, and castor oil at a mass ratio of 1:2:1 to obtain the adjuvant.

[0042] Selenium-containing reagent: Mix diphenylselenide and diphenylselenide in a mass ratio of 4:3 to obtain a selenium-containing reagent.

[0043] Fermentation material: by mass parts, take 6 parts of vermicompost, 5 parts of beef extract, 7 parts of glucose, 0.1 part of NaH 2 PO 4 , 2 parts of Lactobacillus bulgaricus powder, 3 parts of casein, and 300 parts of water were mixed in a fermenter, fermented and cultured on a shaking table at 180r / min at 28°C for 3 days, then sterilized at 100°C for 12min, filtered, and the filtrate was collected. That is, the fermented material is obtained.

[0044] Foaming agent: Mix fatty alcohol polyoxyethylene ether sodium sulfate and petroleum ether in a mass ratio of 3:1 to obtain a foaming agent.

[0045] Surfactant: Mix dodecyl dimethyl betaine and sodium secondary alkylbenzene sulfonate at a mass r...

Embodiment 2

[0058] Auxiliary: Mix microcrystalline paraffin, magnesium stearate, and castor oil in a mass ratio of 1:3:1 to obtain the adjuvant.

[0059] Selenium-containing reagent: Mix diphenylselenide and diphenylselenide at a mass ratio of 6:3 to obtain a selenium-containing reagent.

[0060] Fermentation material: in parts by mass, take 8 parts of vermicompost, 6 parts of beef extract, 10 parts of glucose, 0.3 part of NaH 2 PO 4 , 3 parts of Lactobacillus bulgaricus powder, 5 parts of casein, and 400 parts of water were mixed in a fermenter, fermented and cultured on a shaking table at 200 r / min at 30°C for 4 days, and sterilized at 105°C for 16 minutes, filtered, and the filtrate was collected. That is, the fermented material is obtained.

[0061] Foaming agent: Mix fatty alcohol polyoxyethylene ether sodium sulfate and petroleum ether at a mass ratio of 5:1 to obtain a foaming agent.

[0062] Surfactant: Mix dodecyl dimethyl betaine and sodium secondary alkylbenzene sulfonate at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com