Surface modification process for magnesium alloy

A surface modification, magnesium alloy technology, applied in the field of magnesium alloy surface strengthening, magnesium alloy surface modification technology, can solve the problem of increasing the galvanic corrosion tendency of the film layer, etc., to achieve the reduction of friction coefficient, increase of specific surface area, high The effect of emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

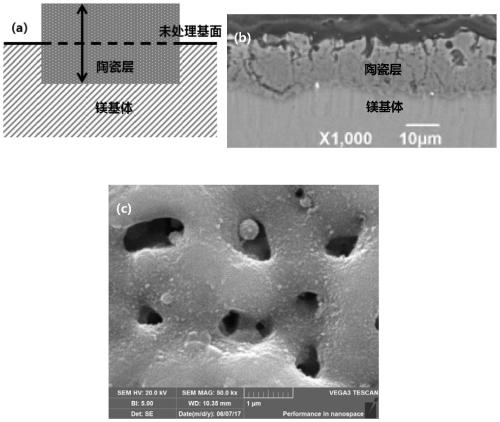

Image

Examples

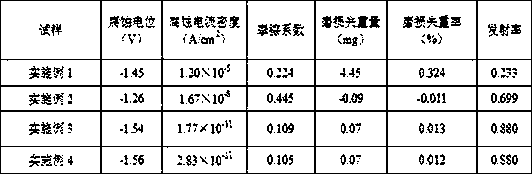

Embodiment 1

[0048] Step 1. Degreasing the surface of the VW93 magnesium alloy: the degreasing solution is: sodium hydroxide 50g / L, sodium phosphate 4g / L, sodium carbonate 6g / L, sodium lauryl sulfate 2mg / L. The degreasing temperature is 60°C and the time is 4min. After the treatment, the water droplets on the surface of the workpiece continue for 10S without interruption.

[0049] Step 2, pickling: pickling solution is: trisodium phosphate 8g / L, ammonium sulfate 3g / L, sodium nitrate 6g / L, tartaric acid 15g / L, oxalic acid 8g / L. The temperature is 45°C, and the time is 1 min. After the pickling is completed, there is no pitting on the surface of the workpiece.

[0050] Step 3, surface adjustment: surface adjustment solution is: sodium tripolyphosphate 10g / L, sodium hydroxide 20g / L, triethanolamine 5ml / L, triton 6ml / L. The temperature is 80°C, and the time is 5 minutes. After the surface adjustment is completed, the surface of the workpiece is shiny and free of residual loose oxides.

[...

Embodiment 2

[0054] Step 1, degreasing the surface of the VW93 magnesium alloy, the degreasing solution is: sodium hydroxide 50g / L, sodium phosphate 4g / L, sodium carbonate 6g / L, sodium lauryl sulfate 2mg / L. The degreasing temperature is 60°C and the time is 4min. After the treatment, the water droplets on the surface of the workpiece continue for 10S without interruption.

[0055] Step 2, pickling, the pickling solution is: trisodium phosphate 8g / L, ammonium sulfate 3g / L, sodium nitrate 6g / L, tartaric acid 15g / L, oxalic acid 8g / L. The temperature is 45°C, and the time is 1 min. After the pickling is completed, there is no pitting on the surface of the workpiece.

[0056] Step 3, surface adjustment, the surface adjustment solution is: sodium tripolyphosphate 10g / L, sodium hydroxide 20g / L, triethanolamine 5ml / L, triton 6ml / L. The temperature is 80°C, and the time is 5 minutes. After the surface adjustment is completed, the surface of the workpiece is shiny and free of residual loose oxid...

Embodiment 3

[0063] Step 1, degreasing the surface of the VW93 magnesium alloy, the degreasing solution is: sodium hydroxide 50g / L, sodium phosphate 4g / L, sodium carbonate 6g / L, sodium lauryl sulfate 2mg / L. The degreasing temperature is 60°C and the time is 4min. After the treatment, the water droplets on the surface of the workpiece continue for 10S without interruption.

[0064] Step 2, pickling, the pickling solution is: trisodium phosphate 8g / L, ammonium sulfate 3g / L, sodium nitrate 6g / L, tartaric acid 15g / L, oxalic acid 8g / L. The temperature is 45°C, and the time is 1 min. After the pickling is completed, there is no pitting on the surface of the workpiece.

[0065] Step 3, surface adjustment, the surface adjustment solution is: sodium tripolyphosphate 10g / L, sodium hydroxide 20g / L, triethanolamine 5ml / L, triton 6ml / L. The temperature is 80°C, and the time is 5 minutes. After the surface adjustment is completed, the surface of the workpiece is shiny and free of residual loose oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com