Production system and process for 3,5-diaminobenzoic acid

A diaminobenzoic acid and production system technology, which is applied in the field of 3,5-diaminobenzoic acid production system and process, can solve the problems of poor water solubility of 3,5-diaminobenzoic acid, affecting product yield, and failure to recycle. Achieve the effects of avoiding the oxidation of amino groups, improving yield and purity, and reducing artificial input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

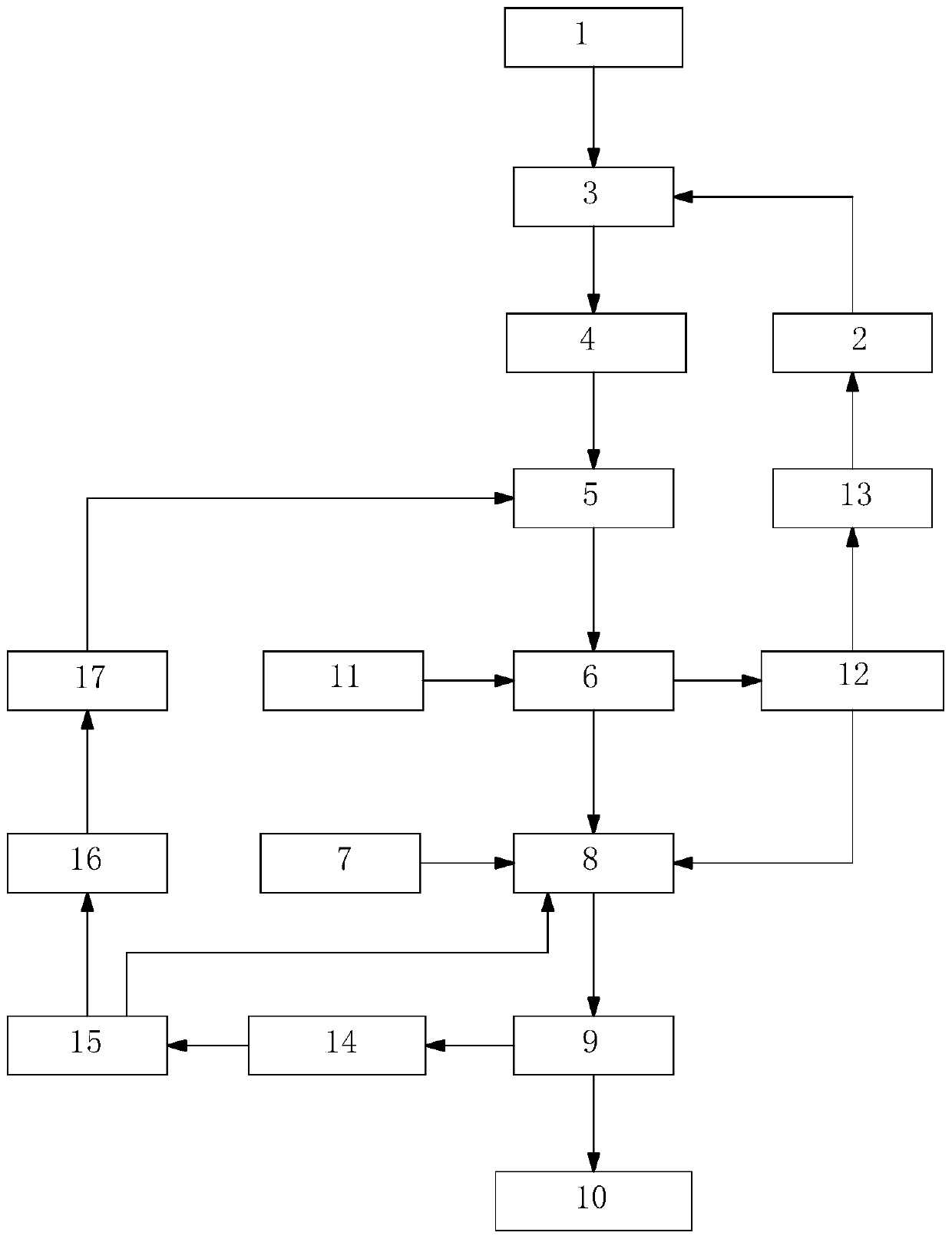

[0045] A 3,5-diaminobenzoic acid production system, including nitro material tank 1, water storage tank 2, slurry mixing pot 3, slurry metering tank 4, reduction pot 5, filter press 6, acid metering tank 7, acid Analysis pot 8, centrifuge 9, flash dryer 10, hot water tank 11, concentration pot 12, first condenser 13, cryogenic desalination tank 14, distillation still 15, second condenser 16, condensed water tank 17;

[0046] The nitro material tank 1 and the water storage tank 2 are all communicated with the feed port of the pulp mixing pot 3, the discharge port of the slurry mixing pot 3 is connected with the feed port of the slurry metering tank 4, and the discharge port of the slurry metering tank 4 is connected with the feed port of the slurry metering tank 4. The feed port of reduction pot 5 is connected, the discharge port of reduction pot 5 is connected with the feed port of filter press 6, and the discharge port of filter press 6 and the acid metering tank are all conne...

Embodiment 2

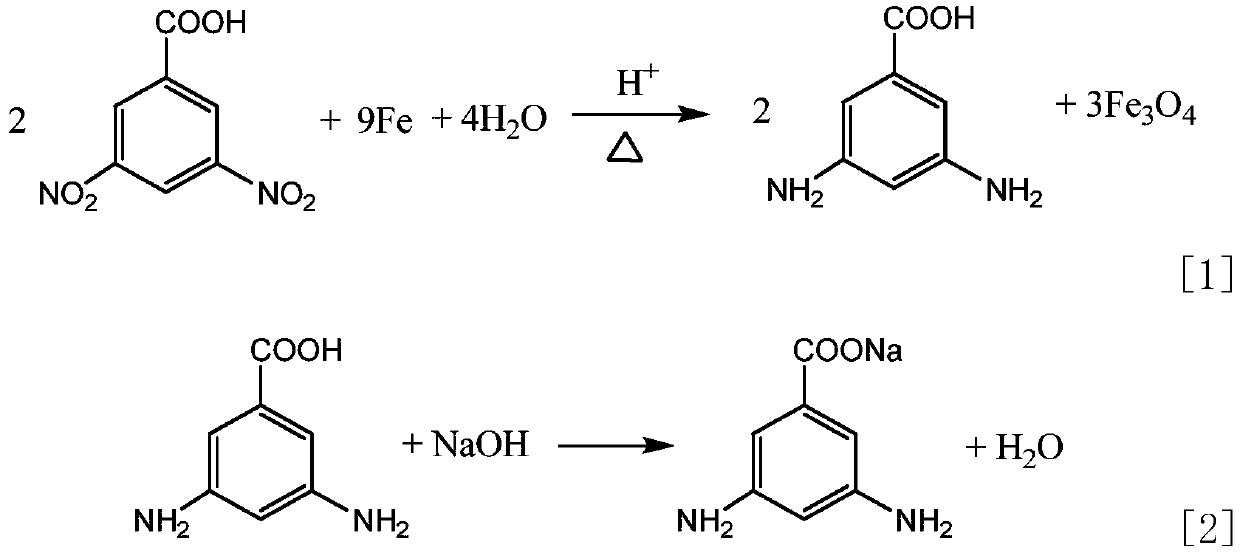

[0050] A process for producing 3,5-diaminobenzoic acid using a 3,5-diaminobenzoic acid production system described in Example 1, which includes the following steps: S1. Slurry preparation; S2. Reduction; S3. Acid analysis; of:

[0051] S1. Blending: Open the blending pot 3, stir at 40r / min, add 970Kg of bottom water to the blending pot 3, then add 630Kg of 3,5-dinitrobenzoic acid dry powder to the blending pot 3, and stir to form Uniform 3,5-dinitrobenzoic acid slurry; beat the prepared 3,5-dinitrobenzoic acid slurry into the slurry metering tank 4 for subsequent use;

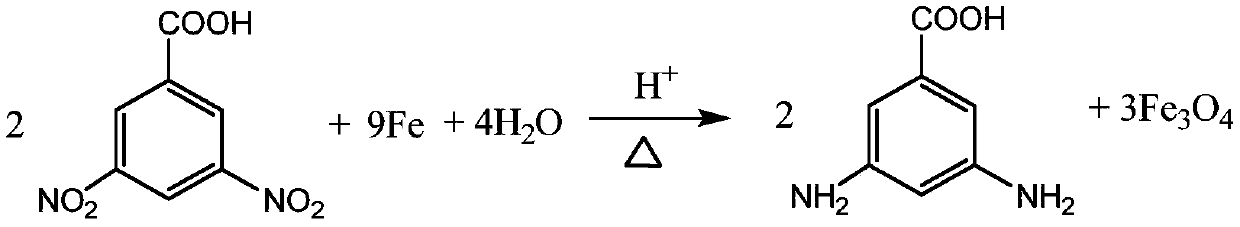

[0052] S2. Reduction: Add 4000Kg of bottom water in the reduction kettle, stir at 80r / min, add 400Kg of 60-80 mesh iron powder and 520Kg of 20-40 mesh iron powder, and then add 40Kg of HCl, HCl is added in the form of hydrochloric acid, Raise the temperature to 95°C and keep it warm for 1h, add 1760Kg of 3,5-dinitrobenzoic acid slurry obtained in S1. During the process of dinitrobenzoic acid slurry, add 2.2Kg...

Embodiment 3

[0061] A process for producing 3,5-diaminobenzoic acid using a 3,5-diaminobenzoic acid production system described in Example 1, comprising the following steps: S1. Slurry preparation; S2. Reduction; S3. Acid analysis; specific :

[0062] S1. Blending: Open the blending pot 3, stir at 40r / min, add 1050Kg of bottom water to the blending pot 3, then add 630Kg of 3,5-dinitrobenzoic acid dry powder into the blending pot 3, and stir to form Uniform 3,5-dinitrobenzoic acid slurry; beat the prepared 3,5-dinitrobenzoic acid slurry into the slurry metering tank 4 for subsequent use;

[0063] S2. Reduction: Add 4000Kg of bottom water in the reduction kettle, stir at 80r / min, add 520Kg of 60-80 mesh iron powder and 560Kg of 20-40 mesh iron powder, and then add 44Kg of HCl, HCl is added in the form of hydrochloric acid, Raise the temperature to 98°C and keep it warm for 1.25h, add 1840Kg of 3,5-dinitrobenzoic acid slurry obtained in S1. - Add 2.3Kg of sodium bisulfite every 2 hours duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com