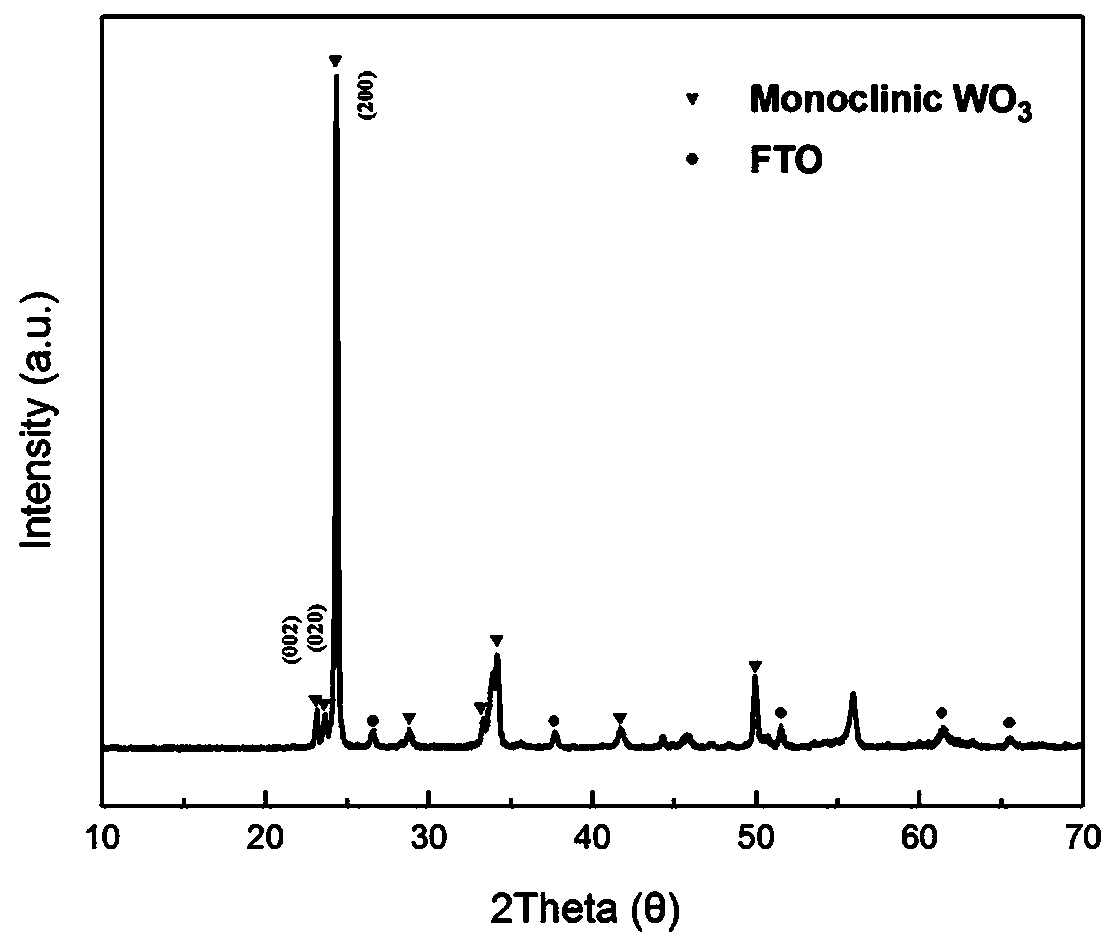

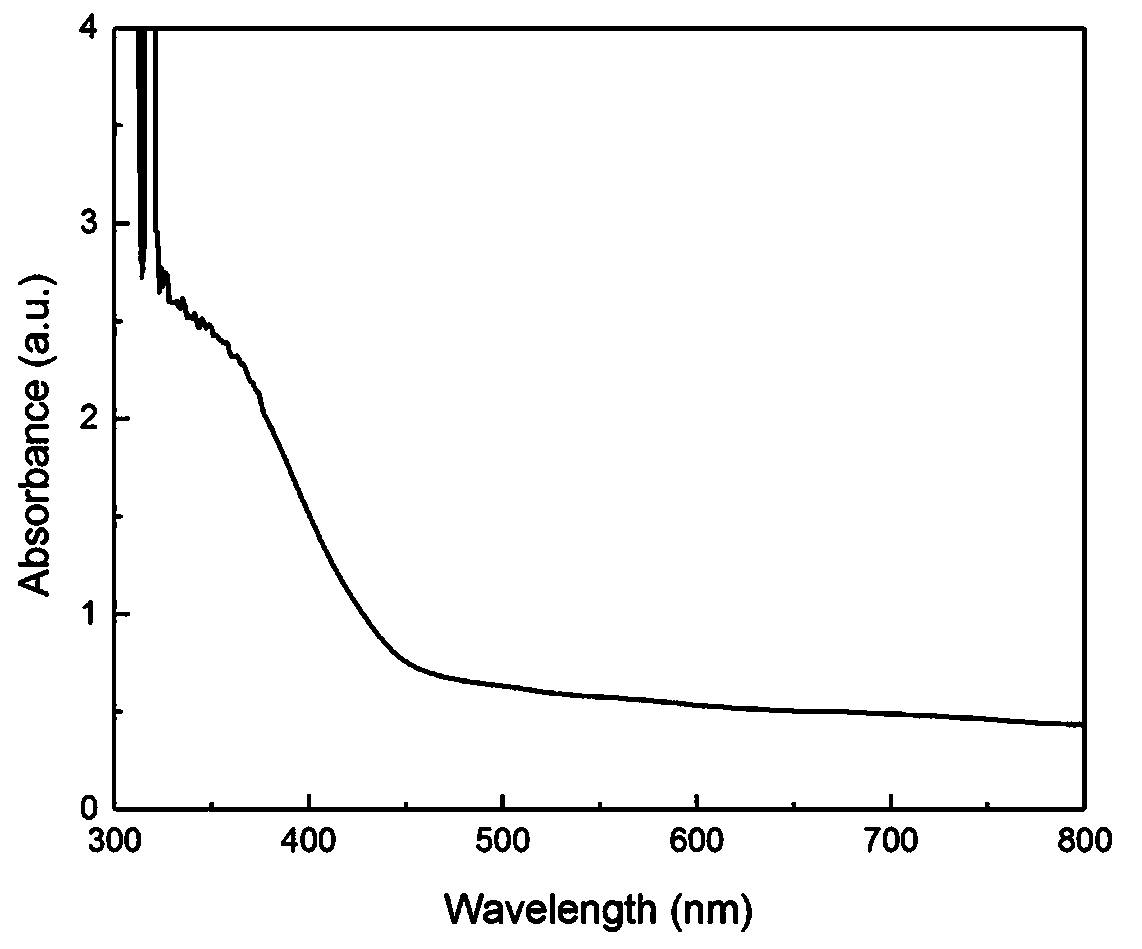

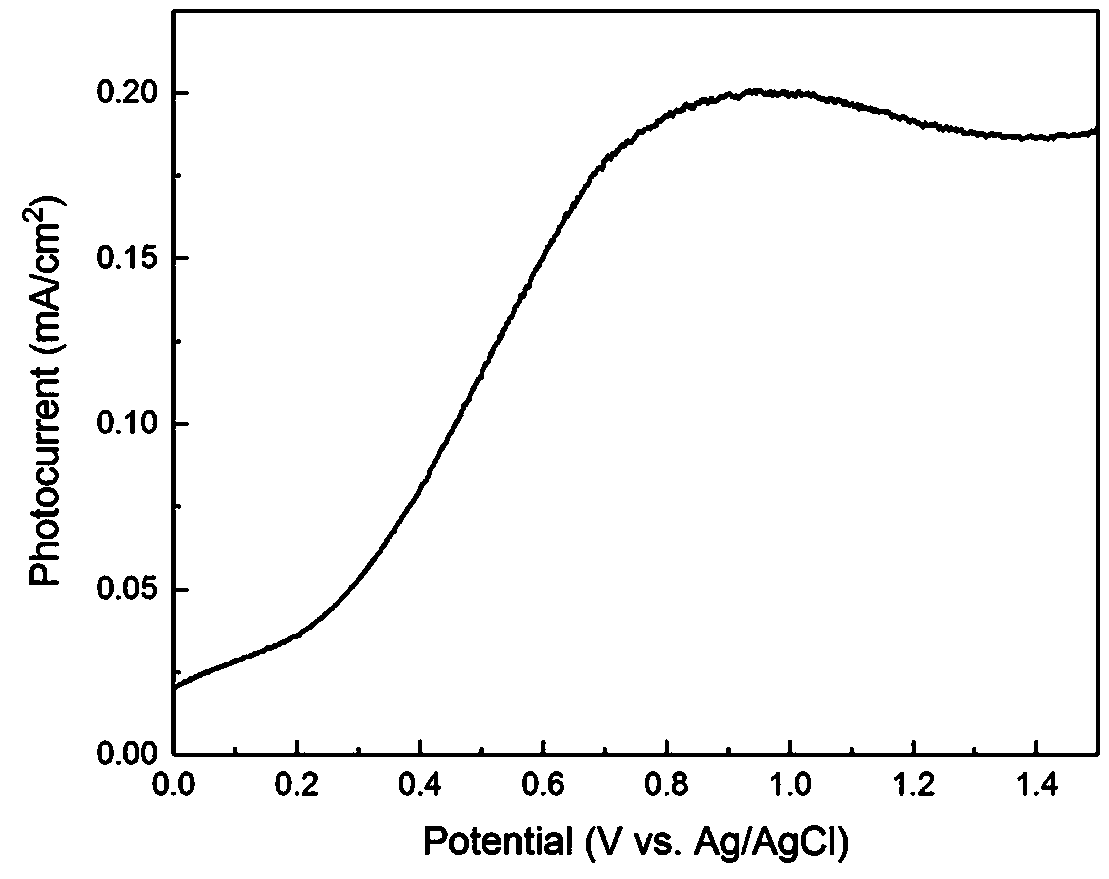

Layered tungsten trioxide photoelectrode material and preparation method thereof

A technology of tungsten trioxide and photoelectrode, which is applied in the direction of tungsten oxide/tungsten hydroxide, circuits, electrical components, etc., to achieve the effects of improving transmission efficiency, accelerating conduction, and simple and easy operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Pretreatment of FTO: FTO was ultrasonically cleaned with acetone, a mixed solution of isopropanol and water (volume ratio 1:1:1), and deionized water for 30 min, respectively, and dried at 70 °C for later use.

[0024] (2) Weigh 330 mg of sodium tungstate, add it to 20 mL of deionized water, stir at room temperature for 15 min, add 0.5 mL of hydrogen peroxide solution (mass fraction is 30 %) under stirring condition, mix well, Stir at room temperature for 10 min; then add 0.4 mL of hydrochloric acid solution (36% mass fraction) to the mixed solution, white smoke comes out, stir at room temperature for 10 min; then add 0.05 g of oxalic acid to the mixed solution, Stir at room temperature for 15 min; finally add 10 mL of absolute ethanol and stir at room temperature for 15 min to obtain a clear and transparent precursor solution.

[0025] (3) Transfer the prepared precursor liquid to the polytetrafluoroethylene reactor, and immerse two pieces of FTO in the precursor l...

Embodiment 2

[0033](1) Pretreatment of FTO: FTO was ultrasonically cleaned with acetone, a mixed solution of isopropanol and water (volume ratio 1:1:1), and deionized water for 30 min, respectively, and dried at 70 °C for later use.

[0034] (2) Weigh 250 mg of tungstic acid, add it to 19 mL of deionized water, stir at room temperature for 10 min, add 1.0 mL of hydrogen peroxide solution (mass fraction: 30 %) under stirring condition, mix well, and Stir at room temperature for 10 min; then add 1.4 mL of hydrochloric acid solution (mass fraction 36 %) to the mixed solution, white smoke comes out, stir at room temperature for 10 min; then add 62 mg of oxalic acid to the mixed solution, Stir at room temperature for 20 min; finally add 15 mL of absolute ethanol and stir at room temperature for 10 min to obtain a light yellow precursor solution.

[0035] (3) Transfer the prepared precursor liquid to the polytetrafluoroethylene reactor, and immerse two pieces of FTO in the precursor liquid symme...

Embodiment 3

[0039] (1) Pretreatment of FTO: FTO was ultrasonically cleaned with acetone, a mixed solution of isopropanol and water (volume ratio 1:1:1), and deionized water for 30 min, respectively, and dried at 70 °C for later use.

[0040] (2) Weigh 330 mg of sodium tungstate, add it to 20 mL of deionized water, stir at room temperature for 20 minutes, add 0.5 mL of hydrogen peroxide solution (mass fraction: 30%) under stirring conditions, mix well, and Stir at room temperature for 10 min; then add 0.35 mL of hydrochloric acid solution (mass fraction 36 %) to the mixed solution, white smoke comes out, stir at room temperature for 10 min; then add 15 mg of oxalic acid to the mixed solution, Stir at room temperature for 15 min; finally add 10 mL of absolute ethanol and stir at room temperature for 10 min to obtain a clear and transparent precursor solution.

[0041] (3) Transfer the prepared precursor liquid to the polytetrafluoroethylene reactor, and immerse two pieces of FTO in the prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com