Preparing method and application of nitrogen-doped sludge carbon-loaded nanometer ferroferric oxide

A technology of ferroferric oxide and sludge carbon, which is applied in the field of comprehensive waste utilization and water treatment, can solve the problems of high cost of activated carbon, unfavorable long-term use, environmental pollution, etc., and achieve high value-added utilization, high energy recovery, The effect of good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

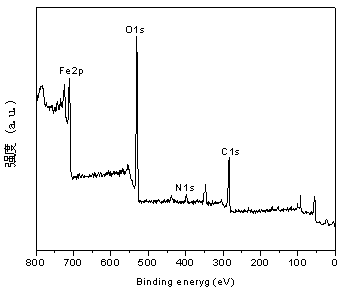

Embodiment 1

[0035] The raw sewage sludge is dehydrated to a moisture content of 80-85%, pickled with 1mol / L HCl, stirred slowly by a stirrer for 3 hours, dried in an oven at 85°C for 12 hours, and crushed to a particle size of 2 As an activator, the impregnation volume ratio of the dried hydrothermal biochar was 3:1. After 4 hours of immersion, it was allowed to stand still for 10 hours. The supernatant was recovered and dried at 95°C for 12 hours. Then carry out high-temperature closed carbonization, the temperature of the high-temperature carbonization process is 700°C, the pyrolysis time is 3 hours, and high-purity nitrogen gas is introduced at a flow rate of 500mL / min to perform double nitrogen doping treatment. The final product was acid-washed with HCl, washed with distilled water, and the pH of the final eluent did not change, and dried at 105° C. for 12 hours to obtain nitrogen-doped sludge charcoal. Nitrogen-doped sludge with Fe 2+ The salt is dispersed in the aqueous solution, a...

Embodiment 2

[0045] The raw sewage sludge is dehydrated to a moisture content of 80-85%, pickled with 1mol / L HCl, stirred slowly by a stirrer for 3 hours, dried in an oven at 85°C for 12 hours, and crushed to a particle size of 2+ The salt is dispersed in the aqueous solution, and after passing nitrogen gas for 60 minutes, the aqueous solution is heated to 100°C and maintained at the temperature, and saturated sodium hydroxide solution is added dropwise until the pH of the aqueous solution is about 11 to carry out co-precipitation reaction. After magnetic separation, the co-precipitated product was pickled with HCl and washed with distilled water. The pH of the final eluate did not change. It was dried at 105°C for 12 hours and crushed to a particle size of <0.1 mm to obtain nitrogen-doped sludge carbon-loaded nanoparticles. Ferric oxide is sample 2.

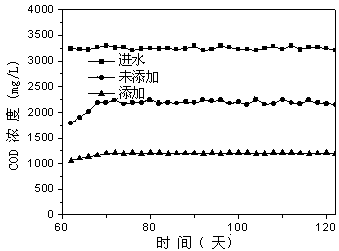

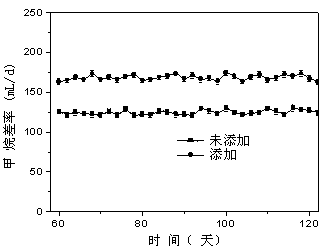

[0046] Sample 2 is used to strengthen the anaerobic treatment of high-concentration printing and dyeing wastewater. The anaerobic reactor ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com