A kind of degreasing agent used for oil field poly-containing sewage treatment and preparation method thereof

A technology of sewage treatment and degreasing agent, which is applied in the direction of water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem that the degreasing rate of poly-containing sewage cannot reach the expected effect and is not applicable Solve the problems of degreasing treatment of poly-containing sewage, complex and changeable operation methods, etc., to achieve the effects of easy acquisition, transportation and storage, high degreasing efficiency and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

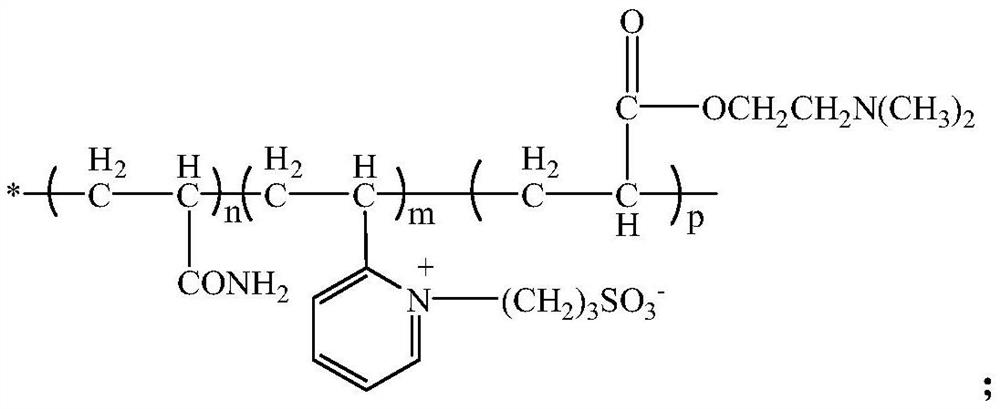

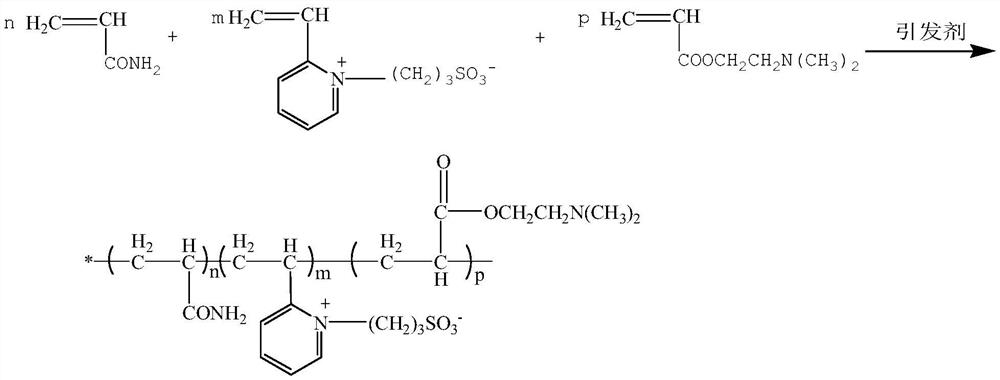

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Oil Waste Waffi Water Treatment for Oilfield 1 Preparation method

[0027] (1) 1 mol acrylamide is added to three flasks equipped with a reflow condensate, a stirrer, and a thermometer, then 1421.6 g of distilled water and pH regulator NaOH solution, pH adjusting to 7, warmed to 30 ° C, at a stirring rate of 200 rpm The mixture was stirred for 10 min, then 0.071 g of formaldehyde syndrhythulfite, 0.107 g of EDTA and 0.355 g of azoiisopropylimidazoline were added, and the stirring rate was adjusted to 400 rpm, the stirring time was 10 min, and after completion, it was completely dissolved to obtain a mixture Solution.

[0028] (2) 0.1 mol 1- (3-sulfonate) -2-vinylpyridinonium salt salt and 0.01 mol acrylate were added to 0.01 mol acrylate, respectively, and 0.569 g was added after 40 minutes of nitrogen gas. Ammonium persulfate, continued to pass into nitrogen, then warmed to 75 ° C, and the constant temperature was 30 min, and the reaction was completely cooled t...

Embodiment 2

[0033] Example 2: Oil Waste Waffi Willed Water Treatment for Oilfield 2 Preparation method

[0034] (1) 1 mol acrylamide is added to three flasks equipped with a reflow condensate, a stirrer, and the thermometer is added, then 2012.5 g of distilled water and pH adjusting agent NaOH solution, pH adjustment to 8, warmed to 38 ° C, at a stirring rate of 220 rpm The mixture was stirred for 17 min, then 0.103 g of formaldehyde syndrhythulfite, 0.213 g of EDTA and 0.627 g of azoiisopropylimidazoline were added, and the stirring rate was adjusted to 480 rpm, the stirring time was 16 min, and after the dissolution, it was mixed Solution.

[0035] (2) 0.36 mol 1- (3-sulfonate) -2-vinylpyridinium inlenium salt salt and 0.4 mol acrylate were added in the mixed solution, respectively, and 1.125 g was added after 30 min of nitrogen. Ammonium sulfate, continued to pass into nitrogen, then warmed to 82 ° C, the constant temperature reaction was 50 min, and the reaction was completely cooled to r...

Embodiment 3

[0040] Example 3: Oil Willer W for Field Confucius Treatment 3 Preparation method

[0041] (1) 1 mol acrylamide is added to three flasks equipped with a reflow condensate, a stirrer, and then 2487.8 g of distilled water and a pH condition NaOH solution, pH adjusting to 9, warmed to 50 ° C, at a stirring rate of 300 rpm The mixture was stirred for 20 min, then 0.142 g of formaldehyde syndrhythulfite, 0.165 g of EDTA, and 0.853 g of azoiisopropylimidazoline, the stirring rate was adjusted to 600 rpm, the stirring time was 20 min, and after completion of complete dissolution, it was mixed Solution.

[0042] (2) 1.5 mol 1- (3-sulfonate) -2-vinylpyridinium inlenium in the above mixing solution is added to 0.9 mol acrylate dimethylaminethyl escetate, and 1.777 g is added after 50 min. Ammonium sulfate and continued to pass nitrogen, then warmed to 90 ° C, 40 min at a constant temperature, and then cooled to room temperature after completion to obtain a polymer solution.

[0043] (3) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com