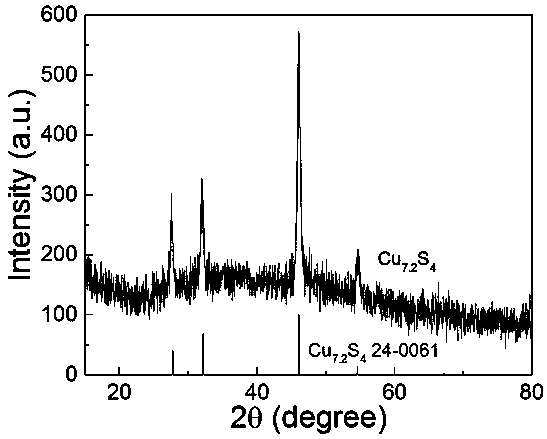

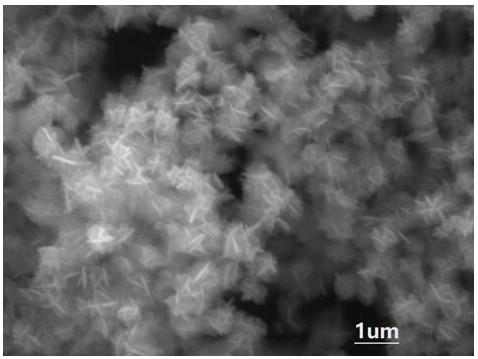

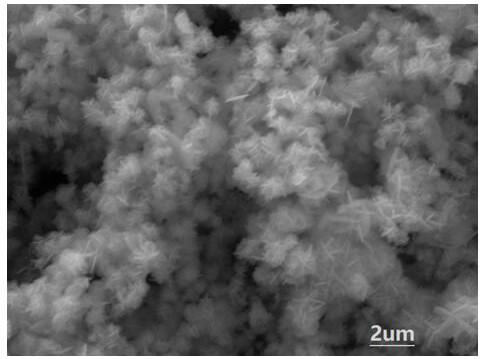

Preparation method of cuprous sulfide nano-flowers containing copper defects

A technology of cuprous sulfide and nanoflowers, applied in the field of nanomaterials, can solve the problems of difficult control of product size or shape, harsh reaction conditions, complicated preparation process, etc., and achieve the effects of low production cost, low synthesis temperature and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: A kind of preparation method of cuprous sulfide nanoflower containing copper defect, concrete steps are as follows:

[0030] Strong base (composite base of potassium hydroxide and sodium hydroxide), surfactant (trimethylhexadecyl ammonium bromide CTAB), simple copper (copper sheet), hydrazine hydrate, sodium sulfide nonahydrate and deionized Mix the water evenly and seal it in a polytetrafluoroethylene container. Place the polytetrafluoroethylene container in a heating device and heat it at a constant speed to a temperature of 200°C and react at a constant temperature for 24 hours. After cooling to room temperature, centrifuge and remove the supernatant. Wash with absolute ethanol and deionized water until the washing solution is neutral, and dry at a temperature of 30°C to obtain cuprous sulfide nanoflowers; wherein the mass ratio of potassium hydroxide to sodium hydroxide is 5.65:4.35, and strong alkali (composite base of potassium hydroxide and sodium h...

Embodiment 2

[0033] Embodiment 2: A kind of preparation method of cuprous sulfide nanoflower containing copper defect, concrete steps are as follows:

[0034] Strong base (composite base of potassium hydroxide and sodium hydroxide), surfactant (trimethylhexadecyl ammonium bromide CTAB), simple copper (copper sheet), hydrazine hydrate, sodium sulfide nonahydrate and deionized Mix the water evenly and seal it in a polytetrafluoroethylene container. Place the polytetrafluoroethylene container in a heating device and heat it at a constant speed to a temperature of 200°C and react at a constant temperature for 24 hours. After cooling to room temperature, centrifuge and remove the supernatant. Wash with absolute ethanol and deionized water until the washing solution is neutral, and dry at a temperature of 40°C to obtain cuprous sulfide nanoflowers; wherein the mass ratio of potassium hydroxide to sodium hydroxide is 5.65:4.35, and strong alkali (composite base of potassium hydroxide and sodium h...

Embodiment 3

[0036] Embodiment 3: A kind of preparation method of cuprous sulfide nanoflower containing copper defect, concrete steps are as follows:

[0037] Strong base (composite base of potassium hydroxide and sodium hydroxide), surfactant (trimethylhexadecyl ammonium bromide CTAB), simple copper (copper sheet), hydrazine hydrate, sodium sulfide nonahydrate and deionized Mix the water evenly and seal it in a polytetrafluoroethylene container. Place the polytetrafluoroethylene container in a heating device and heat it at a constant speed to a temperature of 200°C and react at a constant temperature for 24 hours. After cooling to room temperature, centrifuge and remove the supernatant. Wash with absolute ethanol and deionized water until the washing solution is neutral, and dry at a temperature of 50°C to obtain cuprous sulfide nanoflowers; wherein the mass ratio of potassium hydroxide to sodium hydroxide is 2:1, and strong alkali (composite base of potassium hydroxide and sodium hydroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com