Preparation method and application of modified thin-wall hierarchical porous carbon for lithium-sulfur battery

A lithium-sulfur battery, multi-level hole technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of not eliminating the source of lithium dendrites, delaying the time of lithium dendrite occurrence, etc., to improve the passivation effect, The effect of suppressing shuttle and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment one: cobalt nitrate thiourea ligand solution

[0043] Thiourea (1.52g, 0.02mol) was dissolved in 4 times its mass of deionized water (6.08g) to obtain a thiourea solution, and hexahydrate cobalt nitrate (2.91g, 0.01mol) was dissolved in its 10 times its mass of deionized water (29.1g) to obtain a cobalt nitrate solution, the cobalt nitrate solution was slowly added to the thiourea solution, stirred for 2h to obtain a cobalt nitrate thiourea ligand solution, and the molar ratio of cobalt nitrate to thiourea was 1:2.

Embodiment 2

[0044] Example 2: Prepolymerization of Nickel Coordination Glucose Thiourea Resin

[0045] Thiourea (2.28g, 0.03mol) was dissolved in deionized water (9.12g) to obtain thiourea solution, and nickel chloride hexahydrate (2.38g, 0.01mol) was dissolved in deionized water (23.8g) to obtain nickel chloride solution, nickel chloride solution was slowly added to thiourea solution, and stirred for 2 hours to obtain nickel chloride thiourea ligand solution, the molar ratio of nickel chloride to thiourea was 1:3.

[0046] Sodium chloride (1.75 g, 0.03 mol) was dissolved in 7 mL of deionized water to obtain a sodium chloride solution. 5.94 g (0.03 mol) of glucose monohydrate was dissolved in 5.94 mL of deionized water to obtain a glucose solution. Add the above-mentioned nickel chloride thiourea ligand solution into the glucose solution, the molar ratio of glucose to thiourea is 1:1, place in a water bath at 85°C, add 10wt% hydrochloric acid dropwise and fully stir to make the pH value ...

Embodiment 3

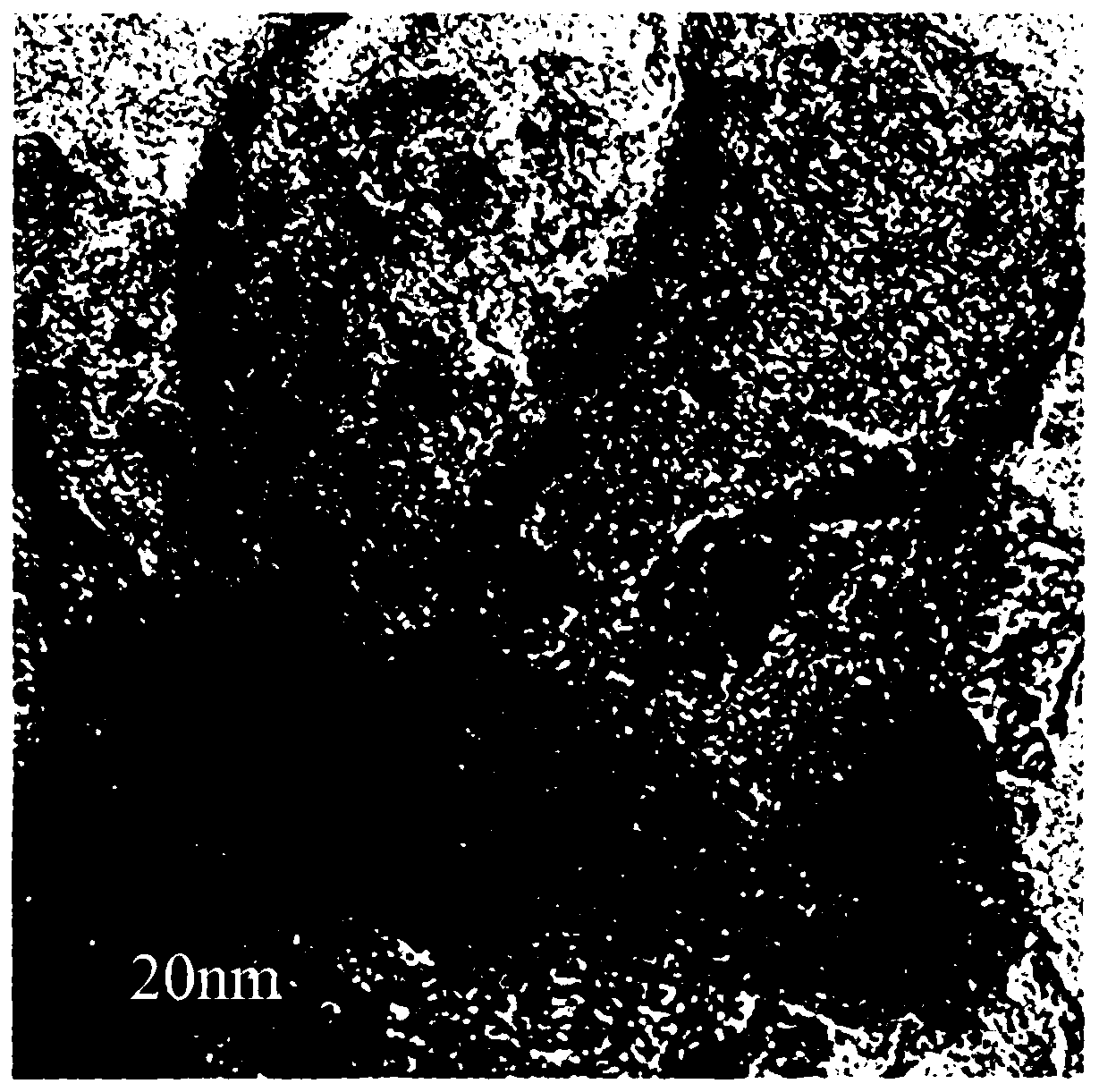

[0047] Example 3: Preparation of nano-tin sulfide modified thin-walled hierarchical porous carbon

[0048] Thiourea (3.04g, 0.04mol) was dissolved in deionized water (12.16g) to obtain thiourea solution, and stannous chloride dihydrate (2.26g, 0.01mol) was dissolved in deionized water (22.6g) to obtain chlorinated For stannous solution, slowly add stannous chloride solution into thiourea solution, stir for 2 hours to obtain stannous chloride thiourea ligand solution, the molar ratio of stannous chloride to thiourea is 1:4.

[0049] Sodium chloride (11.69 g, 0.2 mol) was dissolved in 46.76 mL of deionized water to obtain a sodium chloride solution. 7.93 g (0.04 mol) of glucose monohydrate was dissolved in 7.93 mL of deionized water to obtain a glucose solution. Add the above stannous chloride thiourea ligand solution into the glucose solution, the molar ratio of glucose and thiourea usage is 1:1, put it in a water bath at 85°C, add 10wt% hydrochloric acid dropwise and fully st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com