Distribution type biomass gasification poly-generation system and distribution type biomass gasification poly-generation method

A biomass and polygeneration technology, applied in the field of energy and environment, can solve the problems of waste heat resource waste, reduce thermal efficiency, etc., and achieve the effect of saving energy, reducing transportation costs, and achieving significant environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

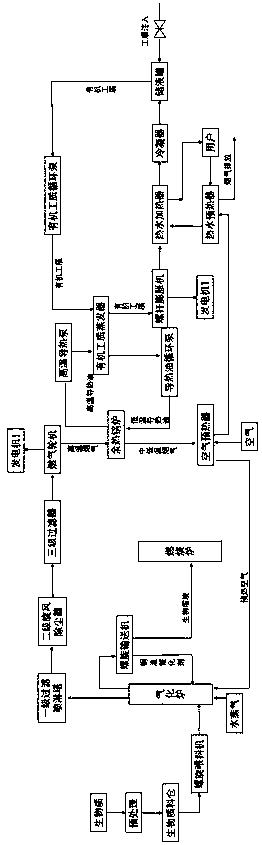

[0033] Embodiment 1: as figure 1 As shown, a distributed biomass gasification polygeneration system includes a biomass silo, a screw feeder, a fluidized bed gasifier, a combustion furnace, a screw conveyor, a gas turbine, a primary filter spray tower, a secondary Class cyclone dust collector, three-stage filter, waste heat boiler, air preheater, organic working medium evaporator, screw expander, hot water heater, hot water preheater, heat storage tank,

[0034] The outlet of the biomass silo is connected to the material inlet Ⅰ of the fluidized bed gasifier through the biomass conveying pipe Ⅰ, and the bottom discharge port of the fluidized bed gasifier is connected to the inlet of the screw conveyor through the biomass conveying pipe Ⅱ. The outlet of the screw conveyor returns to the bottom of the fluidized bed gasifier through the biomass delivery pipeline III, the outlet of the screw conveyor communicates with the bottom feed port of the combustion furnace through the bioma...

Embodiment 2

[0035] Embodiment 2: as figure 1 As shown, a distributed biomass gasification polygeneration system includes a biomass silo, a screw feeder, a fluidized bed gasifier, a combustion furnace, a screw conveyor, a gas turbine, a primary filter spray tower, a secondary Class cyclone dust collector, three-stage filter, waste heat boiler, air preheater, organic working medium evaporator, screw expander, hot water heater, hot water preheater, heat storage tank,

[0036] The outlet of the biomass silo is connected to the material inlet Ⅰ of the fluidized bed gasifier through the biomass conveying pipe Ⅰ, and the bottom discharge port of the fluidized bed gasifier is connected to the inlet of the screw conveyor through the biomass conveying pipe Ⅱ. The outlet of the screw conveyor returns to the bottom of the fluidized bed gasifier through the biomass delivery pipeline III, the outlet of the screw conveyor communicates with the bottom feed port of the combustion furnace through the bioma...

Embodiment 3

[0039] Embodiment 3: Distributed biomass gasification polygeneration method, adopting distributed biomass gasification polygeneration system (see figure 1 ),Specific steps are as follows:

[0040] (1) Biomass is added to the biomass silo after pretreatment, and the biomass in the biomass silo is fed into the fluidized bed gasifier through the screw feeder, and the air preheated by the air preheater is preheated The air delivery pipe leads into the fluidized bed gasifier to react with biomass to generate biomass charcoal and crude gas;

[0041] (2) Biomass charcoal in the fluidized bed gasifier enters the screw conveyor through the biomass conveying pipeline II, and the biochar used as the copper slag catalyst in the screw conveyor returns to the bottom of the fluidized bed gasifier, and the biochar in the screw conveyor The remaining biomass charcoal is transported to the combustion furnace for combustion through the biomass transportation pipeline IV;

[0042] (3) The crude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com