Lithium battery, lithium battery diaphragm and preparation method of lithium battery diaphragm

A technology of lithium battery diaphragm and vinylidene fluoride, which is applied in the direction of lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of low tensile strength, impossibility of real application, poor degradability and other problems, and achieve improvement Electrochemical performance and safety performance, good biodegradation performance, accelerated fracture and degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

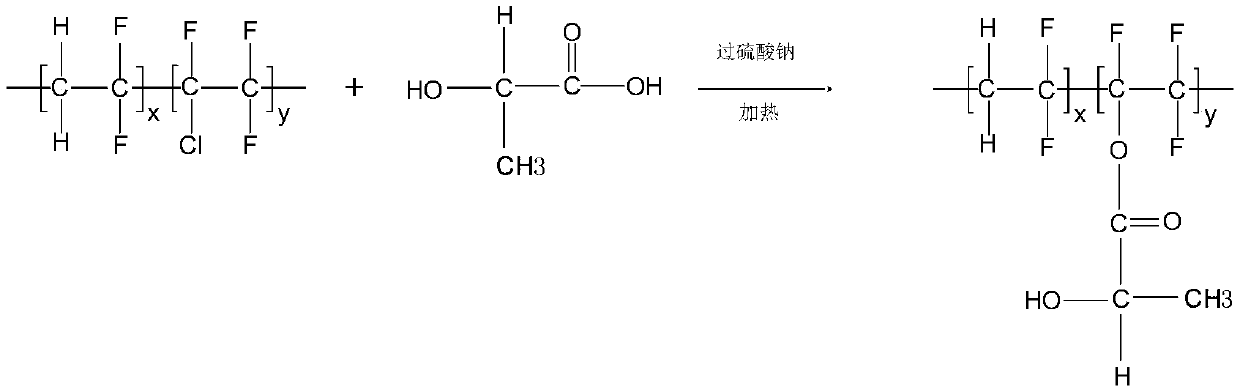

[0030] In parts by mass, add 10 parts of poly(vinylidene fluoride-chlorotrifluoroethylene) and 2 parts of lactic acid to 50 parts of organic solvent, stir to dissolve, add 0.5 parts of sodium persulfate and 2 parts of potassium acid, and then stir Reaction; the specific reaction formula is:

[0031]

[0032] After the reaction is finished, the reaction mixture is added to an alkaline aqueous solution, stirred and precipitated, filtered, washed, and dried to obtain the target product poly(vinylidene fluoride-chlorotrifluoroethylene-lactic acid) copolymer resin;

[0033] Add 15 parts by mass of poly(vinylidene fluoride-chlorotrifluoroethylene-lactic acid) copolymer resin, 8 parts by mass of polyvinylpyrrolidone and 2 parts by mass of polymethyl methacrylate to 75 parts of organic solvent, at 50 Stir and dissolve at ℃; then filter through a sieve and stand for defoaming, then scrape coat it on a coating machine to form a uniform film; finally put the coated film into an oven, ...

Embodiment 2

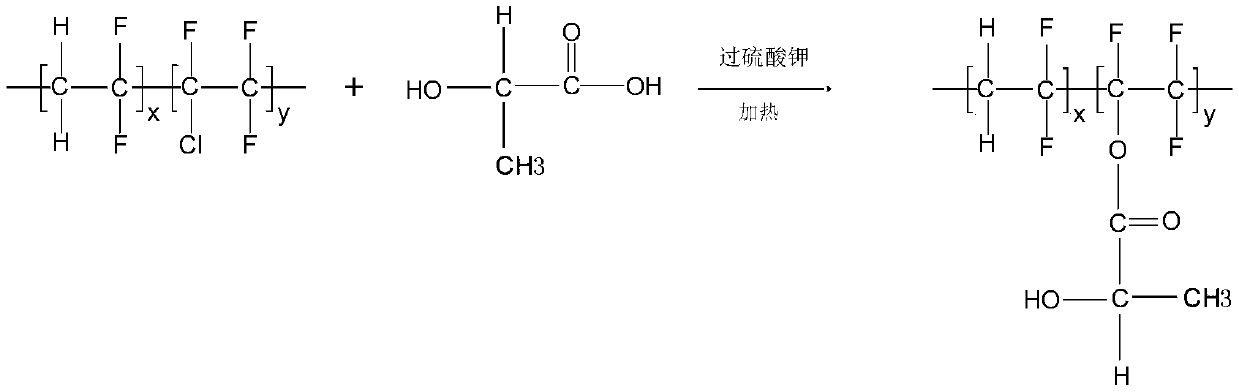

[0036] In parts by mass, add 11 parts of poly(vinylidene fluoride-chlorotrifluoroethylene) and 3 parts of lactic acid to 60 parts of N,N-dimethylacetamide, stir to dissolve, add 1 part of potassium persulfate and 4 parts of Potassium acid, then stirring reaction; Concrete reaction formula is:

[0037]

[0038] After the reaction is finished, the reaction mixture is added to an alkaline aqueous solution, stirred and precipitated, filtered, washed, and dried to obtain the target product poly(vinylidene fluoride-chlorotrifluoroethylene-lactic acid) copolymer resin;

[0039] Add 12 parts by mass of poly(vinylidene fluoride-chlorotrifluoroethylene-lactic acid) copolymer resin, 6 parts by mass of polyethylene glycol and 4 parts by mass of polyvinyl alcohol into 78 parts of N,N-dimethylacetamide, in Stir and dissolve at 60°C; then filter through a sieve and stand for defoaming, then scrape coat it on a coating machine to form a uniform film; finally put the coated film into an ove...

Embodiment 3

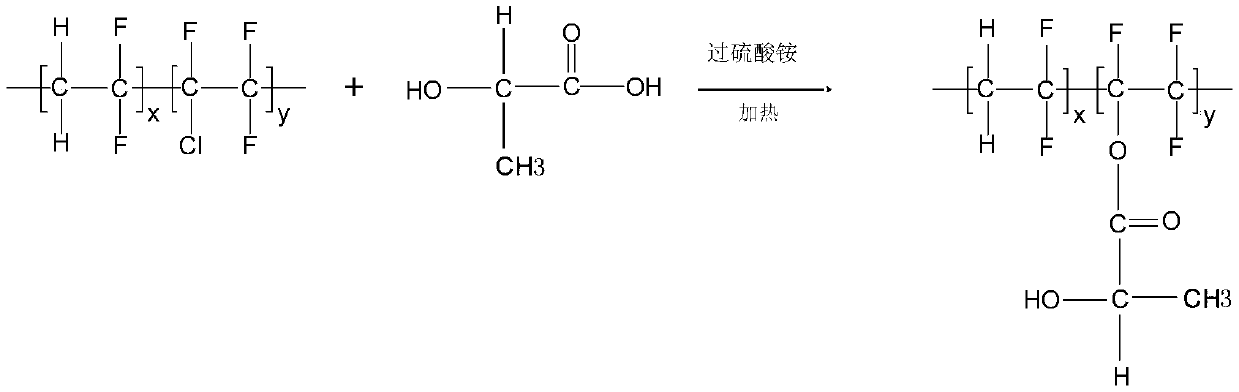

[0041]In parts by mass, 12 parts of poly(vinylidene fluoride-chlorotrifluoroethylene) and 4 parts of lactic acid are added to 70 parts of tetrahydrofuran, stirred to dissolve, 2 parts of sodium persulfate and 6 parts of ammonium formate are added, and the reaction is stirred The specific reaction formula is as in Example 1. After the reaction finishes, the reaction mixture is added to the alkaline aqueous solution to stir and precipitate, filter, wash, and dry to obtain the target product poly(vinylidene fluoride-chlorotrifluoroethylene-lactic acid) copolymer resin ;

[0042] Add 10 parts by mass of poly(vinylidene fluoride-chlorotrifluoroethylene-lactic acid) copolymer resin, 8 parts by mass of polypropylene glycol and 3 parts by mass of chitosan to 60 parts of tetrahydrofuran, stir and dissolve at 70°C; then pass through a sieve After screen filtration and static defoaming, it is scraped on a coating machine to form a uniform film; finally, the coated film is placed in an ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com