A kind of water-based flocking glue and preparation method thereof

A flocking glue, water-based technology, applied in the direction of adhesives, adhesive types, graft polymer adhesives, etc., can solve the problems of stability, water resistance, poor hand feel and breathability and moisture permeability, abrasion resistance, water resistance and softness Insufficient water resistance, poor wear resistance and other problems, to achieve the effect of excellent hand feel and air permeability and moisture permeability, the preparation method is simple and easy to operate, and the effect of improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

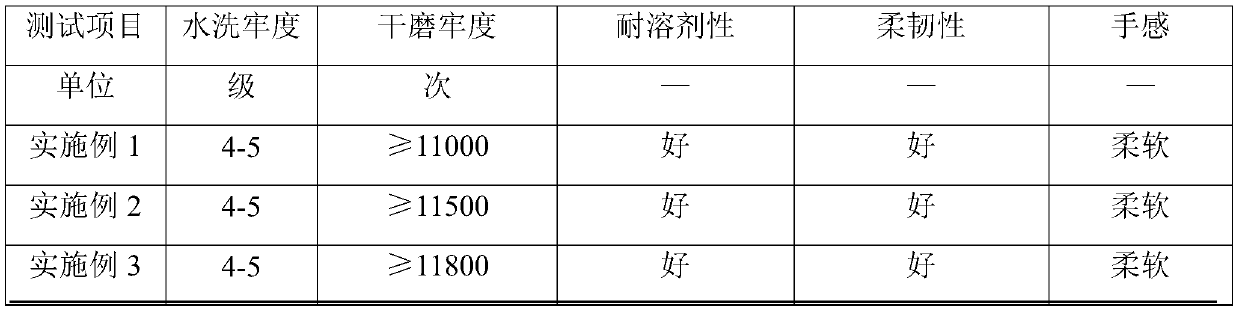

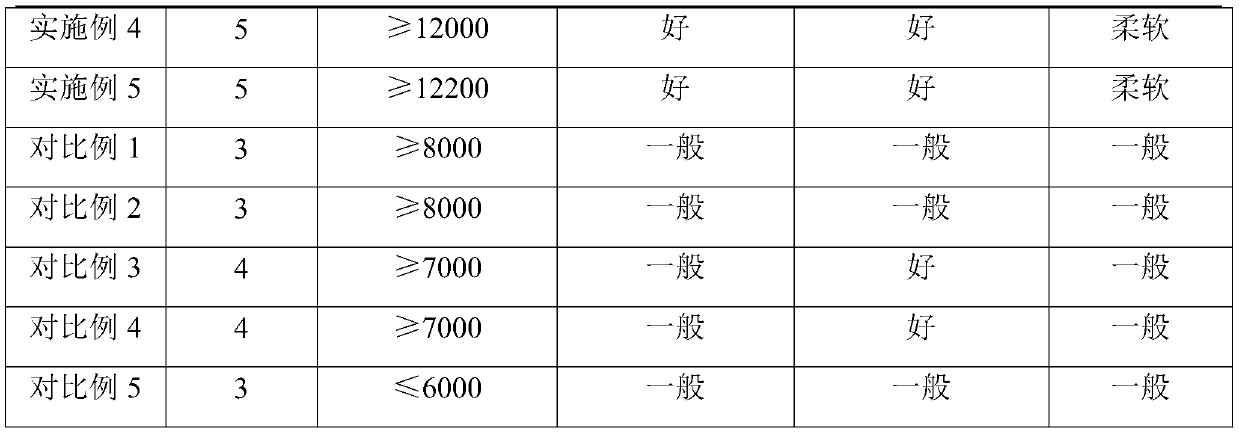

Examples

preparation example Construction

[0021] The emulsifier is at least one of sodium lauryl sulfate, secondary alcohol fatty alcohol polyoxyethylene ether, castor oil polyoxyethylene ether and alkylphenol ether sulfosuccinic acid sodium salt. The initiator is at least one of potassium persulfate, sodium persulfate, ammonium persulfate and azodiisopropylimidazoline hydrochloride. The preparation method of described 3-chloro-2-hydroxypropyl acrylate ionized modified hyperbranched polyethyleneimine comprises the following steps: dissolving 3-chloro-2-hydroxypropyl acrylate and hyperbranched polyethyleneimine in In N,N-dimethylacetamide, stir the reaction at 60-80°C for 4-6 hours, then remove N,N-dimethylacetamide by rotary evaporation, wash the product 3-5 times with ether, and then place Dry in a vacuum oven at 80-90°C until constant weight. The mass ratio of the 3-chloro-2-hydroxypropyl acrylate, hyperbranched polyethyleneimine and N,N-dimethylacetamide is 1:1:(8-12). The preparation method of the fluorine-conta...

Embodiment 1

[0026] Embodiment 1 provides a water-based flocking glue, which is made of the following raw materials in parts by weight: 20 parts of water-soluble terminal acrylate-based hyperbranched polyester, 3-chloro-2-hydroxypropyl acrylate ionized modified hyperbranched 5 parts of polyethyleneimine, 30 parts of hydroxyl-terminated waterborne polyurethane, 1 part of blocked isocyanate crosslinking agent, D-mannitol 1,6-di(2-isocyano-3-methyl-2-butenoate ) 1 part, 0.5 part of fluorine-containing trihydroxysilane compound, 2 parts of sodium lauryl sulfate, 0.1 part of potassium persulfate, and 50 parts of water.

[0027] The preparation method of the 3-chloro-2-hydroxypropyl acrylate ionized modified hyperbranched polyethyleneimine comprises the following steps: 1 kg of 3-chloro-2-hydroxypropyl acrylate, 1 kg of hyperbranched polyethyleneimine Dissolve in 8 kg of N,N-dimethylacetamide, stir and react at 60°C for 4 hours, then remove N,N-dimethylacetamide by rotary evaporation, wash the p...

Embodiment 2

[0035] Embodiment 2 provides a kind of water-based flocking glue and preparation method thereof, and it is basically consistent with embodiment 1, and difference is only, described water-based flocking glue is made of each raw material of following weight portion: water-soluble terminal acrylic acid 23 parts of ester-based hyperbranched polyester, 7 parts of ionized modified hyperbranched polyethyleneimine with 3-chloro-2-hydroxypropyl acrylate, 33 parts of hydroxyl-terminated waterborne polyurethane, 2 parts of blocked isocyanate crosslinking agent, D- 1.5 parts of mannitol 1,6-bis(2-isocyano-3-methyl-2-butenoate), 0.7 parts of fluorine-containing trihydroxysilane compounds, 3 parts of secondary alcohol fatty alcohol polyoxyethylene ether, 0.2 parts of sodium persulfate, 53 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com