Preparation method of gradient mineralized bone extracellular matrix material

A bone extracellular matrix, gradient technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the irreversible damage of natural bone ECM scaffold materials, loss of minerals and growth active factors, affecting the biological regeneration and repair activity of scaffolds, etc. problem, to achieve the effect of good biomechanical properties, rich bioactive components, and low immunogenicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Preparation of porcine scapula specific part demineralized cancellous bone ECM material

[0052] 1) Take fresh pork scapula, wash it 4 times with sterile normal saline, take out the cancellous bone with a 6mm drill, and cut it into cylindrical bone pieces with a height of about 2mm with a scalpel;

[0053] 2) Rinse with sterile saline for 2 hours after collecting the materials, send them to the irradiation center, and sterilize them with 25w of radiation;

[0054] 3) Rinse with deionized water containing 20KIU / ml protease inhibitor for 3 times, each time for 10 minutes, to remove blood, adipose tissue and other impurities;

[0055] 4) Prepare high-temperature sterilized 1L glass bottles containing 500ml deionized water and 20 embedding boxes. Put 3 sterilized bone fragments into embedding boxes on a sterile operating table, put them into embedding boxes, put 10ml of deionized aqueous solution containing 15% acetone, and shake at a constant temperature of 10°C...

Embodiment 2

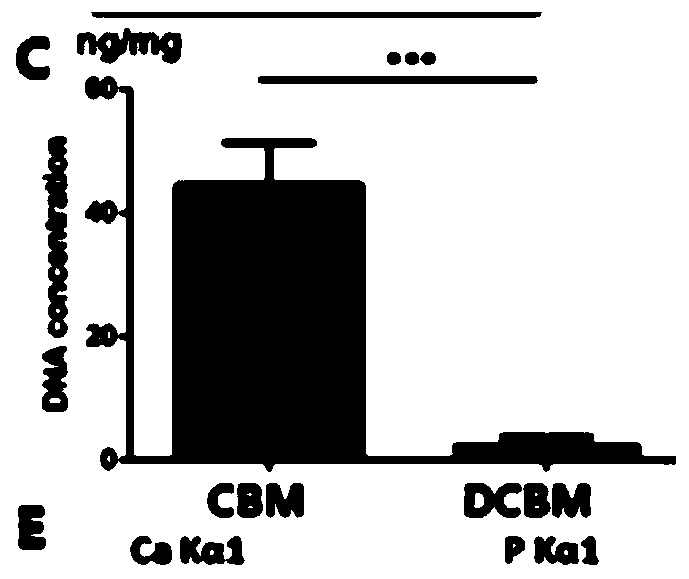

[0065] Example 2 Detection of bone ECM material with 90% and 60% mineralization degree of porcine scapula

[0066] 1) Take fresh pork scapula, wash it 4 times with sterile normal saline, take out the cancellous bone with a 6mm drill, and cut it into cylindrical bone pieces with a height of about 2mm with a scalpel;

[0067] 2) Rinse with sterile saline for 2 hours after collecting the materials, send them to the irradiation center, and sterilize them with 40w of radiation;

[0068] 3) Rinse with deionized water containing 10KIU / ml protease inhibitor for 3 times, each time for 20 minutes, to remove blood, adipose tissue and other impurities;

[0069] 4) Prepare high-temperature sterilized 1L glass bottles containing 500ml deionized water and 20 embedding boxes. Put 3 sterilized bone fragments into embedding boxes on a sterile operating table, put them into embedding boxes, put 10ml of deionized aqueous solution containing 15% acetone, and shake at a constant temperature of 10°...

Embodiment 3

[0083] Example 3 Characterization of bone ECM material with 90% and 60% mineralization degree of porcine scapula

[0084] 1) Take fresh pork scapula, wash it 4 times with sterile normal saline, take out the cancellous bone with a 6mm drill, and cut it into cylindrical bone pieces with a height of about 2mm with a scalpel;

[0085]2) Rinse with sterile saline for 2 hours after collecting the materials, send them to the irradiation center, and sterilize them with 5w of radiation;

[0086] 3) Rinse twice with deionized water containing 50KIU / ml protease inhibitor, each time for 10 minutes, to remove blood, adipose tissue and other impurities;

[0087] 4) Prepare high-temperature sterilized 1L glass bottles containing 500ml deionized water and 20 embedding boxes. Put 3 sterilized bone fragments into embedding boxes on a sterile operating table, put them into embedding boxes, put them into 10ml of deionized aqueous solution containing 10% acetone, and shake at a constant temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com