Method for preparing betamethasone intermediate

A technology of betamethasone and bacteria strains, applied in the field of steroid biopharmaceuticals, can solve the problems of low dosage of recombinant strains, chemical synthesis pollution, and many by-products, and achieve the risk of increasing impurities, abundant sources, and cheap prices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Arthrobacter simplex CPCC 140451 was used as the transformed strain.

[0065] (1) Strain slant culture process: use a 500mL eggplant-shaped bottle, according to the following ratio: glucose 13g / L, yeast extract 16g / L, agar 18g / L, pH7.0-8.0 to prepare slant medium, each eggplant-shaped After sterilizing 100mL of bottled liquid at 121°C for 30 minutes, set up the slope, and place it in a 32°C incubator for 2 days after the slope solidified and formed. After culturing at 32°C for 2 days, the eggplant-shaped bottles were collected and placed in a refrigerator at 4°C until use.

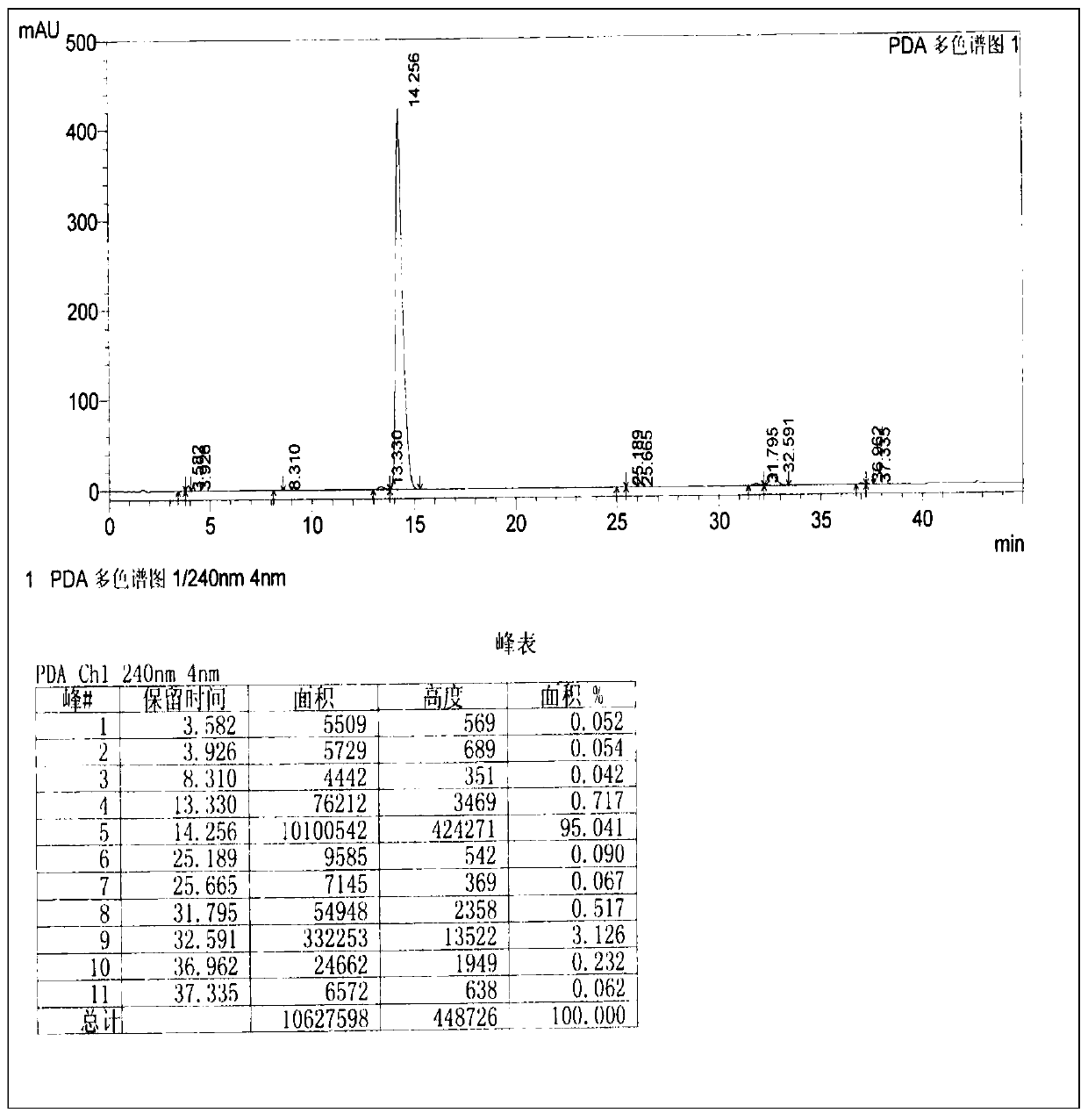

[0066] (2) Strain shake flask culture process: use 500mL shake flask, according to the following ratio: glucose 11.8g / L, corn steep liquor 6g / L, peptone 8g / L, KH 2 PO 4 4g / L, pH7.0-8.0 to prepare shake flask seed medium and fermentation transformation medium, each shake flask liquid 100mL, in which 1.0g / L compound I was added as induction before the fermentation transformation medium was sterilize...

Embodiment 2

[0068] Embodiment 2: Take Arthrobacter simplex CPCC 140451 as the transformation strain

[0069] (1) Strain slant culture and shake flask culture process: same as Example 1, the difference is that 1.5 g / L compound I was added as induction before the fermentation transformation medium was sterilized.

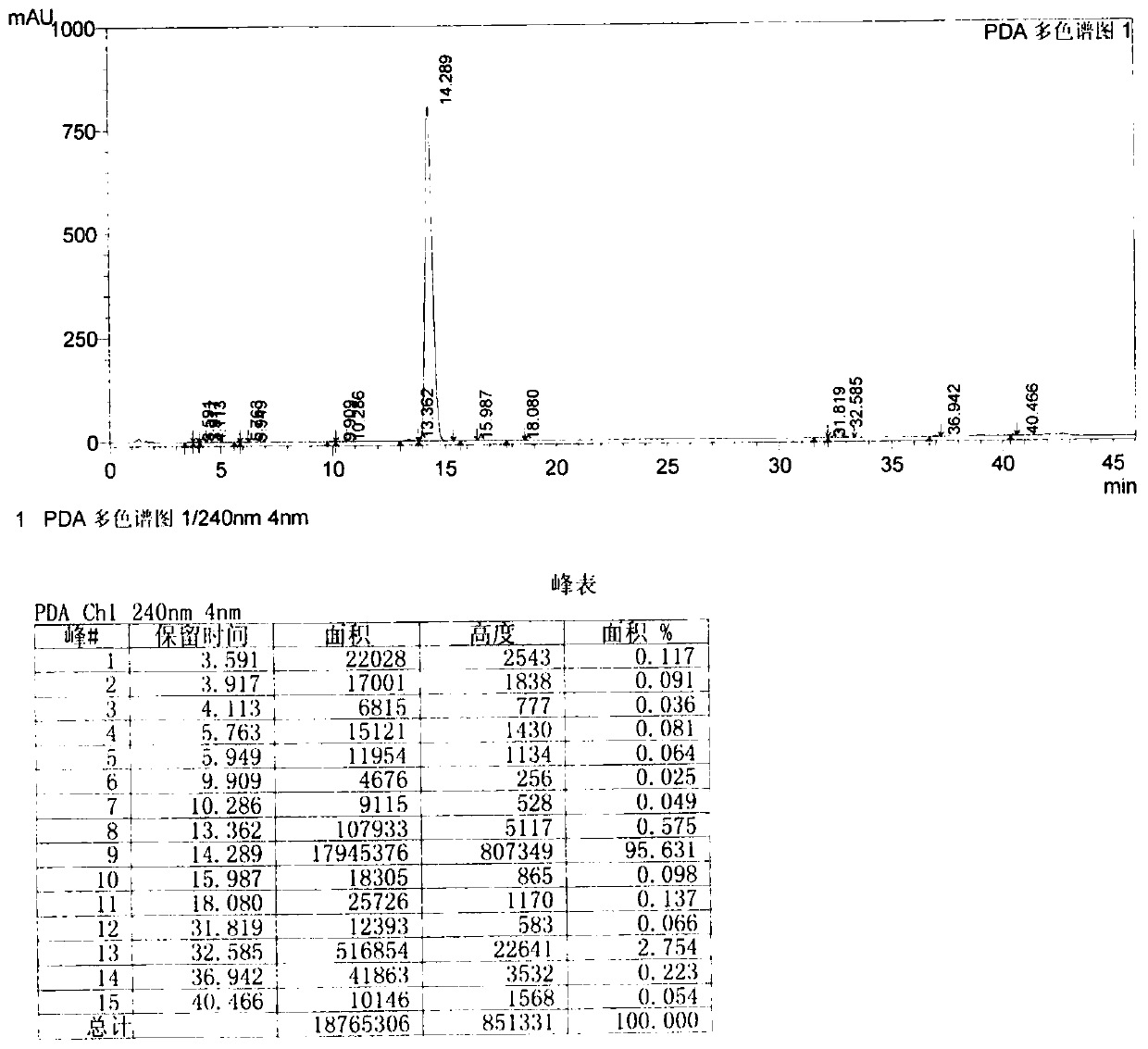

[0070] (2) Feed conversion process: add 10% ammonia water to the cultured 100mL fermentation broth, adjust the pH value to 9.5, weigh 6g of compound I, put it into a shaker flask, add 0.1% DMF (V / V), shake well Afterwards, the transformation was carried out at 34°C and 220rpm for 70 hours. After the transformation was completed, the temperature was raised to 70°C to terminate the reaction. Take 1mL of the transformation solution, add 20mL of acetone and sonicate it for 30min, and perform HPLC analysis after centrifugation. The conversion rate was 93.136%.

Embodiment 3

[0071] Embodiment 3: Take Arthrobacter simplex CPCC 140451 as the transformation strain

[0072] (1) Strain slant culture and shake flask culture process: same as Example 1, the difference is that 2.0 g / L compound I was added as induction before the fermentation transformation medium was sterilized.

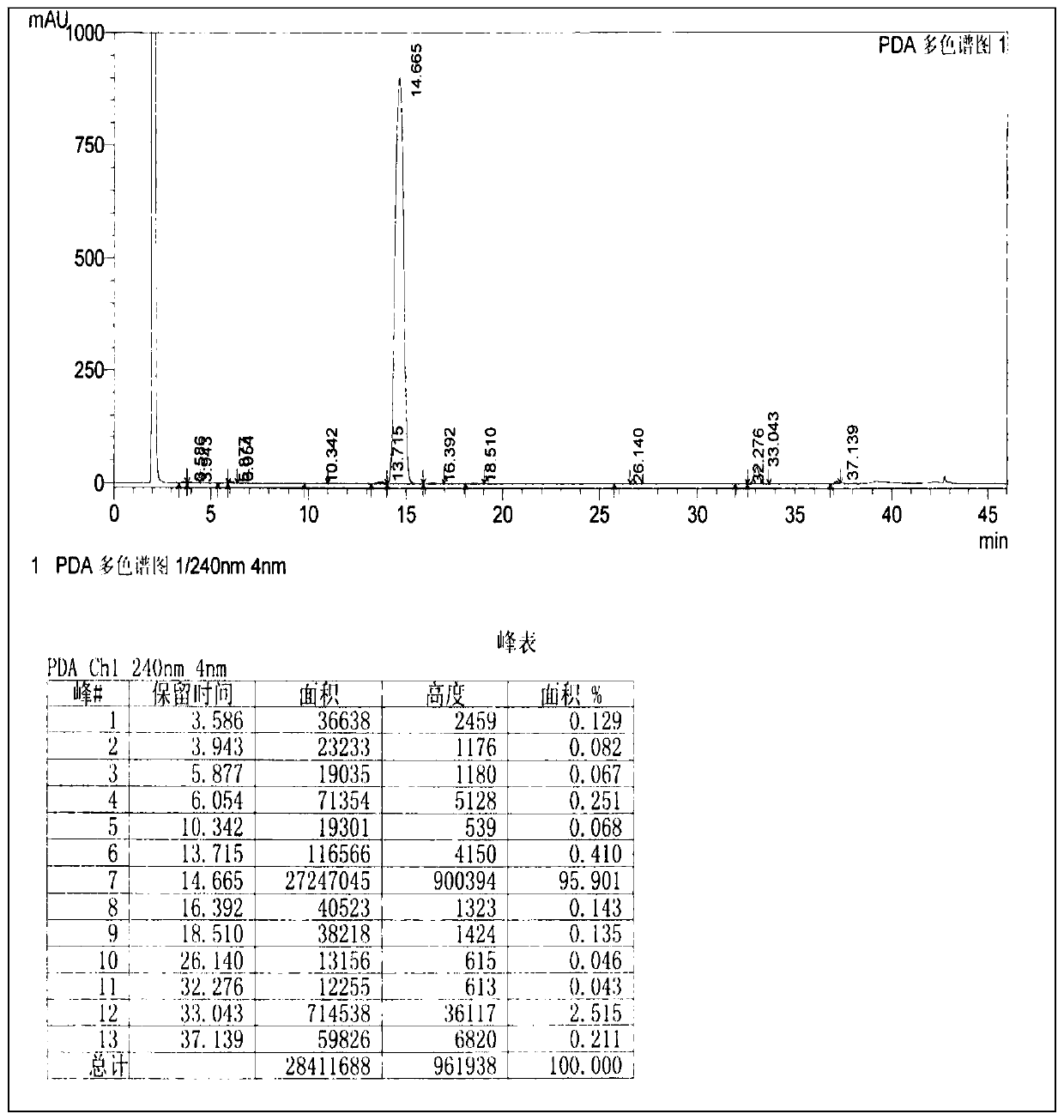

[0073] (2) Feed conversion process: add 15% aqueous sodium hydroxide solution to the cultured 100mL fermentation broth, adjust the pH value to 10.0, weigh 5g of compound I, put it into a shaker flask, add 0.1% DMSO (V / V) After shaking well, transform at 32°C transformation temperature and 220rpm rotation speed for 65 hours. After the transformation is completed, raise the temperature to 80°C to terminate the reaction. Take 1mL transformation solution, add 20mL acetone and sonicate for 30min, and perform HPLC analysis after centrifugation. The transformation rate is 94.632%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com