Ozone-resistant low compressive deformation nitrile butadiene rubber and preparation method thereof

A technology of nitrile rubber and nitrile conversion, which is applied in the field of ozone-resistant low-pressure nitrile rubber and its preparation, can solve the problems of large compression set, poor ozone resistance performance, and poor low-temperature performance, so as to reduce the compression permanent Deformation, high ozone resistance, and the effect of increasing the degree of polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

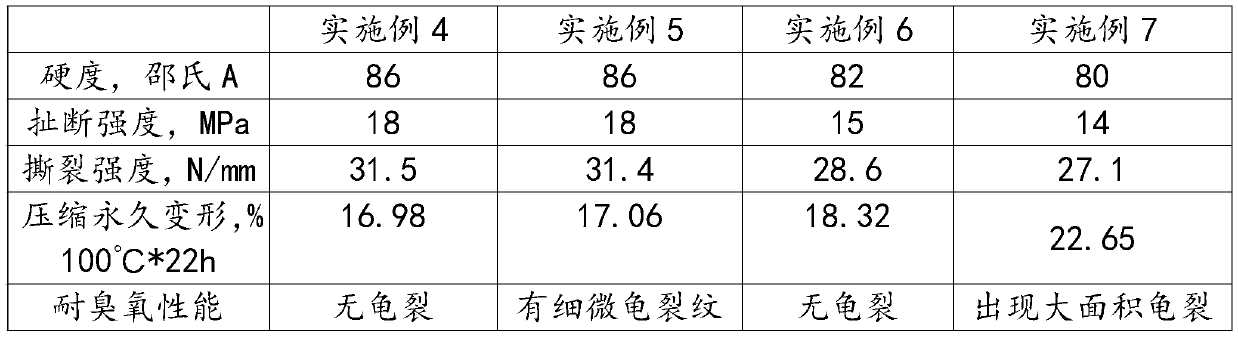

Examples

Embodiment 1

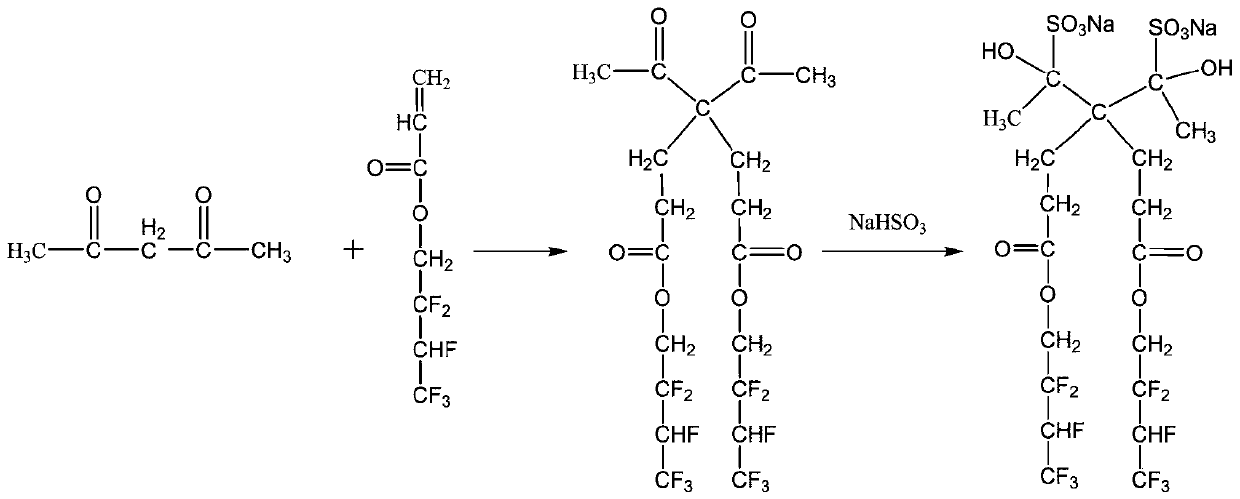

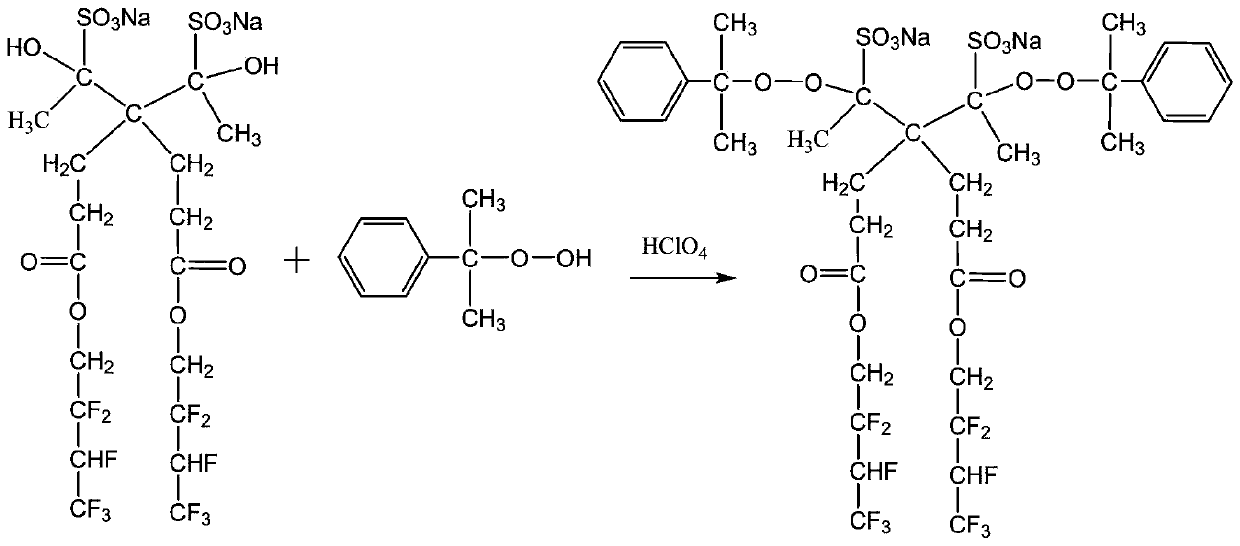

[0032] The specific preparation process of polyfluorinated vulcanizing agent is as follows:

[0033] Step 1: Add 3 mol of 2,4-pentanedione into diethyl ether, heat up to 70-80°C and reflux, then add 6.06 mol of hexafluorobutyl acrylate to it, react at constant temperature for 8-9 hours, and then carry out vacuum distillation to obtain fluorinated diketone;

[0034] Step 2: Prepare 6.3 mol of sodium bisulfite into a saturated sodium bisulfite solution, then add it to the reaction vessel, then add 3 mol of the fluorinated diketone prepared in step 1 to the reaction vessel, heat up to 50-60°C and stir for reaction 2-3h, and then filtered, and the filtered product was washed with deionized water and ethanol successively and then dried to obtain fluorinated dihydroxy sodium sulfite, such as figure 1 shown;

[0035] Step 3: Add 3 mol of fluorinated dihydroxy sodium sulfite and 6.15 mol of cumene hydroperoxide to the reaction vessel at the same time, then add 18 L of acetone soluti...

Embodiment 2

[0037] The specific preparation process of polyfluorinated vulcanizing agent is as follows:

[0038] Step 1: Add 3 mol of 2,4-pentanedione into diethyl ether, raise the temperature to 70-80°C and reflux, then add 3.01 mol of hexafluorobutyl acrylate to it, react at constant temperature for 8-9 hours, and then conduct vacuum distillation to obtain fluorinated diketone;

[0039] Step 2: Prepare 6.3 mol of sodium bisulfite into a saturated sodium bisulfite solution, then add it to the reaction vessel, then add 3 mol of the diketone fluoride prepared in step 1 to the reaction vessel, heat up to 50-60°C and stir for reaction 2-3h, and then filtered, and the filtered product was washed with deionized water and ethanol in turn, and then dried to obtain sodium dihydroxysulfite fluoride;

[0040]Step 3: Add 3 mol of fluorinated dihydroxy sodium sulfite and 6.15 mol of cumene hydroperoxide to the reaction vessel at the same time, then add 18 L of acetone solution to the reaction vessel...

Embodiment 3

[0042] The specific preparation process of polyfluorinated vulcanizing agent is as follows:

[0043] Step 1: Add 3 mol of 2,4-pentanedione into diethyl ether, heat up to 70-80°C and reflux, then add 6.06 mol of hexafluorobutyl acrylate to it, react at constant temperature for 8-9 hours, and then carry out vacuum distillation to obtain fluorinated diketone;

[0044] Step 2: Prepare 3 molmol of sodium bisulfite into a saturated sodium bisulfite solution, then add it to the reaction vessel, then add 3 mol of the fluorinated diketone prepared in step 1 to the reaction vessel, heat up to 50-60°C and stir for reaction 2 -3h, then filtered, and the filtered product was washed with deionized water and ethanol in turn, and then dried to obtain sodium fluoride hydroxysulfite;

[0045] Step 3: Add 3 mol of sodium fluoride hydroxysulfite and 3.05 mol of cumene hydroperoxide prepared in step 2 to the reaction vessel at the same time, then add 18 L of acetone solution to the reaction vesse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com