Control method for sediment ineutrophic drainage basins

A technology of eutrophication and control method, applied in the field of environmental management, can solve the problems of reducing the self-purification capacity of river and lake water, odor of water, poor adsorption capacity, etc. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

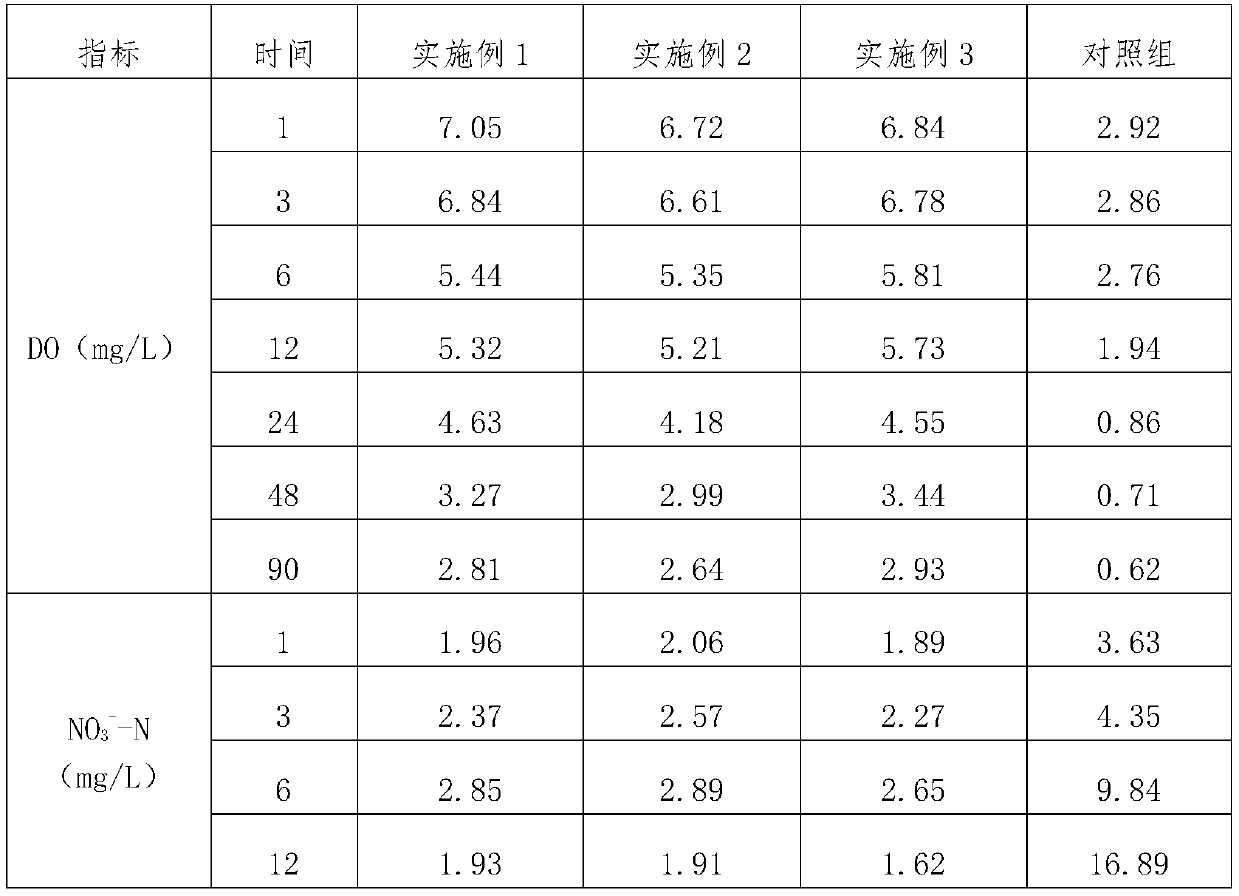

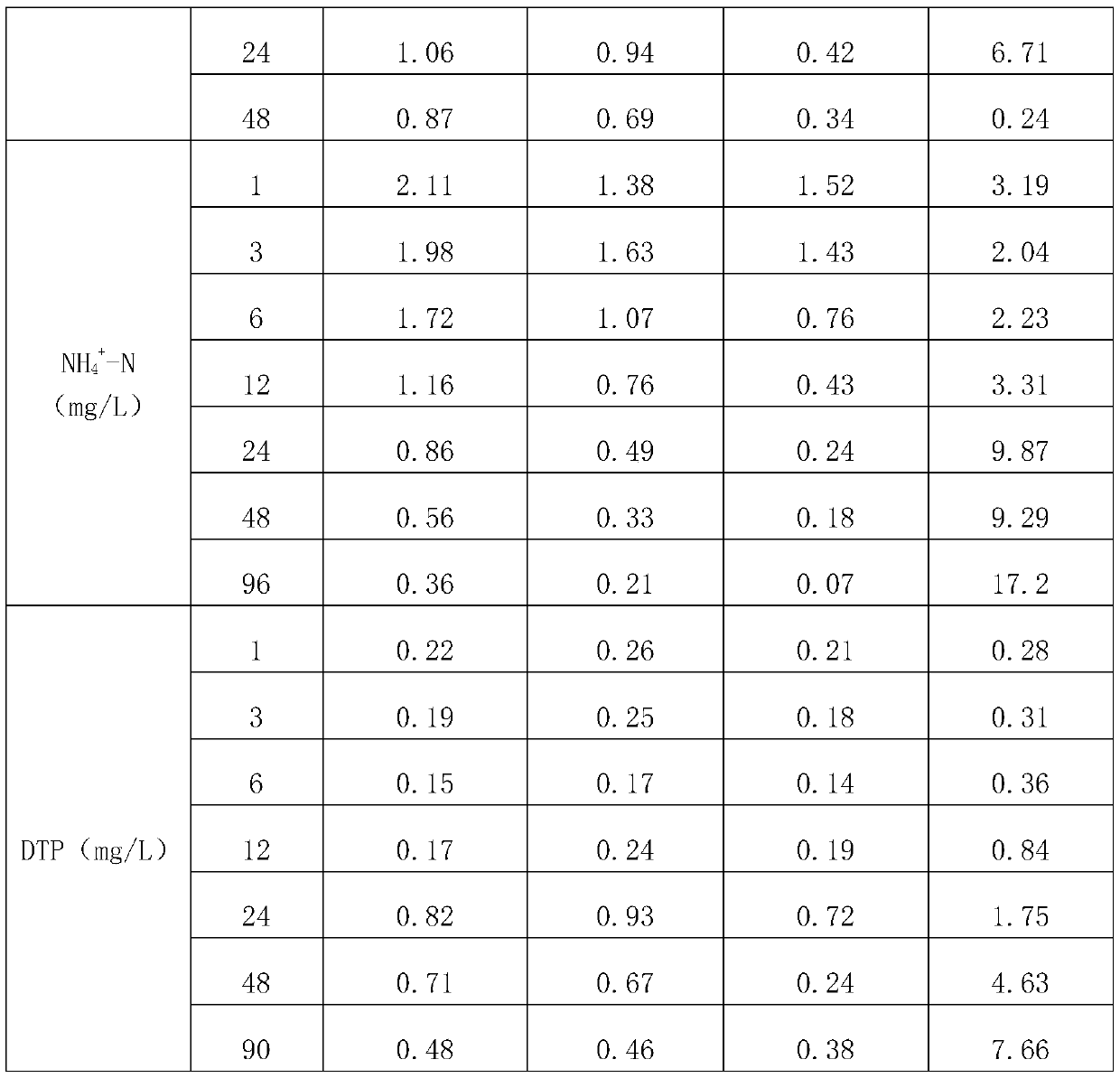

Embodiment 1

[0022] A method for controlling sediment in a eutrophic watershed, comprising the following steps:

[0023] (1) Modification: Prepare an acid solution with a concentration of 0.1 mol / L, mix it with bentonite, stir evenly in a mixer, and control the internal temperature of the mixer to 60°C, stir for 3 minutes, and then add 5% of the mass of bentonite Sodium dodecylbenzenesulfonate, stirred at room temperature for 3 minutes, to obtain modified bentonite;

[0024] (2) Mixing: After mixing modified bentonite, desulfurized gypsum powder, clay and stabilizer, add clear water and stir evenly to obtain slurry;

[0025] (3) granulation: the slurry is sent into a granulator for granulation, and the obtained particle diameter is a spherical particle of 1 cm;

[0026] (4) Burning: put the spherical particles at a temperature of 600°C and burn for 30 minutes;

[0027] (5) Covering: put the calcined material above the interface between the bottom mud and water, lay a thickness of 1cm, an...

Embodiment 2

[0033] A method for controlling sediment in a eutrophic watershed, comprising the following steps:

[0034] (1) Modification: Prepare an acid solution with a concentration of 0.5 mol / L, mix it with bentonite, stir evenly in a mixer, and control the internal temperature of the mixer to 80°C, stir for 5 minutes, and then add 15% of the mass of bentonite Sodium dodecylbenzene sulfonate, stirred at room temperature for 5 minutes to obtain modified bentonite;

[0035] (2) Mixing: After mixing modified bentonite, desulfurized gypsum powder, clay and stabilizer, add clear water and stir evenly to obtain slurry;

[0036] (3) granulation: the slurry is sent into a granulator for granulation, and the obtained particle diameter is a spherical particle of 3 cm;

[0037] (4) Burning: put the spherical particles at a temperature of 800°C and burn for 60 minutes;

[0038] (5) Covering: Put the calcined material above the interface between the bottom mud and water, lay a thickness of 5cm, a...

Embodiment 3

[0044] A method for controlling sediment in a eutrophic watershed, comprising the following steps:

[0045] (1) Modification: Prepare an acid solution with a concentration of 0.3 mol / L, mix it with bentonite, stir evenly in a mixer, and control the internal temperature of the mixer to 70°C, stir for 4 minutes, and then add 10% of the mass of bentonite Sodium dodecylbenzenesulfonate, stirred at room temperature for 4min, to obtain modified bentonite;

[0046] (2) Mixing: After mixing modified bentonite, desulfurized gypsum powder, clay and stabilizer, add clear water and stir evenly to obtain slurry;

[0047] (3) granulation: the slurry is sent into a granulator for granulation to obtain spherical particles with a particle diameter of 2 cm;

[0048] (4) Burning: put the spherical particles at a temperature of 750°C and burn for 45 minutes;

[0049] (5) Covering: put the calcined material above the interface between the bottom mud and water, lay a thickness of 3cm, and then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com