Shrimp oil powder condiment and preparation method thereof.

The technology of seasoning and shrimp oil is applied in the direction of bacteria, sugar-containing food ingredients, lactobacillus used in food preparation, etc., which can solve the problems of high salt content, consumer acceptance, and difficulty in becoming a condiment for ordinary household dishes, etc. Achieving the effect of rich nutrition, simple process and improvement of bad smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A preparation method of shrimp oil powder seasoning, comprising the steps of:

[0052](1) Add white sugar, starch, yeast extract, monosodium glutamate, disodium nucleotide, disodium succinate, maltodextrin, β-cyclodextrin, peach gum, Ginger powder, garlic powder, white pepper powder, rice wine, glucose, silicon dioxide;

[0053] (2) Homogenization: Homogenize at a high speed of 8000r / min for 2min-3min;

[0054] (3) Filtration: filter with 100 mesh gauze, keep the under-sieve, and prepare shrimp oil;

[0055] (4) Spray-drying: Spray-dry the prepared shrimp oil, spray-drying parameters: feeding speed of pupa pump is 10mL / min-12mL / min, air inlet speed is 4m 3 / min-5m 3 / min, the air inlet temperature is 140°C-150°C, and shrimp oil powder is obtained;

[0056] (5) Cooling packaging: cooling the shrimp oil powder obtained by spraying to room temperature, and packing in stainless steel tanks or plastic bottles to obtain the finished product.

Embodiment 1

[0058] A kind of shrimp oil powder seasoning, is made up of following raw material of weight part:

[0059] 290 parts of shrimp oil enzymatic hydrolysis solution, 6 parts of white sugar, 12 parts of starch, 2 parts of yeast extract, 3 parts of monosodium glutamate, 1.2 parts of disodium nucleotides, 0.6 parts of disodium succinate, 8 parts of maltodextrin , 5 parts of β-cyclodextrin, 0.6 part of peach gum, 2 parts of ginger powder, 1 part of garlic powder, 1.1 part of white pepper powder, 6 parts of rice wine, 3 parts of glucose, 0.5 part of silicon dioxide;

[0060] Above-mentioned shrimp oil powder seasoning is made by following method:

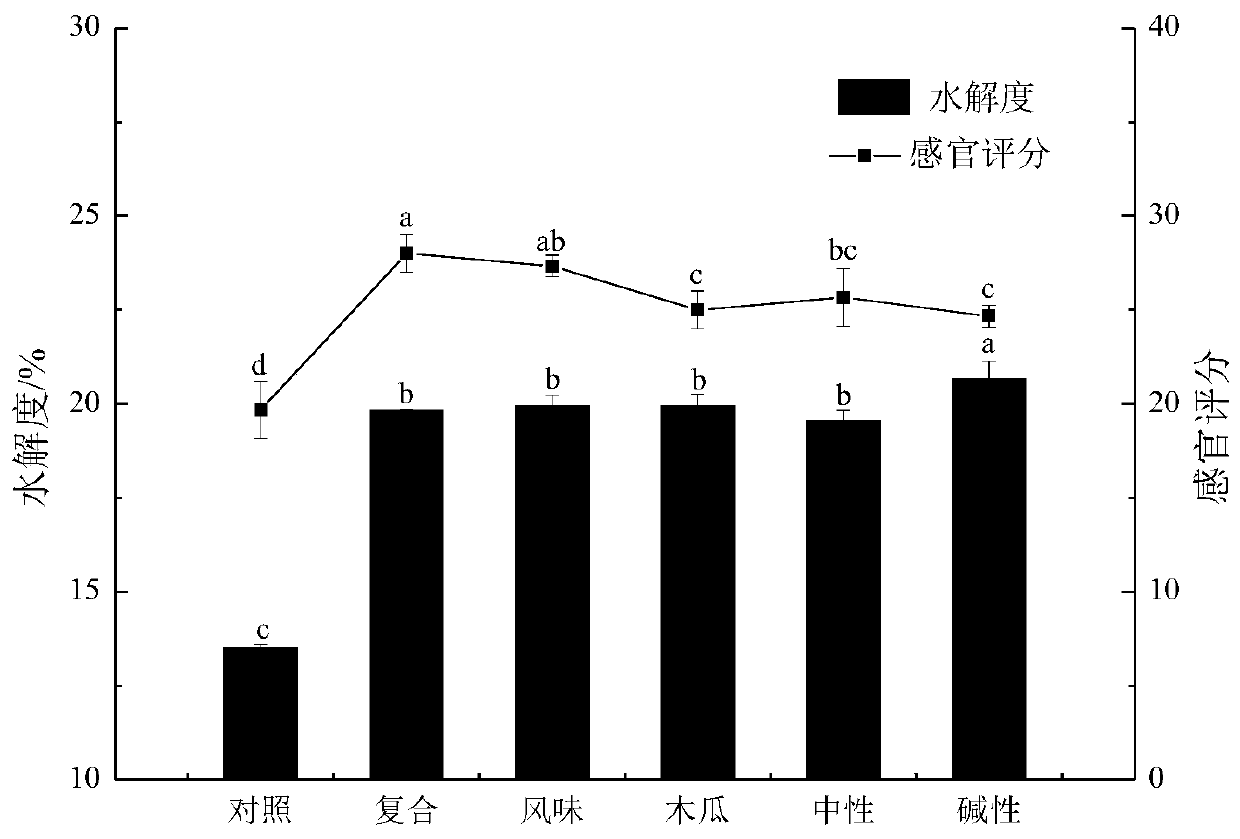

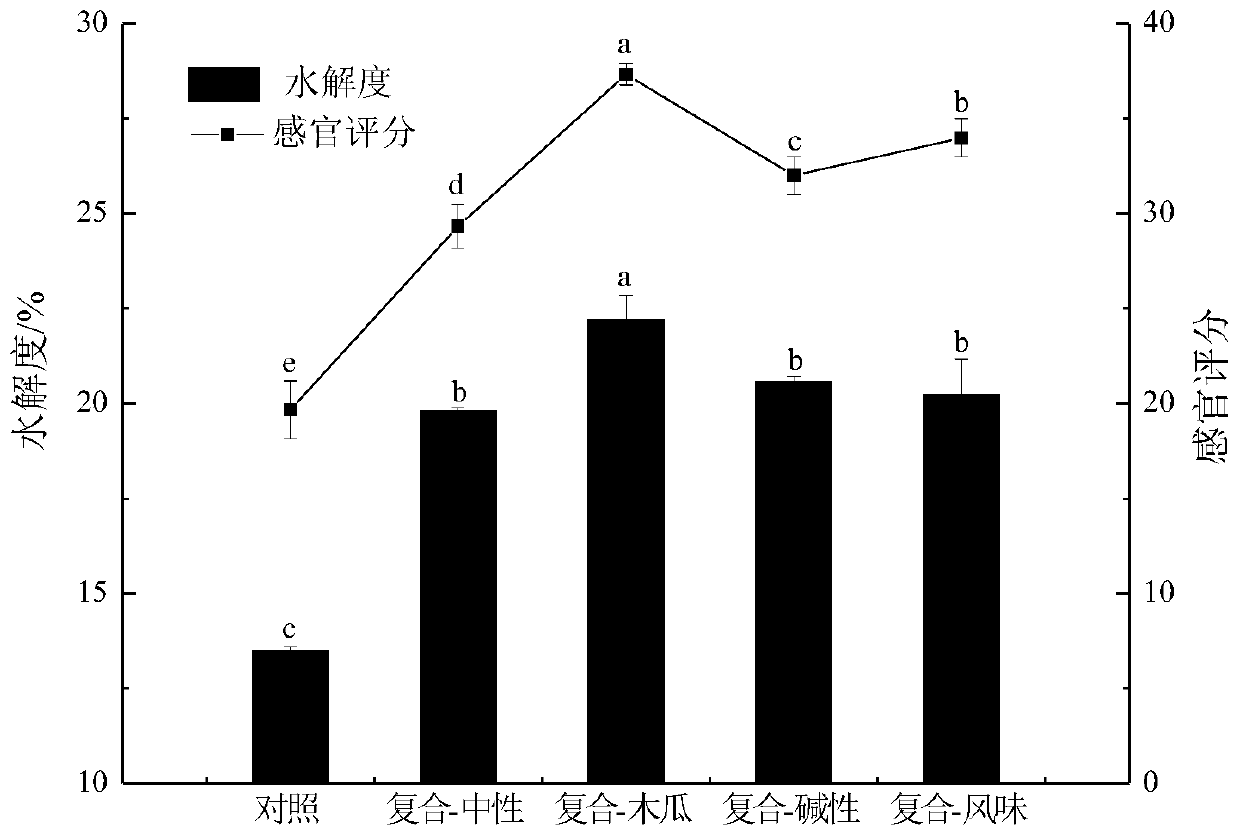

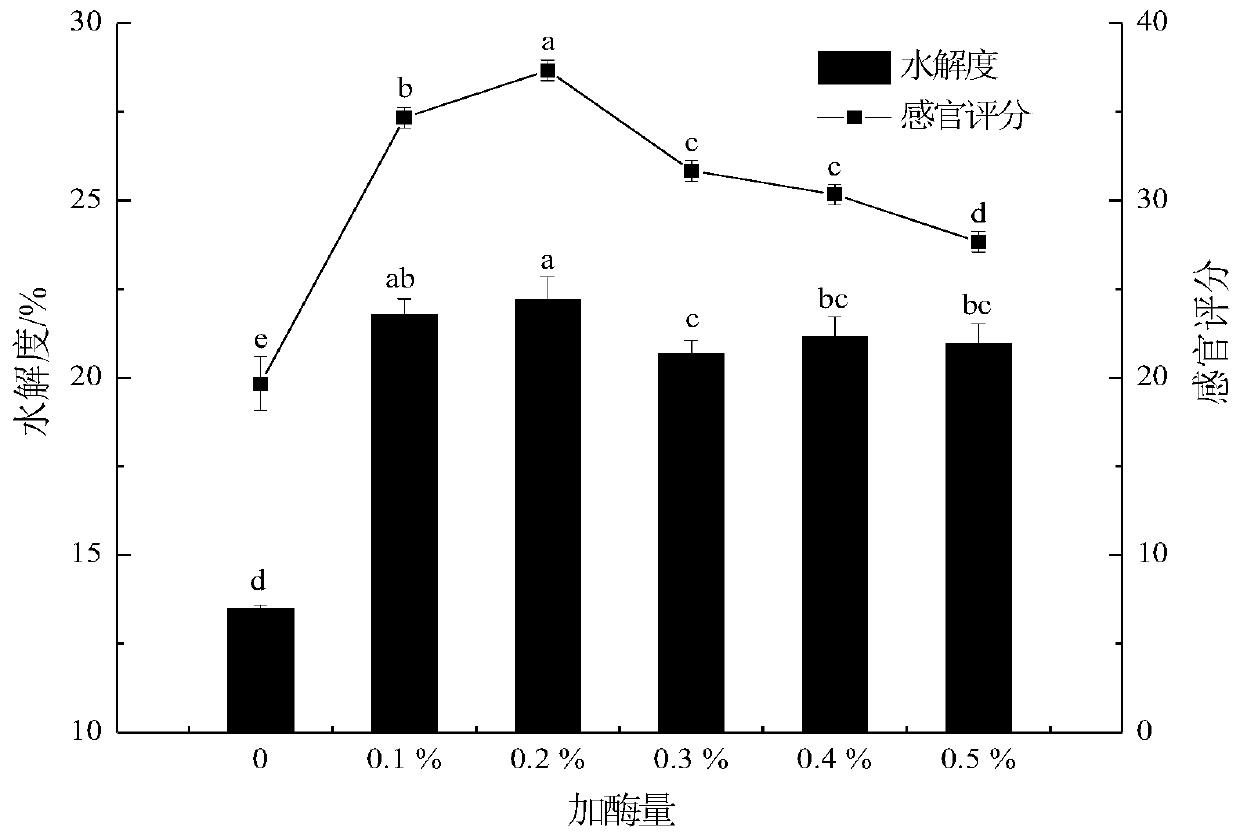

[0061] (1) Enzymolysis: get the enzyme that accounts for 0.2% of shrimp oil weight and add in shrimp oil, the kind of described enzyme is that mass ratio is 1: 1 compound protease and papain, and papain enzymatic activity is 1,000,000 U / g, so Said composite protease is alkaline protease and neutral protease with a mass ratio of 3:1, wherei...

Embodiment 2

[0071] A kind of shrimp oil powder seasoning, is made up of following raw material of weight part:

[0072] 280 parts of shrimp oil enzymatic hydrolysis solution, 5 parts of white sugar, 10 parts of starch, 1 part of yeast extract, 4 parts of monosodium glutamate, 1.5 parts of disodium nucleotides, 0.5 parts of disodium succinate, 10 parts of maltodextrin , 6 parts of β-cyclodextrin, 0.5 part of peach gum, 1 part of ginger powder, 2 parts of garlic powder, 1 part of white pepper powder, 5 parts of rice wine, 4 parts of glucose, 0.5 part of silicon dioxide;

[0073] Above-mentioned shrimp oil powder seasoning is made by following method:

[0074] (1) Enzymolysis: get the enzyme that accounts for 0.3% of shrimp oil weight and add in shrimp oil, the kind of described enzyme is compound protease and papain, and the mass ratio of the two is 1:1; Described papain enzyme activity is 1,000,000 U / g, the composite protease is alkaline protease and neutral protease with a mass ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com