Water-soluble self-healing binding agent, preparation method thereof and lithium ion battery

A technology of lithium-ion batteries and binders, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of silicon anode materials being close to each other, and achieve the effects of mild conditions, improved cycle performance rate performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In one embodiment, the preparation method of the water-soluble self-healing adhesive at least includes the following steps:

[0034] Step S01. Under an inert atmosphere, 2-(6-isocyanate hexylamine amide)-6-methyl-4-[H]-pyrimidinone, hydroxyethyl acrylate, catalyst and the first organic solvent are mixed and refluxed ;

[0035] Step S02. Adding a precipitating agent to the reaction solution obtained in step S01 to obtain a precipitate;

[0036] Step S03. Under an inert atmosphere, dissolve the precipitate and tert-butyl acrylate in a second organic solvent to obtain a mixed solution, and add an initiator to the mixed solution to cause free radical polymerization to obtain a polymerization thing;

[0037] Step S04. Using a third organic solvent to hydrolyze the polymer to obtain the water-soluble self-healing adhesive as described above.

[0038] Next, the preparation method will be further explained.

[0039] The inert gas involved in the inert atmosphere conditions ...

Embodiment 1

[0068] A preparation method of a water-soluble self-healing adhesive, comprising the following steps:

[0069] (1) Dissolve 1.5g of 2-(6-isocyanate hexylamine amide)-6-methyl-4-[H]-pyrimidinone and 1.0g of hydroxyethyl acrylate in 50mL of chloroform, add 0.05g of dilauric acid di Butyltin, reacted at 40°C for 12h under nitrogen protection;

[0070] (2) Cool the reaction solution in step (1) to room temperature, add 200mL of ether to precipitate the product, filter under reduced pressure and vacuum dry at 40°C to obtain the small molecule ureidopyrimidinone hexylaminoethyl acrylate (UPy -HDI-HEA);

[0071] (3) Dissolve 0.4g of monomer UPy-HDI-HEA and 8.0g of tert-butyl acrylate in 30mL of dioxane solvent, add 10mg of AIBN initiator, and react at 70°C for 12h under nitrogen protection to obtain PtBA-UPy;

[0072] (4) Hydrolyze the obtained polymer PtBA-UPy solution with 100mL trifluoroacetic acid, hydrolyze for 24h, evaporate the solvent and trifluoroacetic acid to dryness und...

Embodiment 2

[0081] A preparation method of a water-soluble self-healing adhesive, comprising the following steps:

[0082] (1) Dissolve 2.0g of 2-(6-isocyanate hexylamine amide)-6-methyl-4-[H]-pyrimidinone and 1.0g of hydroxyethyl acrylate in 60mL of chloroform, add 0.15g of triethylamine, Reaction at 60°C for 15h under nitrogen protection;

[0083] (2) Cool the reaction solution in step (1) to room temperature, add 250 mL of ether to precipitate the product, filter under reduced pressure and vacuum dry at 50°C to obtain the small molecule ureidopyrimidinone hexylaminoethyl acrylate (UPy -HDI-HEA);

[0084] (3) Dissolve 0.4g of monomer UPy-HDI-HEA and 9.0g of tert-butyl acrylate in 50mL of dioxane solvent, add 15mg of BPO initiator, and react at 70°C for 12h under nitrogen protection to obtain PtBA-UPy;

[0085] (4) The obtained polymer PtBA-UPy solution was hydrolyzed with 90 mL of trifluoroacetic acid for 34 hours, the solvent and trifluoroacetic acid were rotary evaporated to dryness...

PUM

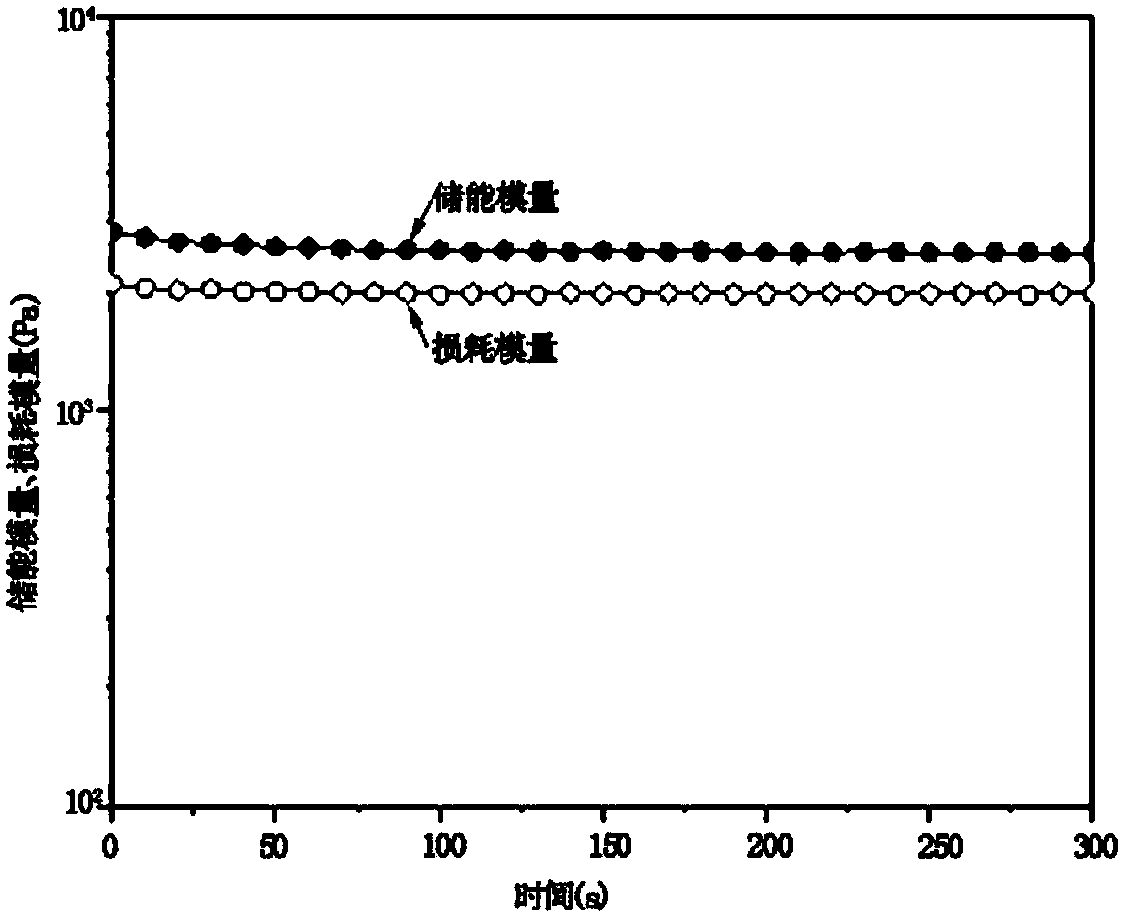

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com