Flue gas deep treatment method for simultaneous desulfurization and denitrification by absorption method

A technology for desulfurization, denitrification, and advanced treatment, which is applied in separation methods, chemical instruments and methods, and air quality improvement. It can solve the problems of low NO removal rate, low removal rate, and difficult industrial application, so as to improve denitrification efficiency and prolong stability. Effects of time, accelerated dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

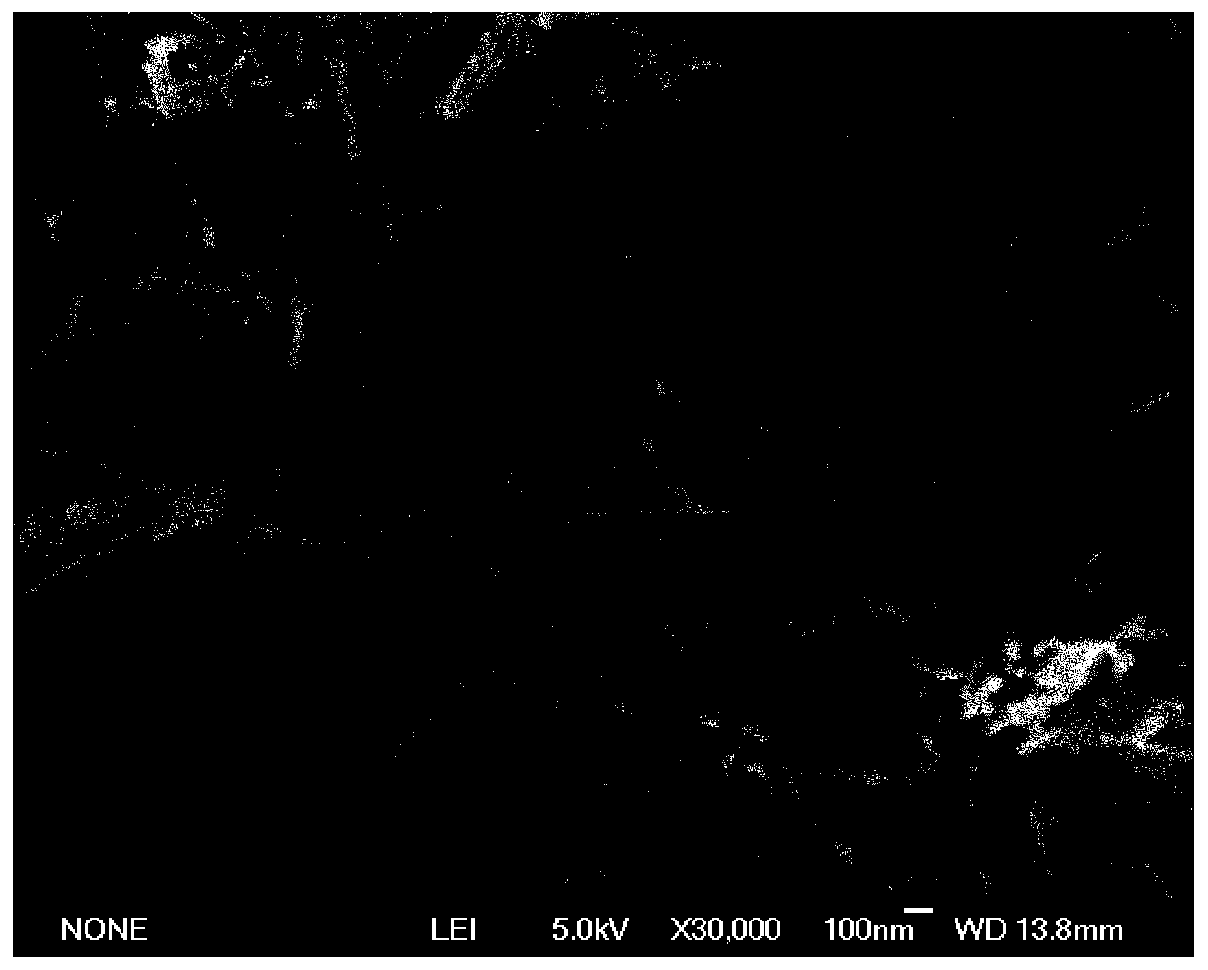

[0037] Select manganese oxide ore from a place in Anhui, the chemical composition of the ore is: SiO 2 , 34.63%; MnO, 20.91%; Fe 2 o 3 , 5.58%; Al 2 o 3 , 4.23%; CaO, 2.21%; ZnO, 1.64%; K 2 O, 1.04%; MgO, 0.65%; P 2 o 5 , 0.56%; loss on ignition, 27.65%; others, 0.9%. The content of manganese oxide is 26.4%, and the microscopic characteristics of manganese oxide can be seen in figure 1 .

[0038] Grind the manganese oxide ore in a ball mill for 60 minutes, and sieve to obtain a 325-mesh powder. Then mix it according to the mass ratio of manganese oxide powder and water at 1:10 to make a suspension. Add polyethylene glycol accounting for 3% of the mass of the suspension to the suspension, and then adjust the pH of the suspension to 4 with sulfuric acid to obtain an absorption liquid for simultaneous desulfurization and denitrification.

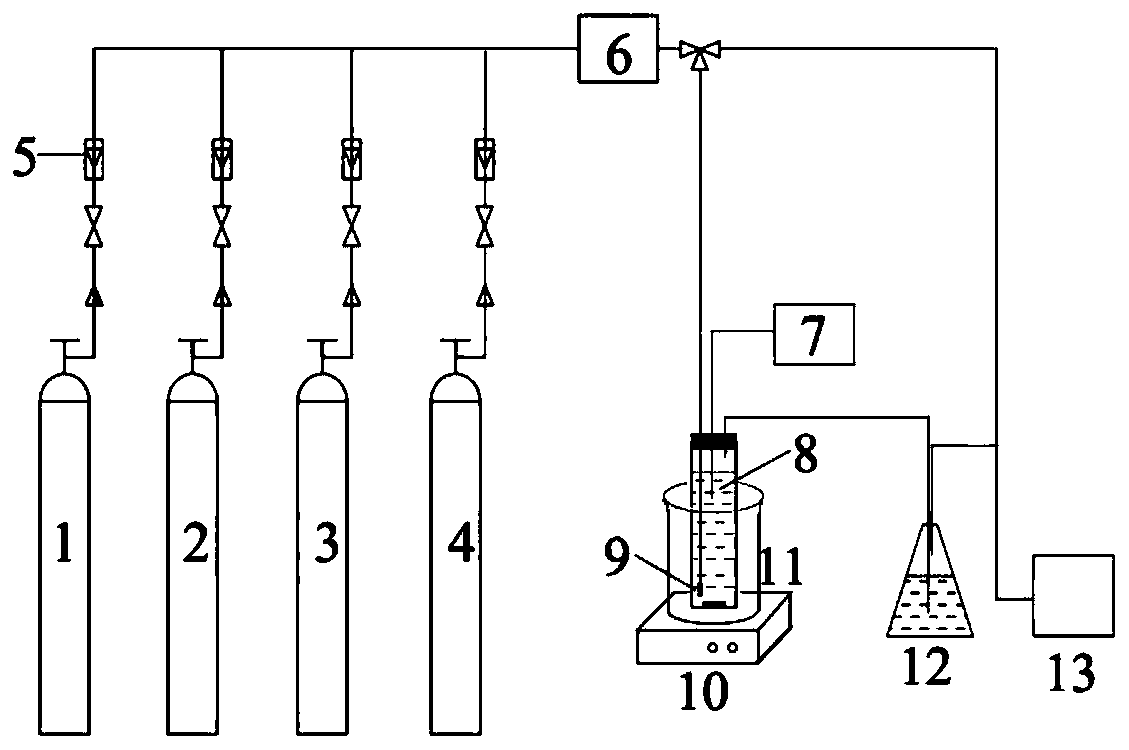

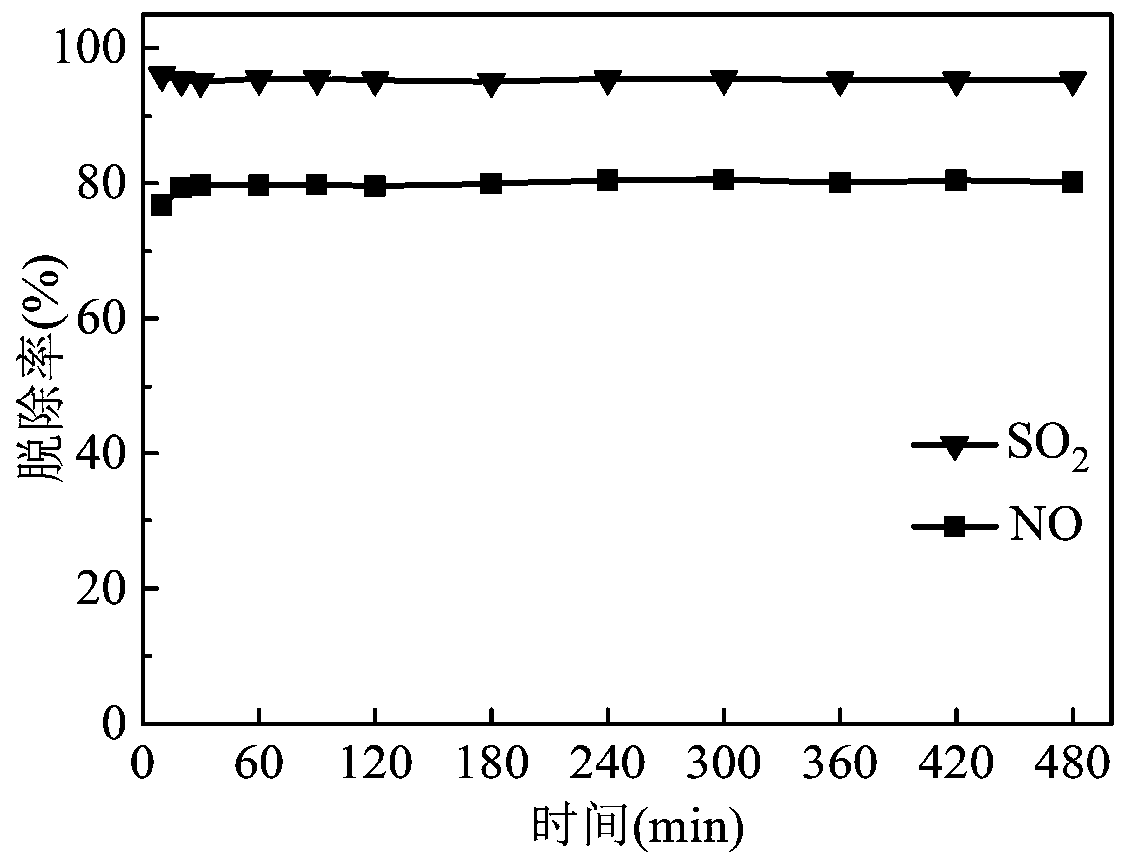

[0039] Put the absorbent into the figure 2 In the simulated experimental device shown, the NO / Ar, SO 2 0.1% SO by volume 2 / Ar,O...

Embodiment 2

[0041] Select manganese oxide ore from a place in Anhui, the chemical composition of the ore is: SiO 2 , 34.63%; MnO, 20.91%; Fe 2 o 3 , 5.58%; Al 2 o 3 , 4.23%; CaO, 2.21%; ZnO, 1.64%; K 2 O, 1.04%; MgO, 0.65%; P 2 o 5 , 0.56%; loss on ignition, 27.65%; others, 0.9%. The content of manganese oxide is 26.4%, and the microscopic characteristics of manganese oxide can be seen in figure 1 .

[0042] Grind the manganese oxide ore in a ball mill for 30 minutes, and sieve to obtain a 325-mesh powder. Then mix it according to the mass ratio of manganese oxide ore powder and water at 1:20 to make a suspension. Add polyethylene glycol accounting for 0%, 0.2%, 0.6%, 1.0%, 1.4%, 1.8%, 2.2%, 2.6%, 3.0%, 3.4%, 3.8% of the suspension mass to the suspension, and then use sulfuric acid Adjust the pH of the suspension to 4, namely to obtain absorption solutions with different polyethylene glycol concentrations for simultaneous desulfurization and denitrification.

[0043] The absorp...

Embodiment 3

[0045] Select manganese oxide ore from a place in Anhui, the chemical composition of the ore is: SiO 2 , 34.63%; MnO, 20.91%; Fe 2 o 3 , 5.58%; Al 2 o 3 , 4.23%; CaO, 2.21%; ZnO, 1.64%; K 2 O, 1.04%; MgO, 0.65%; P 2 o 5 , 0.56%; loss on ignition, 27.65%; others, 0.9%. The content of manganese oxide is 26.4%, and the microscopic characteristics of manganese oxide can be seen in figure 1 .

[0046] Grind the manganese oxide ore in a ball mill for 30 minutes, and sieve to obtain a 325-mesh powder. Then mix according to the mass ratio of pyrolusite powder and water at 1:30 to make a suspension. Add 3.0% polyethylene glycol to the suspension, and then adjust the pH of the suspension to 3 with sulfuric acid to obtain an absorption liquid for simultaneous desulfurization and denitrification.

[0047] Put the absorbent into the figure 2 In the simulated experimental device shown, the NO / Ar, SO 2 0.1% SO by volume 2 / Ar,O 2 15% by volume O 2 / Ar gas distribution for abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com