A kind of method that prepares alkyl phosphonate by peroxide

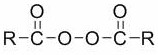

A technology of alkyl phosphonyl compounds and peroxides, which is applied in the field of preparation of organic compounds, can solve problems such as cumbersome operation, harsh reaction conditions, and large pollution, and achieve simple reaction operation and post-treatment process, mild reaction conditions, and high reaction efficiency. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

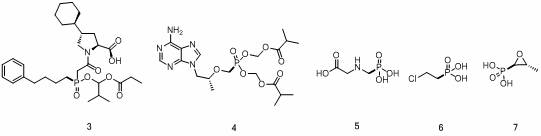

Method used

Image

Examples

Embodiment 1

[0051] Example 1: Synthesis of n-undecyl-bis(4-methylphenyl)phosphine oxide

[0052] Using lauroyl peroxide (abbreviated as LPO, CAS No.: 105-74-8) and bis(4-methylphenyl)phosphine oxide as raw materials, the reaction steps are as follows:

[0053] To LPO (199 mg, 0.5 mmol) was added cuprous chloride (9.9 mg, 0.1 mmol), 4,4'-dimethoxy-2,2'-bipyridine (10.8 mg, 0.05 mmol), acetone ( 1 mL) and bis(4-methylphenyl)phosphine oxide (57.5 mg, 0.25 mmol), the reaction was stirred at room temperature and monitored by TLC until the end of the reaction;

[0054] The crude product obtained after the reaction was separated by column chromatography (petroleum ether: acetone=4:1) to obtain the target product n-undecyl-bis(4-methylphenyl)phosphine oxide (yield 75%); The analytical data of the product are as follows: 1 H NMR (400 MHz, CDCl 3 ) δ 7.60 (t, J = 8.1 Hz, 4H), 7.26 (d, J = 7.7 Hz, 4H), 2.38 (s, 6H), 2.21 (d, J = 6.1 Hz, 2H), 1.60 (s, 2H), 1.41-1.32 (m, 2H), 1.31-1.17...

Embodiment 2

[0055] Example 2: Synthesis of n-undecyl-bis(4-chlorophenyl)phosphine oxide

[0056] Using LPO and bis(4-chlorophenyl)phosphine oxide as raw materials, the reaction steps are as follows:

[0057] To LPO (199 mg, 0.5 mmol) was added cuprous bromide (14.3 mg, 0.1 mmol), 1,10-phenanthroline (18.2 mg, 0.1 mmol), ethanol (1 mL) and bis(4-chlorobenzene base) phosphine oxide (67.8 mg, 0.25 mmol), 60 o C stirring reaction, TLC monitors to the end of reaction;

[0058] The crude product obtained after the reaction was separated by column chromatography (petroleum ether: acetone = 4:1) to obtain the target product (yield 83%). The analytical data of the product are as follows: 1 H NMR (400 MHz, CDCl 3 ) δ 7.6-7.59 (m, 4H), 7.43(d, J = 6.9 Hz, 4H), 2.26-2.15 (m, 2H), 1.64-1.51 (m, 2H), 1.40-1.31 (m,2H), 1.28-1.16 (m, 14H), 0.85 (t, J = 6.9 Hz, 3H).

Embodiment 3

[0059] Example 3: Synthesis of n-undecyl-bis(thienyl)phosphine oxide

[0060] With LPO and dithienyl phosphine oxide as raw materials, the reaction steps are as follows:

[0061] To LPO (199 mg, 0.5 mmol) was added cuprous cyanide (5.4 mg, 0.06 mmol), 2,9-dimethyl-1,10-phenanthroline (10.4 mg, 0.05 mmol), ethyl acetate ( 1 mL) and dithienylphosphine oxide (53.6 mg, 0.25mmol), 40 o C stirring reaction, TLC monitors to the end of reaction;

[0062] The crude product obtained after the reaction was separated by column chromatography (petroleum ether: acetone = 4:1) to obtain the target product (yield 80%). The analytical data of the product are as follows: 1 H NMR (400 MHz, CDCl 3 ) δ 7.69 (t, J = 4.1 Hz,2H), 7.58 (dd, J = 6.9, 3.3 Hz, 2H), 7.20-7.15 (m, 2H), 2.31-2.21 (m, 2H),1.74-1.59 (m, 2H), 1.37 (dd, J = 14.1, 7.0 Hz, 2H), 1.31-1.16 (m, 14H), 0.85 (t, J = 6.9 Hz, 3H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com