Preparation and application of a nitrogen-doped ternary sulfide electrocatalyst material

A sulfide electrocatalyst technology, applied in the direction of physical/chemical process catalyst, chemical/physical process, electrode, etc., can solve problems such as the reduction of catalytic water splitting efficiency, and achieve high practical application value, simple process, and easy process control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

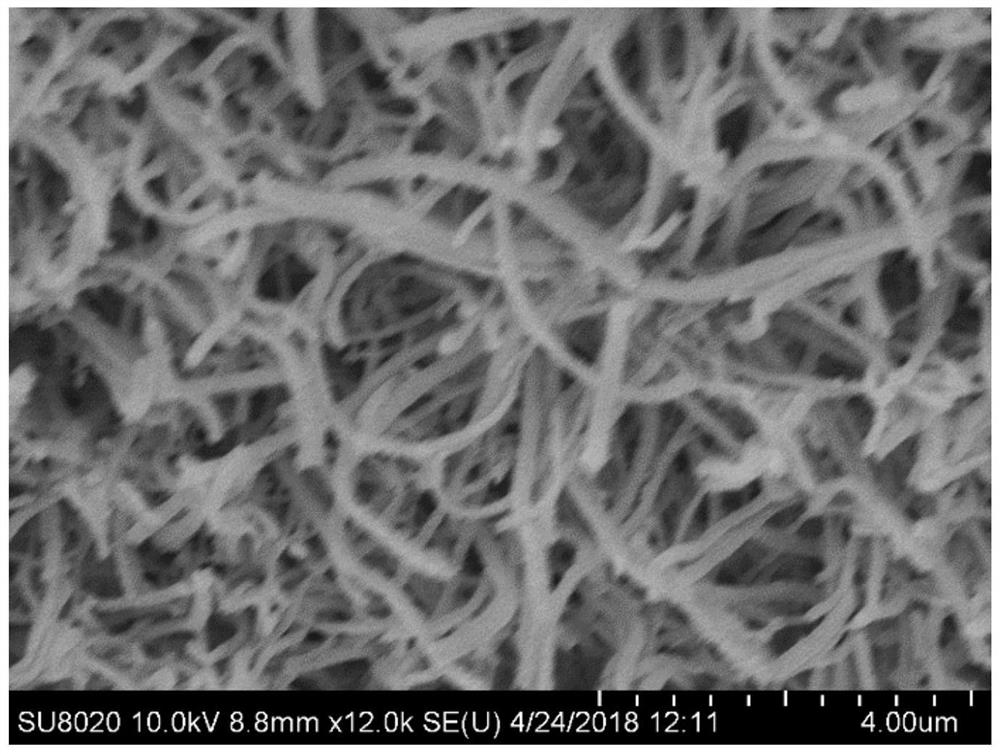

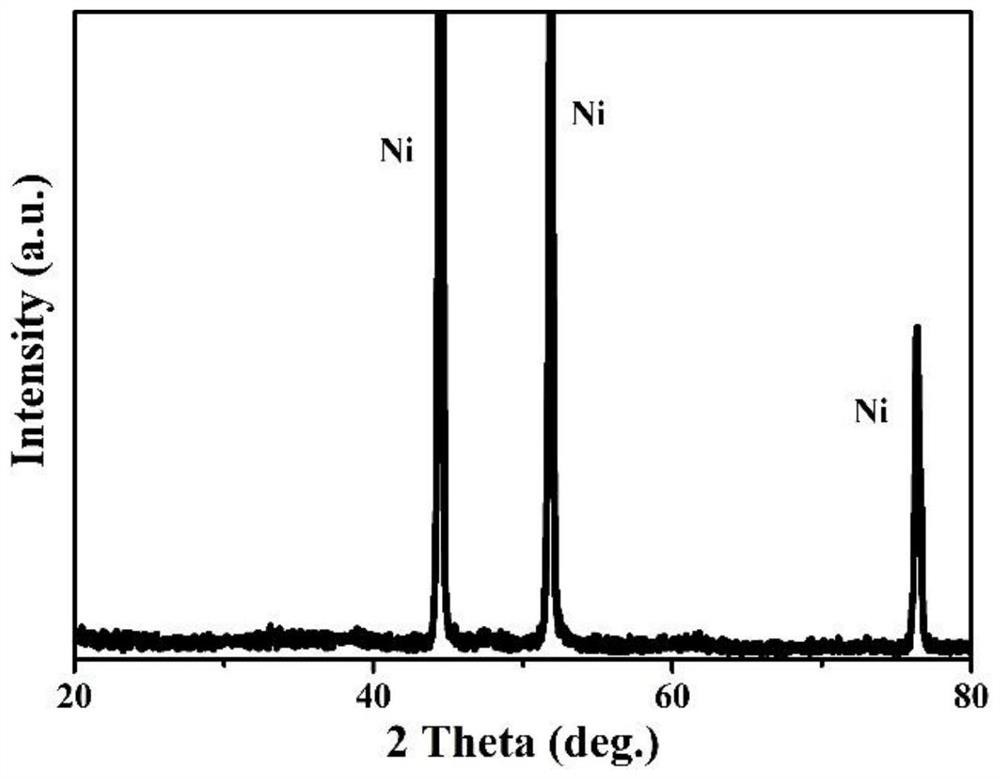

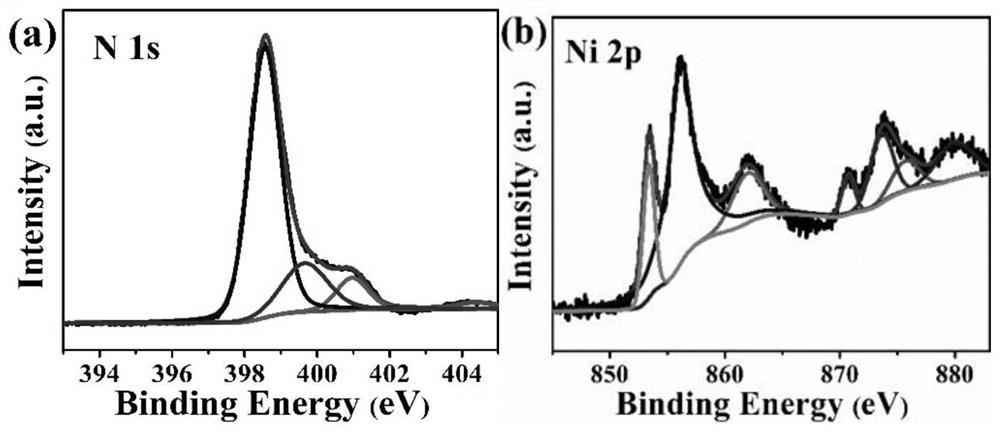

[0024] Put the cleaned foamed nickel vertically into the lining of the hydrothermal kettle, then add a mixed solution of sodium molybdate and nickel chloride with a concentration of 6mmol / L, then put it into a stainless steel autoclave jacket and seal it, place it in React in an oven at 160° C. for 10 hours. After the reaction is completed, cool down to room temperature naturally, and wash the nickel sheet with distilled water and ethanol several times. Then put into the mixed solution of sodium sulfide and thioacetamide, the concentrations are 10mmol / L and 0.5mmol / L respectively, and react in hydrothermal reaction at 140°C for 24h. After the reaction, the nickel sheet is taken out, washed 3 to 5 times with deionized water, and dried at 80°C. That is, nitrogen-doped NiMoS grown on a nickel foam substrate 4 Electrocatalyst, from figure 1 It can be seen that a linear structured catalyst is obtained.

Embodiment 2

[0026] Put the cleaned foamed nickel vertically into the lining of the hydrothermal kettle, then add a mixed solution of sodium molybdate and cobalt nitrate with a concentration of 4mmol / L, then put it into a stainless steel autoclave jacket and seal it, and place it at 150 The reaction was carried out in an oven at ℃ for 16 hours. After the reaction was completed, it was naturally cooled to room temperature, and the nickel sheet was cleaned several times with distilled water and ethanol respectively. Then put into the mixed solution of sodium sulfide and thiourea, the concentrations are 6mmol / L and 1mmol / L respectively, and react in hydrothermal reaction at 160°C for 12h. After the reaction, the nickel sheet is taken out, washed 3 to 5 times with deionized water, and dried at 80°C. That is, nitrogen-doped CoMoS grown on a nickel foam substrate 4 electrocatalyst.

Embodiment 3

[0028] Put the mixed solution of sodium molybdate and cobalt chloride with a concentration of 8mmol / L into the jacket of a stainless steel autoclave and seal it, place it in an oven at 200°C for 24 hours, and cool it naturally to room temperature after the reaction is completed. Wash several times with distilled water and ethanol. Then put into the mixed solution of sodium sulfide and thiourea, the concentrations are 12mmol / L and 1.5mmol / L respectively, and react in hydrothermal reaction at 180°C for 12h. After the reaction, the product was collected, washed 3 to 5 times with deionized water and absolute ethanol, and dried at 80°C. That is, nitrogen-doped CoMoS 4 electrocatalyst particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com